|

Here are some basic rules of thumb on end mill selection Navigating the vast array of end mills available in the market can be a daunting task, especially when precision is paramount. To aid in this process, we've outlined a step-by-step guide that addresses crucial considerations for selecting the optimal end mill for your machining needs.

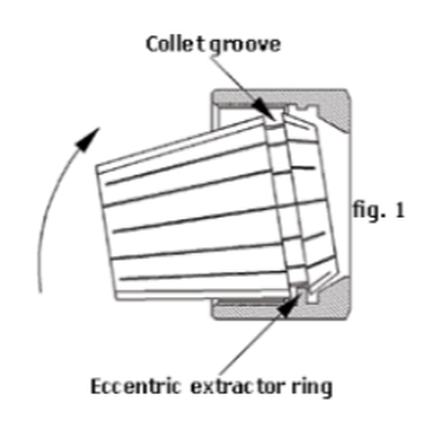

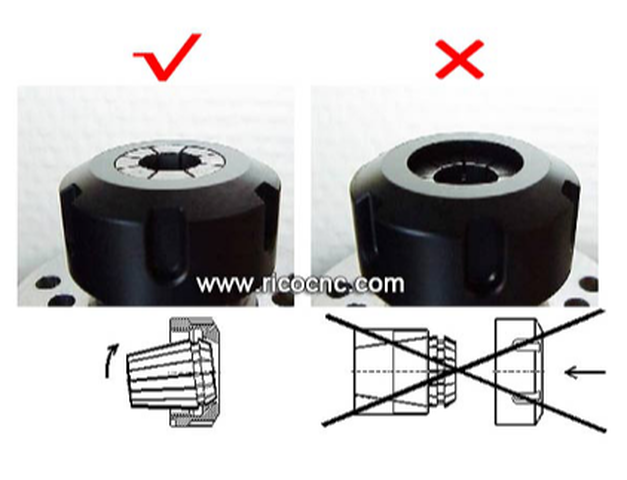

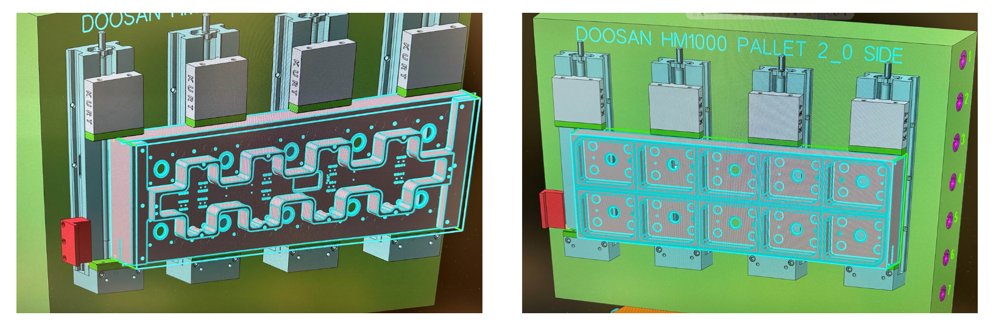

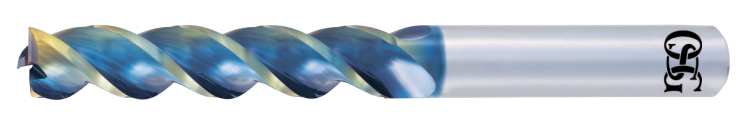

Step 1 – Material Identification: Identify the exact material, its condition (billet, forging, etc.), and hardness (HRC). This information directs you to the Non-Ferrous or Ferrous section of our catalog. Step 2 – Operation Type: Determine whether you'll be roughing, finishing, or both. This guides the choice of the number of flutes and the need for chip breakers. Step 3 – Programming Style: Choose between traditional programming, high efficiency programming (HEM), or a combination. This decision influences the number of flutes (Step 8). Step 4 – ADOC (Axial Depth of Cut): Determine the maximum axial depth of cut the tool will experience in the part. This information helps decide the length of cut (LOC) to deploy. Step 5 – Reach Consideration: Evaluate obstacles to clear and depths to reach. If necessary, consider a reduced necked tool to maintain length of cut while reaching deeper positions. Step 6 – Tool Diameter Selection: Consider the machine taper, cut depth, reach, and part geometry. Keeping the tool diameter under 3/4" for 40-taper machines and adapting the diameter to programming style, cut depth, and reach requirements. Keep in mind what programming style (Step 3) you’re using as HEM can employ smaller diameters than you may be used to. Decide on your cut depth (Step 4). For traditional programming keep it <2xDia., for HEM keep it below 4xDia. Decide on your total reach depth (Step 5). If needing to machine 4xDia. look at a necked tool to maintain strength and minimize deflection. Step 7 – Corner Radius: Determine if your part requires a corner radius. Running a corner radius on an end mill can extend its life and is especially beneficial for pre-finishing. Step 8 – Flute Count: Consider the material and programming type to determine the ideal flute count. Non-Ferrous machining typically requires 2-3 flutes for traditional programming and 3-5 for HEM, while Ferrous machining may need 4-5 for traditional programming and 5-7 for HEM. Step 9 – Tool Holder Selection: Always opt for the most rigid and accurate tool holder with minimal runout. Keep the Total Indicator Runout (TIR) below 0.0005 at the tip of the tool for optimum tool life and success. Consider the use of a side lock holder for specific applications. Remember, our team at Next Gen Tooling is always available to assist you in selecting the correct product. By following these guidelines, you'll navigate the selection process with confidence, ensuring precision and efficiency in your machining operations.

0 Comments

The number of flutes on a carbide end mill significantly influences its performance across various machining applications. How many flutes do you need? The simple answer: It depends. Obviously there are a quite a number of other factors that impact an end mills performance such as helix angel, edge prep, gullet depth and radius. We can't tackle everything in this article, but hopefully this helps you get a better understanding of why there are different numbers of flutes on end mills. Below is an overview of the advantages and disadvantages associated with end mills featuring different flute counts, along with recommendations for materials based on ISO 513 categories (P, M, K, N, S, H) Single Flute End Mills

2-Flute End Mills

3-Flute End Mills

4-Flute End Mills

5-Flute End Mills

6-Flute End Mills

7-Flute End Mills

8-Flute End Mills

0-Flute End Mills

Advantages of Higher Flute Counts in |

|

More Designs for Roughing

Speroni Tool Presetter: A Fabricator Finds Dramatic Time and Tool Cost Savings in an Unusual Place

12/15/2020

To keep up, Alpha Granite has invested in several advanced CNC machines, diminishing or altogether eliminating many of the laborious and time-consuming processes. Despite the technological advances, there was still a bottleneck that frustrated owners Denis and Sonia Phocas.

“Measuring tools in the stone industry was always a very laborious process,” explained Denis Phocas. “It’s archaic. You get wet, dirty and it takes a really long time. In reality, the process destroys tools because employees know the time and effort involved, so they tend to skip the necessary measuring intervals [ultimately cutting tool life roughly in half].

Dressing of the tools is also skipped, as this process needs to be done after a set amount of linear feet of work. In essence, the tools need to be measured and sharpened at set intervals to increase life.”

The traditional measuring process is manual. Measuring height and diameter to set up and inspect tools requires handheld instruments like calipers. Phocas explains how important accurate and sharp tools are to cutting stone profiles.

Since each profile requires several passes by six or seven different tools, each dependent on the accuracy, and more delicate than the one before. In other words, if the first tool isn’t dialed in right, the profile shape will be deformed, tools wear faster and the hours spent preparing them are wasted.

“Finding the center of one tool is hard enough,” he said. “Finding the center in relation to six others is very difficult.”

Phocas had heard about tool presetters, essentially a powerful microscope with a high-resolution monitor and basic computing power. It allows for precise inspection and measurement of tool edges. The process is relatively new to the stone industry and mostly limited to larger fabricators. As he explored further, Phocas began to understand why — only the big guys could afford them.

The presetters he saw from his distributers were big, expensive and, frankly, had more bells and whistles than a family-owned independent shop like Alpha Granite would need. Phocas recalled thinking, “It was such a major expense. Who needs to spend $60,000 on something you don’t need fully automated? There had to be a smaller solution.”

Phocas approached suppliers about entry-level options, but they continued pushing more expensive options. He got creative and found a metalworking supplier, Big Kaiser Precision Tooling in Hoffman Estates, IL, that might be able to help. The Speroni STP Essentia they offered featured a compact bench-top design, could work with any brand of router tools and handle the more complex tool profiles in stone cutting with ease. Most importantly, it was much less expensive than the other options he had found.

After working closely with a representative from Big Kaiser, even trying out an Essentia in his shop, Phocas was convinced and decided to purchase one. While there are significantly fewer types of tools used for profile cutting, this new capability and process would be an adjustment at first, starting with installation.

“I had never worked with one of these,” said Phocas. “It’s a precision tool. I wouldn’t call it daunting, but the process was interesting. We installed it in the workshop manager’s office because we wanted to keep it in a clean environment and because it’s got a computer hooked up to it. In the end, the installation process was pretty straightforward.”

“Once we got used to it, it was very easy,” said Phocas. “Our employees simply love the Essentia and now depend on it.”

The results have been undeniable. “The Essentia quickly tells you if a tool is out of shape,” explained Phocas. “I can prepare a set of tools in about 10 minutes, put them on the machine and start running. Whereas, with the old system it would take me anywhere between two to three hours, re-measuring and re-dressing while machines sat idle. We think our tool life has improved by 35 to 45 percent as well. It’s just phenomenal.”

Alpha Granite isn’t stopping there. In the near future, they’ll install software on their CNC routers that will precisely monitor the amount of linear feet each tool is working. This data will make tool recalibration even more streamlined. As things stand now, they have scheduled days for using the Essentia to recalibrate tools. With the new software, they’ll be able to recalibrate on-demand, so to speak, right when a tool has reached its manufacturer-recommended linear feet.

The addition of the Essentia has sparked dramatic process improvements. While presetters aren’t foreign to stonework, they aren’t all that common at fabrication shops like Alpha Granite. But if the results are any indication, other independent fabricators may want to get creative in their exploration of tool management options too.

The full story about Alpha Granite & Tile can be found in the April 2018 issue of Stone World or online at: www.stoneworld.com.

Shrink fit holders are the most accurate for TIR as the toolholder engages completely around round shank tools with a bore tolerance of -0.0001" to -0.0003". As high performance end mills have tightened shank tolerances to the same range of -0.0001" to -0.0003" they have used finer and finer grain grinding wheels which give the shanks a 'shiny' appearance.

Shiny means that the superfinished shank has a lower coefficient of friction. So, although the TIR is tighter, the shank is more "slippery". End mills traditionally had surface finish of about 8 μin on the tool shank. But that's changed. It's been recommended that tool shanks used in shrink fit holders should not have a finish finer than 16 μin. for optimum holding power, but tell that to the guy who just superfinished the end mill to a super cocncentric tolerance that you don't want it looking that good.

Everyone knows that the last thing you want is for the end mill to slip in the middle of a heavy cut or on the finishing pass of a high tolerance part. These 'hi performance' end mills, often times have higher helix angles which are great for ejecting chips but also create a higher pull out force on that slippery shank. And reducing the helix angle is not the answer.

We already know that the gripping pressure is a function of the interference between the tool shank and the shrink fit toolholder bore. Most shrink fit holders have a already bore surface finish of between 12 μin. and 16 μin. So they are ground to a very high tolerance and have about the same surface finish as the toolholder shank.

End mill manufacturers and machinist have tried a variety of methods over the years to stop the tools from pulling out. This has ranged from grit blasting the shank to rubbing chalk on the shank, but most everyone in the industry has felt that the problem really needs to be addressed by the longer life toolholder rather than the replaceable cutting tool.

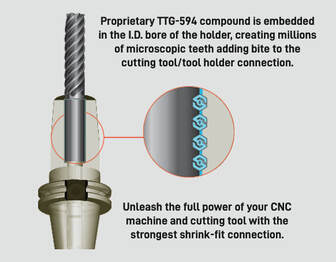

That's the problem that Techniks wanted to address. Techniks claims that their "proprietary non-slip TTG594 compound virtually fuses the tool shank with the shrink fit toolholder."

ShrinkLOCKED Toolholders eliminate cutting tool pull-out and provide 4X the friction drive force compared to un-treated shrink holders.

Techniks arrived at their 4x the holding power comes from torsion testing vs. a standard shrink fit toolholder. They used a ¾” carbide gage pin in a standard holder and found the torque at which the tool will spin in the bore.

They then tested the ShrinkLOCKED holder using the same test.

According to Greg Webb, at Techniks,

"We actually could not find the point at which the tool would spin in the ShrinkLOCKED holder as we broke the carbide gage pins at 4x+ times the torque of the standard holder. The holding power is greater, we just have not found a way to measure this, so we kept our claims conservative at 4x."

Technical Support Blog

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference.

If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website.

Authorship

Our technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada.

Archives

July 2024

June 2024

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

December 2022

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

February 2022

December 2021

November 2021

October 2021

September 2021

August 2021

July 2021

June 2021

May 2021

April 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

August 2020

July 2020

June 2020

May 2020

March 2020

February 2020

January 2020

September 2019

August 2019

July 2019

June 2019

May 2019

March 2019

January 2019

September 2018

June 2018

April 2018

February 2018

December 2017

November 2017

October 2017

August 2017

June 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

August 2016

March 2016

February 2016

January 2016

November 2015

August 2015

July 2015

May 2015

April 2015

March 2015

November 2014

August 2014

July 2014

December 2013

November 2013

September 2013

July 2013

March 2013

December 2012

March 2012

November 2011

May 2011

March 2011

January 2011

December 2010

November 2010

October 2010

Categories

All

5th Axis

Aerospace

Allied Machine

Aluminum Oxide

Angle Head

AT3

Balance

Bellmouthed Hole

Big Daishowa

Big EWA Automatic Boring

Big Kaiser

BIG Plus

Blue Photon

Bone Screws

Boring Tool

Carbide

Carmex Precision

CBN

Centerline Deviation

Ceramic Black

Ceramic End Mill

Ceramic Inserts

Ceramic Oxide

Ceramic Whiskered

Ceramic White

Chamfer

Champion Tool Storage

Chip Breaking

Circular Saw

Class Of Fit

CNC Lathe Tooling

Collet

Collet Chuck

Collet ER

Collet TG

Composites

Covid-19

Deep Hole Boring

Deep Hole Drilling

Drilling

Dual Contact

Dyna Contact Gage

Dyna Force Tool

Dyna Test Bar

EMO

End Mill

Exotap

Facemill

Fixturing

Fretting

Gaylee Saw

Hard Turning

Heimatec

Helical Interpolation

Hohl Shaft Kegel

How Its Made

HSK A

HSK-A

HSK E

HSK-E

HSK F

HSK-F

HXL Tap

Hy Pro Tap

Hy-Pro Tap

IMTS

Jergens

Jergens OK-Vise

Kurt

Lang

Live Tooling

MA Ford

Maintenance Cart

Mapal

Martindale Saw

Material: Aluminum

Material: CFRP

Material: D2

Material: Hastelloy

Material: Inconel

Material: Peek

Material: Stone

Material Titanium

Material: VC 10

Material: VC-10

Metric Course Thread

Metric Fine Thread

Metric Thread Chart

Microconic

Micromachining

ModLoc

Modular

Mogul Bars

MPower

NextGen Tooling

No Go Too Loose

NTK

NTK HX5

On Site Training

OptiMill-SPM

OSG Tap & Die

Oversized Thread

Parlec

PCD

PCT Firm Hold

Platinum Tooling

Projection Length

Pull Studs

Reamer

Retention Knob

Rotary Toolholders

Rotary Toolholders BT

Rotary Toolholders CAT

Rotary Toolholders HSK

Rotary Toolholders Hydraulic

Rotary Toolholders Shrink

Rough Thread

Runout

Runout Axial

Runout Radial

Safe-Flex

Saw Selection

Short Tap Life

Sialons

Silicon Nitride

Smart Damper

Speed Increaser

SpeedLoc

Speroni STP Essntia

Spindle Mouth Wear

Surface Roughness Ra

Surface Roughness RMS

Swiss

Swiss Machining

Taper Wear

Tapping Feed

Tapping; Form

Tapping IPM

Tapping: Roll

Tapping RPM

Tapping Speed

Tap Tolerance

Technical Training

Technicrafts

Techniks USA

Thread Milling

Thread Whirling

T.I.R.

Tolerance

Toolchanger Alignment

Toolholder Taper

Tool Presetter

Torn Thread

Troubleshooting

UNC Thread Size

Undersized Thread

UNF Thread Size

Unilock

Vises

Washdown Tool

Workholding

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed