|

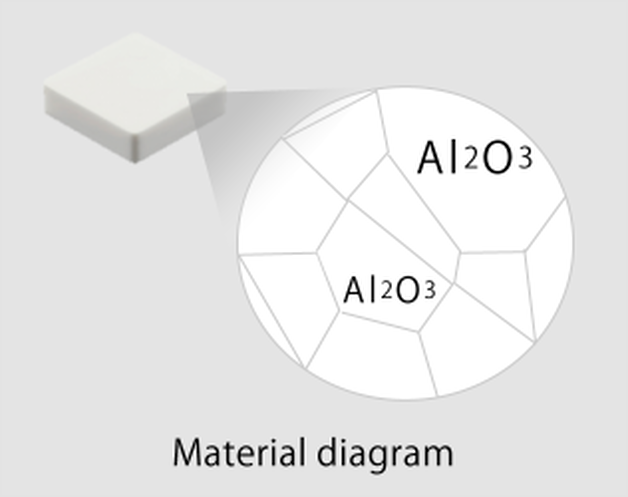

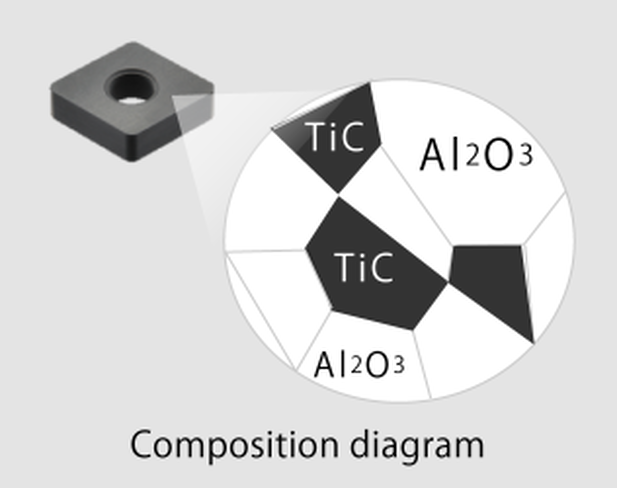

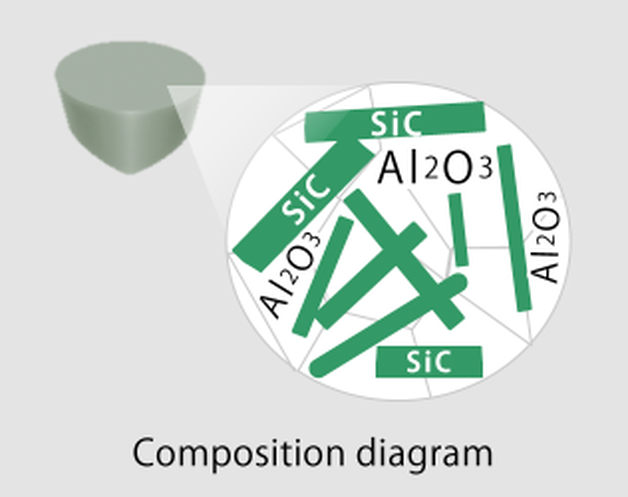

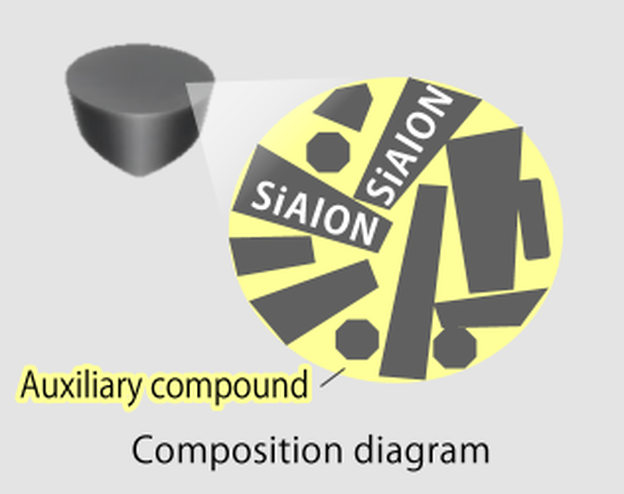

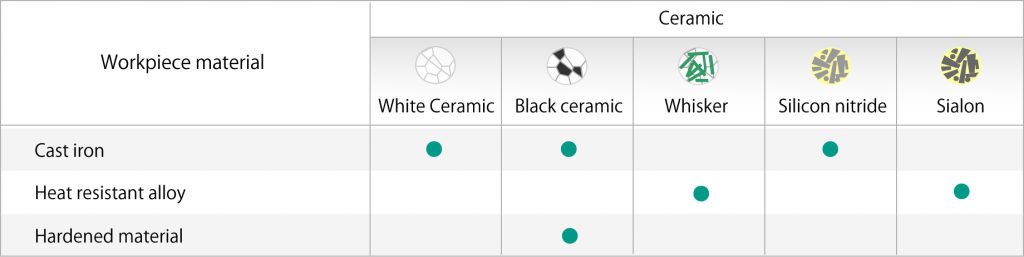

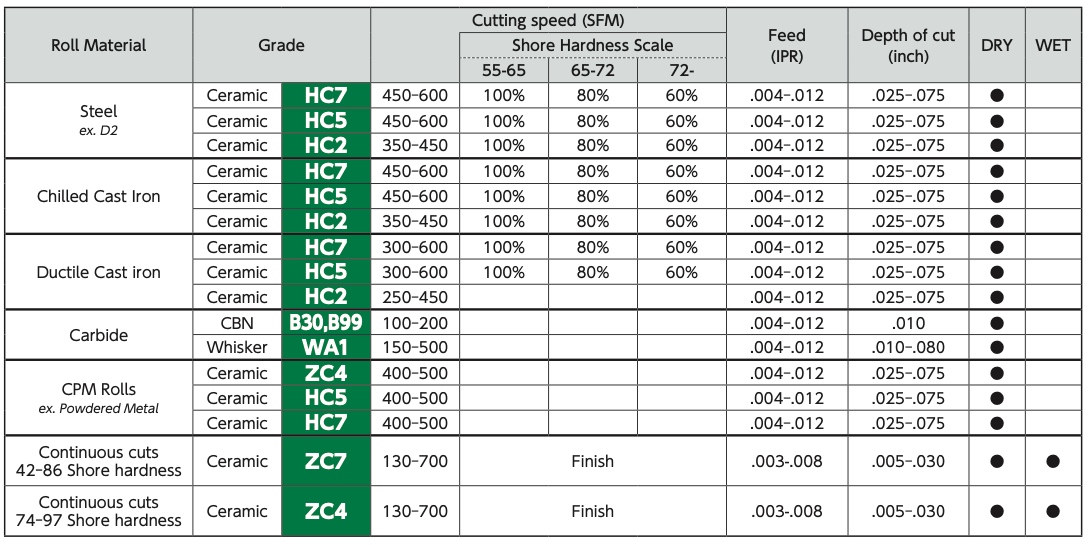

A very helpful article from our friends at NTK Cutting Tools. When you hear the word “ceramic”, the first thing people may think of is the “white” material used for plates and sanitary ware (toilets). But that type of ceramic is just one of a number of ceramics. There are as many as five ceramics used for cutting tools.In this article, we will introduce the 5 types of ceramic used in cutting tools. What is ceramic in the first place?IIn a broad sense, ceramics are a blend of metal or nonmetal with oxygen (O), nitrogen (N), carbon (C), etc., and this baked material is used as a cutting tool. The ceramic used in cutting tools is roughly available in two types of “Alumina ceramic” (Al2O3) and “silicon nitride (Si3N4) ceramic” made by blending various additives with the main ingredients to develop specific characteristics. It is further subdivided by the addition of various additives to the main ingredients. Al2O3 : Alumina-based ceramics1. White Ceramic Alumina (Al2O3) is the main component of ceramic, and is called white ceramic because of its color. In fact, the same ingredients are in jems like rubies and sapphires (Al2O3) The main difference is that ruby and sapphire are single crystals (particles of one large mass), while alumina is polycrystalline (a collection of multiple particles). Alumina is hard and chemically stable. Taking advantage of its properties, it is used in high-speed finishing of cast iron. 2. Black Ceramic Titanium carbide (TiC) is added to alumina, and this is called black ceramic because of its color. The addition of titanium carbide results in higher hardness, than white ceramic, and suppresses deformation of the cutting edge due to heat; even at high temperatures. Taking advantage of its properties, it is used in high-speed finishing of hardened materials up to about HRC65. 3. Whisker It is a ceramic in which silicon carbide (SiC) is added to alumina. Do you know why it’s called whisker ? Silicon carbide has a needle-like shape similar to a “animal beard”, so it is now called whisker (ceramic). By intertwining silicon carbide with each other, the progression of cracks due to impacts during cutting is suppressed, and cracks are prevented. In addition, it has a resistance against sudden temperature changes. Taking advantage of these properties, it is widely used for heat-resistant alloy processing. Silicon nitride, Si3N45. Silicon Nitride Silicon nitride (Si3N4) is the main component, and a special feature is that the particles are needle-like, different from the alumina compound. By intertwining needle-like particles, the progression of cracks due to impact during cutting can be greatly suppressed, preventing cracks. Taking advantage of these properties, it is used in high-speed roughing of cast iron. 5. Sialon Silicon nitride (Si3N4), Aluminum (Al), and oxygen (O)are blended to form SiAlON, which is an initial of its component elements. Sialons, like silicon nitride, have needle-like particles. Needle-like particles intertwine to withstand impact during cutting. In addition, the effect of the added alumina component improves heat resistance over silicon nitride, and has excellent high temperature resistance characteristics. Taking advantage of these properties, it is used in high-speed processing of heat-resistant alloys. The table below shows typical machining application examples of ceramic cutting tools.We hope this column gave you a better understanding of the types, differences, and features of ceramic materials.

Ceramic cutting tools must be used according to the material to be machined, but they can be processed up to 20 times faster than carbide tools. Increase productivity with ceramic cutting tools for your material applications.

0 Comments

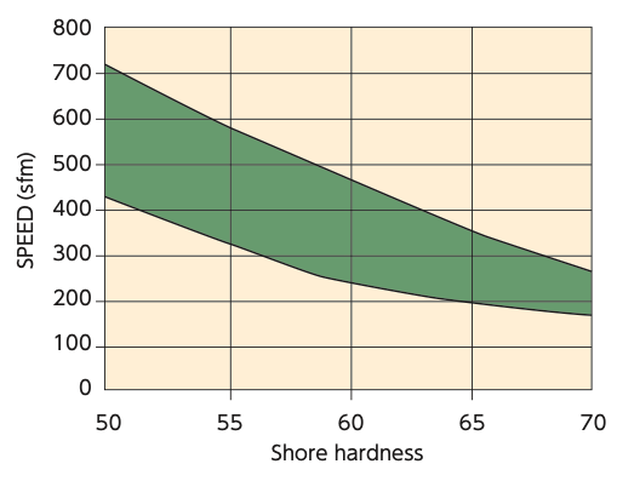

Here are some simple quick tips when you are machining machining hard materials.

We are very excited to announce that we are now able to offer on-site technical training to YOUR machinists at YOUR location! This is offered at no charge to customers who use any of the manufacturer's whom we represent in California and Nevada. However, just because you don't purchase things from us, don't feel left out! We also offer on-site topic specter training on any of the following topics for $150/hour. Each presentation lasts about 2 hours. The presentations last approximately 45-60 minutes with the remaining time for Q&A and discussion about unique applications in your facility.  Training Classes Available: Machining 101

Advanced Part Manufacturing:

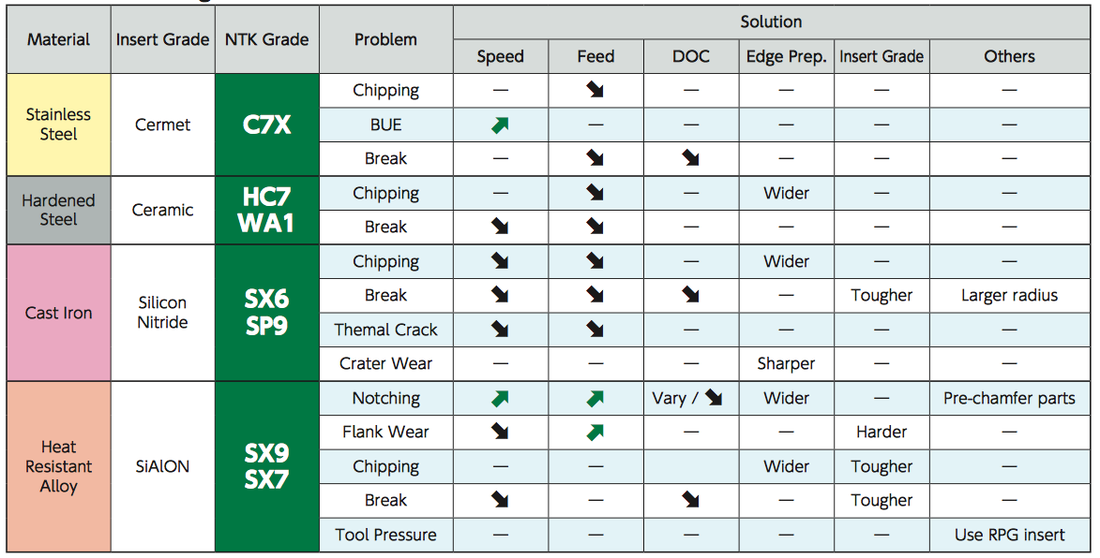

NTK's industry leading line of ceramic cutting tools recently expanded with new solid CERAMIC end mills! You can see our product announcement here: NTK now offers SX9 Ceramic End Mills for Cutting Exotic Alloys which contains the various features. Below is the technical info on how to run the NTK Ceramic End mills and a troubleshooting guide. NTK's SX9 cermaic end mill grade can run at speeds of 2000 SFM. The line-up includes 4 and 6 flutes in inch and metric versions. Again, you can learn more about on our Blog Post. Solid ceramic end mills are made with SX9 SiAlON grade substrate which features a balance of toughness and wear resistance. It's suitable for even the most demanding applications. First Step Machining Procedures

Gernarel Recomendations for machining heat resistant alloys & PH stainless steel

As with any other techncial questions please get in touch with us on our CONTACTS page and we can provide both over-the-phone troubleshooting or schedule at time for on-site techncial training.

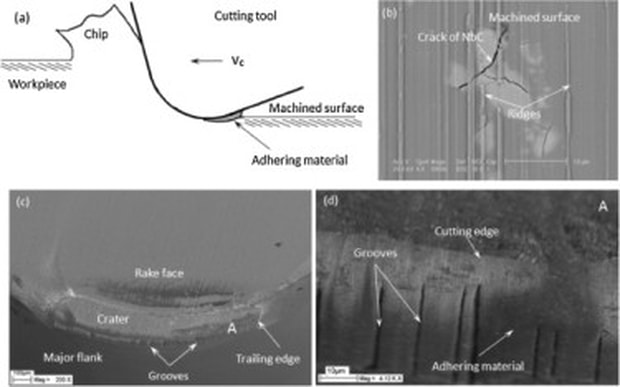

Ceramic tools have high resistance to heat and to wear and can be used to machine metals that are extremely hard, and they are chemically stable. These attributes allow them to be used to machine metals at high cutting speeds and in dry machining conditions because it is not necessary to reduce temperatures on the cutting edges of these tools. However, these favorable properties are exchanged in machining for lower toughness when these tools are compared with carbide tools. This deficiency can be offset by selecting an appropriate ceramic cutting grade and the type of tool. Ceramic tools are based primarily on alumina (Al2O3) and silicon nitride (Si3N4) compounds and are available in a variety of grades that include ceramics mixed with other materials and reinforcing whisker materials that make them harder. Oxide ceramics

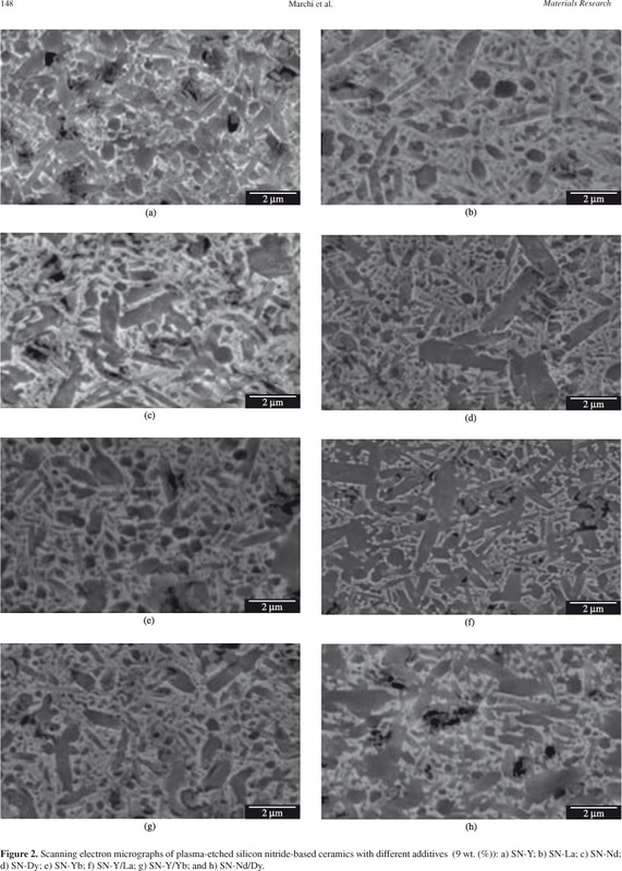

The materials are molded at pressure more than 4,000 psi and they are sintered at approximately 3,000 degrees F. This process accounts in part for the high density and hardness of these tools. Oxide ceramics are used primarily for rough and finish turning, for grooving of gray and nodular cast iron and for continuous cutting at high cutting speeds without the use of coolant. Ceramic tools are stable at extreme temperatures as high as 4,000 degrees F., unlike carbide and cement tools that contain metallic binders and begin to soften at temperatures greater than 1,000 degrees F. Whiskered ceramicsReinforced or whiskered, ceramics use extremely fine-grained silicon-carbide crystals that are called “whiskers” because they resemble small hairs under a microscope to reinforce and toughen basic ceramic compounds. In ceramic tool materials, single-crystal silicon carbide whiskers, on the order of one micron in diameter and 0.003937 in. (100 microns) in length, are intertwined within the alumina-matrix structure. These whiskers have a tensile strength of about 1 million psi and dramatically improve the fracture toughness of the tool material. They also effectively block and prevent propagation of cracks. Reinforced ceramics work differently from other cutting materials. With reinforced ceramic cutting tools, the objective in machining is to generate high temperatures ahead of the cutting tool to soften or plasticize the workpiece material. That facilitates the removal of material and a reduction in cutting forces. The ideal cutting temperature in nickel alloy is about 1,800 degrees F, for example. Cutting with ceramic inserts requires high surface speed and balanced feedrates. High speed is necessary to generate the high temperature in the shear zone and to ensure that the heat propagates into the chip-forming zone immediately ahead of the cutter. When cutting speeds are too slow, insufficient heat is generated to soften the material in this zone, and the cutting forces are raised and insert failure occurs. A strategy for using ceramic inserts is to program fewer, but deeper cuts that bury the insert deep in the workpiece. This moves the notch formation further up the face of the insert to an area that has a larger, stronger cross section. Ramping cuts should be programmed to accommodate these tools and fixed depths of cut should be avoided to spread wear over a larger section of the insert. When machining interrupted cuts with reinforced ceramics, it is important to keep the speed of the cutter high. A rule of thumb is to estimate the percentage of voids in the workpiece surface and increase cutting speed by that percentage. This increase in surface speed offsets the loss of heat generation created by the voids. Whiskered ceramics work best on hard ferrous materials and difficult-to-machine nickel-base alloys, including Inconel, Waspoloy and Hastelloy. They do not work well on ferrous alloys below Rc 42 hardness because of the chemical reaction that occurs between iron and the carbon that is part of the silicon carbide reinforcing material. Silicon nitridesCeramics based on silicon nitride offer increased resistance to abrasion and thermal shock and have high fracture toughness. These ceramic tools have a needle-like structure that is embedded in a temperature-resistant grain-boundary. These structures enhance crack deflection, crack bridging and pull-out effects, and lead to superior fracture toughness. These materials are based on compositions of ceramic powders with high purity. Techniques used to produce these ceramics, including optimized powder processing and gas-sintering, enhance their fracture toughness and high-temperature hardness. Silicon nitrides are well suited for rough machining cast iron, even under unfavorable conditions such as heavily interrupted cuts and varying depths of cut. Silicon nitrides also are used to mill cast iron, even with positive tool geometries. Silicon nitrides are suitable for milling operations that produce chips with large cross sections and require positive tool geometries. When used with powerful machine tools, silicon nitrides enable high cutting speeds (more than 800 in./min.) and feeds (0.2 to 0.3 in./min.) for rough boring cast iron. Silicone nitride tools offer fracture resistance, but their relatively low resistance to chemical wear limits their use in machining nodular cast irons. However, wear-resistant, chemical vapor deposit (CVD) alumina coatings have expanded the range of applications for silicon nitride-based tools to include these difficult-to-machine irons. Gray cast iron and nodular graphite cast iron can be milled at cutting speeds of 500 to 800 in./min or sometimes faster than 1,000 in./min. Five Types of Ceramic Cutting Tools.There are five types os ceramic cutting tools. Here are the basic differences:

ALUMINIUM OXIDE OR WHITE CERAMIC NTK GRADES: HC1, CX3, HW2 Pure alumina strengthened by Zirconium.

MIXED OR BLACK CERAMICS NTK GRADES: HC2, HC4, HC5, ZC4 Alumina with metallic phase of Titanium Carbide and Titanium Nitride which improves thermal conductivity.

SILICON NITRIDE BASED CERAMICS NTK GRADES: SX1, SX2, SX8, SP2

WHISKER REINFORCED CERAMICS NTK GRADES: WA1 Pure alumina structurally strengthens from introduction of Silicon Carbide in the form of whiskers.

SIALONS NTK GRADES: SX5 Alumina substrate strengthened by Silicon Nitride.

The above text is from American Machinist's Cutting Tool Central. For up to the minute information follow them on Twitter @AmericanMachnst |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed