|

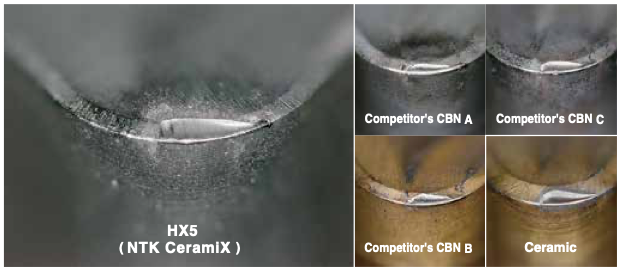

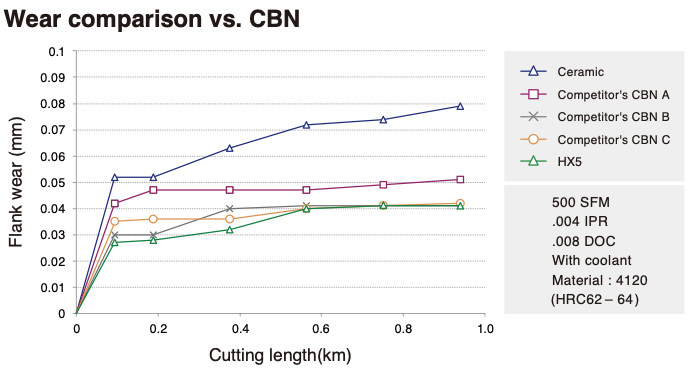

NTK CeramiX HX5 replaces CBN NTK developed this latest game changing ceramic material NTK CeramiX HX5 to replace CBN. As a ceramic cutting tool specialist, NTK has been researching new advancements for ceramics in the industry for decades. They recently introduced a new grade that matches CBN on performance. The new CeramiX "HX5" grade provides a cost saving solution for hard turning applications. It's designed for Hard Turning with continuous cut in the Hardness range of 55 to 66HRc

0 Comments

Over the years, many of our customers have come to us because they were regularly breaking taps.

This meant that the holes had to go from a depth of .150" to .190". The 2-56UN thread’s major diameter was .086", and the drill diameter .070".

Repeatability was nearly impossible on his CNC equipment, and he literally came in every Saturday to tap the holes by hand. When he started talking with us, he was breaking his taps after only 20 holes — an extraordinarily short tool life. By re-examining his technology, and switching to Carmex Precision thread milling, he was able to accomplish the threading of 683 holes with a single thread-mill on his CNC equipment. Despite the number of passes, the wear factor between the first and the last holes could only be measured in tenths, and the customer was able to get the thread detail back to its original .150" full thread depth. Perhaps just as important, his Saturdays are now “tap-free.” We are very excited to announce that we are now able to offer on-site technical training to YOUR machinists at YOUR location! This is offered at no charge to customers who use any of the manufacturer's whom we represent in California and Nevada. However, just because you don't purchase things from us, don't feel left out! We also offer on-site topic specter training on any of the following topics for $150/hour. Each presentation lasts about 2 hours. The presentations last approximately 45-60 minutes with the remaining time for Q&A and discussion about unique applications in your facility.  Training Classes Available: Machining 101

Advanced Part Manufacturing:

Complex part shapes have time consuming part loads to assure the part is properly nested before machining. Blue Photon makes a hard to load part easy and reduces the number of loads. Traditional workholding does not usually utilize a machine’s full capabilities because of limited machining access therefore multiple workholding fixtures and process steps are required. *Labor cost per part was calculated @ $50.00 per hour, based on 21 hours run time per (3) 8 hour shifts/5 day work weeks. 6,240 total hrs. per year How the blue photon system realized reduce labor costWith Blue Photon workholding technology, once the part is bonded to the transfer tool it can be loaded into all machines using the same machine mounted workholding fixture system such as Erowa, System 3R etc. The workpiece loads in seconds.

The ability of Blue Photon workholding technology to hold the workpiece on one side providing 5 and in some cases 6 side machining access is unheard of when machining castings and other near-net shape parts. There is also reduced foot print for this cell and reduced capital investment to create the cell because multiple operations can be done in one workholding. Mark Your calendar: May 10, 2016 and join us in Los Angeles for Aerospace Composites & High Temperature Alloys Training OSG's Aerospace training for composites & high temp alloys covers: Difficulties when machining, troubleshooting, the best tools for aerospace machining and more! What You’ll Learn

Who Should Attend: This seminar will benefit anyone curently machining or interested in learning more about machining composites and high temp alloy materials. Machinists, operators, manufacturing engineers, programmers, etc. Seminar Agenda

9:00 - 12:00 - Composites

1:00 - 4:00 - High Temp Alloys

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed