|

The number of flutes on a carbide end mill significantly influences its performance across various machining applications. How many flutes do you need? The simple answer: It depends. Obviously there are a quite a number of other factors that impact an end mills performance such as helix angel, edge prep, gullet depth and radius. We can't tackle everything in this article, but hopefully this helps you get a better understanding of why there are different numbers of flutes on end mills. Below is an overview of the advantages and disadvantages associated with end mills featuring different flute counts, along with recommendations for materials based on ISO 513 categories (P, M, K, N, S, H) Single Flute End Mills

2-Flute End Mills

3-Flute End Mills

4-Flute End Mills

5-Flute End Mills

6-Flute End Mills

7-Flute End Mills

8-Flute End Mills

0-Flute End Mills

Advantages of Higher Flute Counts in |

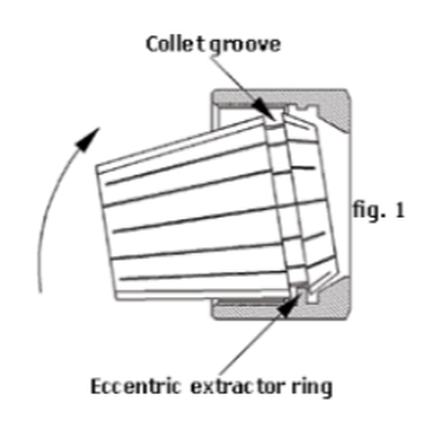

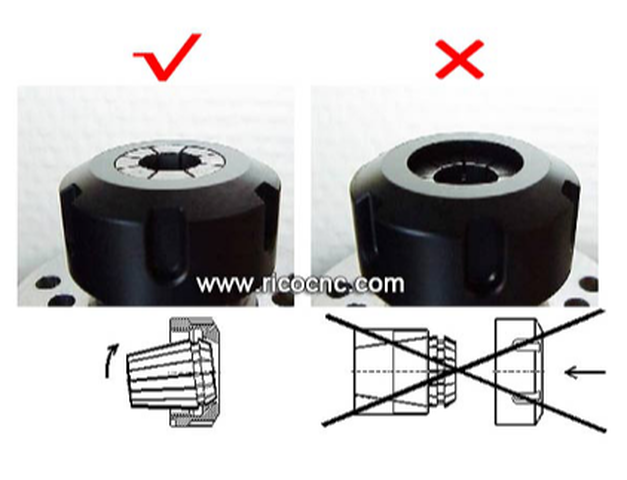

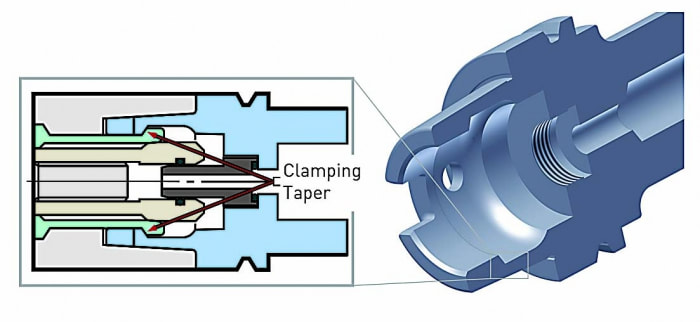

| As the collet nut presses down and turns against the 30° face of the collet, the collet face will tend to twist with the collet nut, distorting the shape of the collet. This radial distortion negatively affects tool run-out sine the collet bore is not longer straight. Parlec’s new P3 ER collets have a special anti-friction coating on the 30° face that dramatically reduces friction at this critical connection. |

- Improved tool runout

- Longer tool-life

- Less frequent tool changes

- Improved surface finishes

Other Parlec P3 collet advantages:

- 3 micron T.I.R

- Fewer slots that standard collets making them more rigid – in the cut!

- Special slotting seal for coolant up to 2,000 PSI

Don’t throw away you ER collet chucks to improve accuracy

Try Parlec P3 collets and supercharge your ER collet system.

Boring Bars

Solid boring bars

Typically made of carbide for finishing or heavy metal for roughing, solid boring bars have dense structures that make for a more stable cut as axial force is applied.

Damping bars

When cutting speeds are compromised, or surface finishes show chatter in a long-reach boring operation, damping bars are an option. They have integrated damping systems. Our version, the Smart Damper, works as both a counter damper and friction damper so that chatter is essentially absorbed.

Boring Heads

Rough boring heads

Once a bore is started with a drill or by another method, rough boring heads are the choice for removing larger amounts of material. They are built more rigid, to handle the increased depths of cut, torque and axial forces needed to efficiently and consistently make the passes to remove materials.

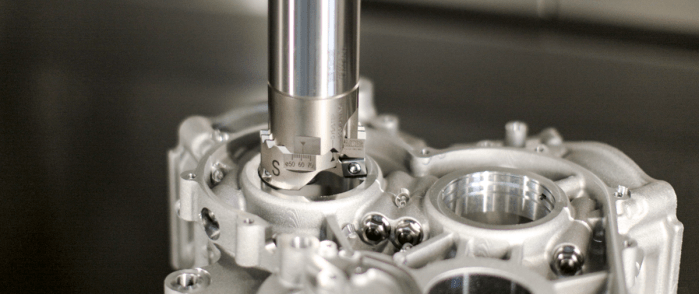

Fine boring heads

Fine boring heads are best used for more delicate and precise removal of material that finishes the work the rough boring head started. They are often balanced for high-speed cutting since that’s the best approach for reaching exact specifications.

Twin cutter boring heads

Most boring heads feature one cutter that cuts as its feed diameter is adjusted by the machine. There are twin cutter boring heads that can speed up cutting and add versatility. For example, the Series 319 and other BIG KAISER twin cutter boring heads include two cutters that can perform balanced or stepped cutting without additional accessories or adjustments by switching the mounting locations of the insert holders that have varied heights.

Digital boring heads

Traditionally, adjusting boring heads has been painstaking and time-consuming, especially when it’s done in the machine. It’s easy to make mistakes when maneuvering to read the diameter dial and adjusting it to the right diameter. Digital boring heads have a LED that makes precise adjustments much easier.

Starter Drills

Specialty boring heads

Back boring and face grooving heads, as well as chamfering insert holders, are available for some of the most common secondary operations, after a hole is bored. We produce specific heads with cutters at the appropriate angles so each of these operations can be done without manually moving the part, changing the tool or adjusting the cutter angle.

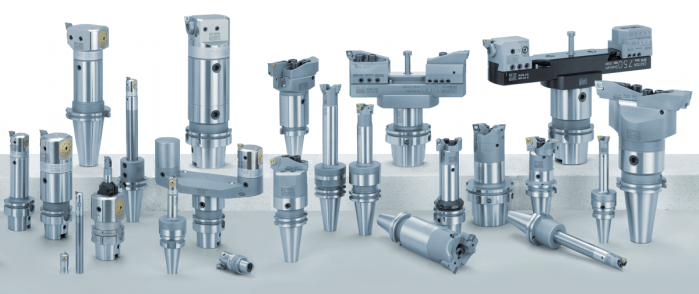

Modular boring tools

Since limiting length-to-diameter ratios is so crucial to boring success, it’s extremely valuable to be able to make your tooling assembly as short as possible. Our modular components are based on a cylindrical connection with radial locking screw that allows for the ideal combination of different kinds of shanks, reductions and extensions, bars, ER collet adapters and coolant inducers.

Looking for some help finding the right boring equipment for your next job or new machine? Our engineers are here to help. Get in touch with us here.

It makes regular inspection and spindle maintenance critical to getting the most out of your equipment and maintain process efficiency. These three accessories, the Dyna Contact Taper Gage, the Dyna Test Bar and the Dyna Force Measurement Tool, can help you perform this maintenance easily without eating into valuable spindle time.

Dyna Contact Taper Gage

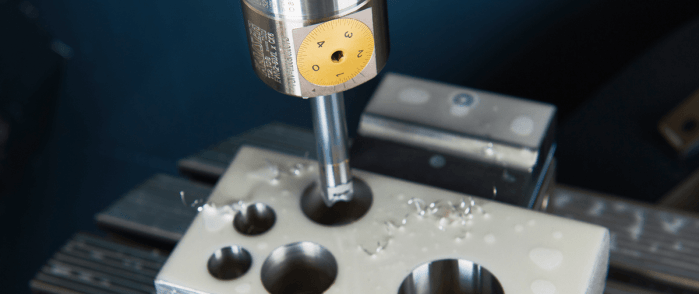

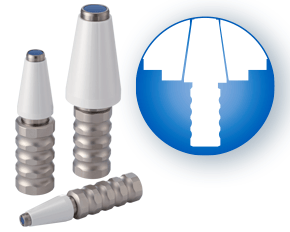

| Spindle taper protection The Dyna Contact taper gage makes verifying taper accuracy simple. All the operator must do is apply blue dye to the ceramic gage, insert it in the machine spindle and remove it. A quick visual check will reveal any improper contact points inside the taper. |

Dyna Test Bar

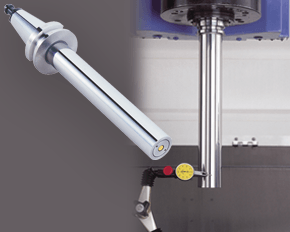

| Static accuracy inspection Another way to ensure your spindle bearings are good and ensure quality control is to measure its static accuracy. Using something like our Dyna Test bar, which inserts into the taper and extends out, is one way to do this. |

Dyna Force Measurement Tool

| Retention force verification Finally, in the machinery category, let’s talk retention force. The clamping mechanism in your spindle reduces chatter while ensuring rigidity and reliability. Like any other mechanism this can wear, making regular inspection a smart idea. |

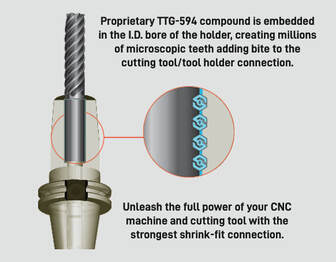

Shrink fit holders are the most accurate for TIR as the toolholder engages completely around round shank tools with a bore tolerance of -0.0001" to -0.0003". As high performance end mills have tightened shank tolerances to the same range of -0.0001" to -0.0003" they have used finer and finer grain grinding wheels which give the shanks a 'shiny' appearance.

Shiny means that the superfinished shank has a lower coefficient of friction. So, although the TIR is tighter, the shank is more "slippery". End mills traditionally had surface finish of about 8 μin on the tool shank. But that's changed. It's been recommended that tool shanks used in shrink fit holders should not have a finish finer than 16 μin. for optimum holding power, but tell that to the guy who just superfinished the end mill to a super cocncentric tolerance that you don't want it looking that good.

Everyone knows that the last thing you want is for the end mill to slip in the middle of a heavy cut or on the finishing pass of a high tolerance part. These 'hi performance' end mills, often times have higher helix angles which are great for ejecting chips but also create a higher pull out force on that slippery shank. And reducing the helix angle is not the answer.

We already know that the gripping pressure is a function of the interference between the tool shank and the shrink fit toolholder bore. Most shrink fit holders have a already bore surface finish of between 12 μin. and 16 μin. So they are ground to a very high tolerance and have about the same surface finish as the toolholder shank.

End mill manufacturers and machinist have tried a variety of methods over the years to stop the tools from pulling out. This has ranged from grit blasting the shank to rubbing chalk on the shank, but most everyone in the industry has felt that the problem really needs to be addressed by the longer life toolholder rather than the replaceable cutting tool.

That's the problem that Techniks wanted to address. Techniks claims that their "proprietary non-slip TTG594 compound virtually fuses the tool shank with the shrink fit toolholder."

ShrinkLOCKED Toolholders eliminate cutting tool pull-out and provide 4X the friction drive force compared to un-treated shrink holders.

Techniks arrived at their 4x the holding power comes from torsion testing vs. a standard shrink fit toolholder. They used a ¾” carbide gage pin in a standard holder and found the torque at which the tool will spin in the bore.

They then tested the ShrinkLOCKED holder using the same test.

According to Greg Webb, at Techniks,

"We actually could not find the point at which the tool would spin in the ShrinkLOCKED holder as we broke the carbide gage pins at 4x+ times the torque of the standard holder. The holding power is greater, we just have not found a way to measure this, so we kept our claims conservative at 4x."

If you understand why a long tool holder behaves the way it does, you’ll know that there are ways to fight back against this bending. Every machinist knows that short and stubby holders are more resistant to deflection than long and slender holders. You’ve also probably heard that, if possible, you’ll want most of your cutting forces to be axial rather than radial.

Not only does this fight chatter in operations like boring, but your spindle also is better equipped to handle loads in this axis. However, these options aren’t always going to be on the table, especially in unavoidable long-reach situations and many milling operations.

In this constant battle with tool deflection, much time and effort has been spent designing shorter holders, stiffer tools, and clever anti-vibration geometry and materials. But oftentimes, the body diameter(s) of the holder can be overlooked as a means of increasing rigidity, especially in situations where it is all you have to work with. This is a serious shame, as you’ll soon discover.

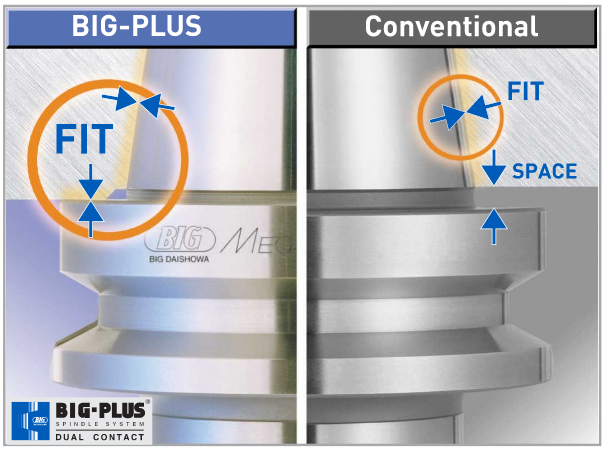

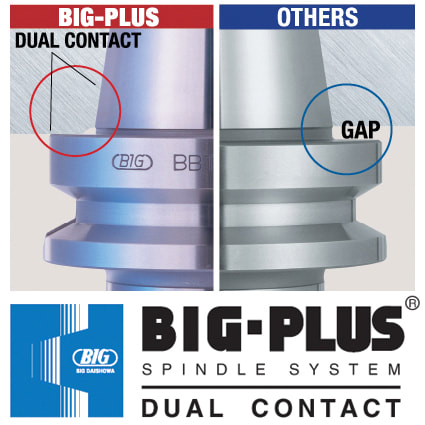

The concept of dual-contact technology has been around for years, existing in many different forms but always with the same goal of capitalizing on this untapped potential of rigidity. For those who don’t know, dual contact refers to the shank contacting the spindle taper and the spindle face simultaneously.

Oftentimes, the solution involved ex post facto alterations to the spindle or tool holder, such as using ground spacers or shims to close the gap, for example. In other words, there was no standard solution, and if you wanted dual contact, you would have to be prepared to spend time and money either buying modified tool holders or modifying them yourself to adapt them to your spindle.

BIG-PLUS emerged as a solution to this issue. Essentially, both the spindle and tool holder were ground to precise specifications so that they closed the gap between spindle face and flange in unison (while depending on very small elastic deformation in the spindle). What this meant is that operators were able to confidently switch BIG-PLUS tooling in and out of a BIG-PLUS spindle and achieve guaranteed dual contact.

Not only that, but standard tooling could still be used in a BIG-PLUS spindle if necessary, and vice versa.

Though not technically an international standard, it’s been adopted by many machine tool builders because of the clear performance improvements and simplicity. In fact, BIG-PLUS spindles come standard on more machines than you would think. We often come across operators that have machines with BIG-PLUS spindles and don’t even realize it.

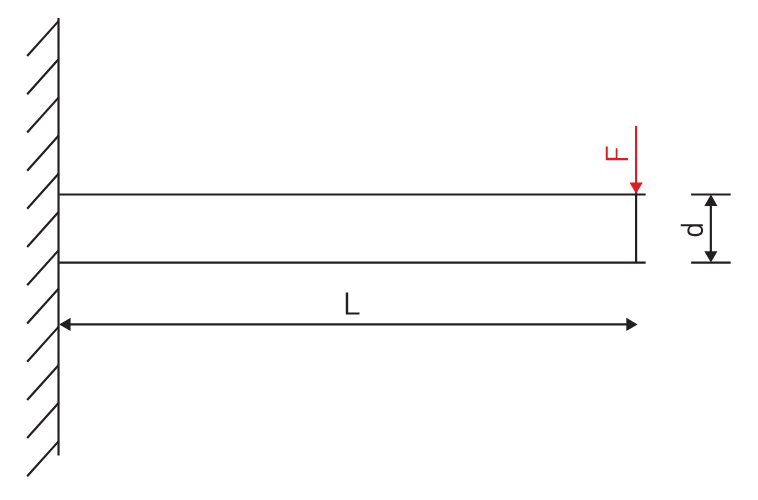

It’s not too much of a leap to conclude that a larger effective diameter will give you more rigidity. That being said, you may still be asking yourself: does such a seemingly small increase in diameter really make a difference? To understand the effect of BIG-PLUS, you must understand the physics behind it.

Imagine a simple scenario in which a tool holder is represented by a cylindrical bar that is fixed at one end and free-floating at the other. In other words, a cantilever beam. If you think about it, this is essentially what a tool holder becomes once it’s secure in the spindle. Now, let’s introduce a radial force F that acts downward at the suspended end of the bar, which represents a cutting force you would encounter when milling or boring, for example. The bar, as you might expect, will want to bend downward. It’s similar to how a diving board bends when someone stands at the end, though less exaggerated.

Something interesting to note is that d is raised to the 4th power, while L is only raised to the 3rd power. Diameter affects rigidity an entire order of magnitude more than the length does. This is where the power of BIG-PLUS comes from and is why a small increase in diameter can have such a powerful effect on performance.

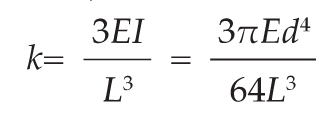

If you were to plug these values into the above equation for comparison, you would find that the BIG-PLUS holder results in a k value that is around 4 times greater than the standard bar. Based on this comparison, you could say that a BIG-PLUS holder is 4 times as rigid as an identical standard CAT40 holder, because it is 4 times as resistant to deflection.

Think of the tool life and surface finish improvements you would see with a tool that is 4 times more rigid, not to mention the reduction in fretting and potential for reduced cycle time. You would get similar results if you were to make the same comparison for CAT50, BT40, BT30, etc.

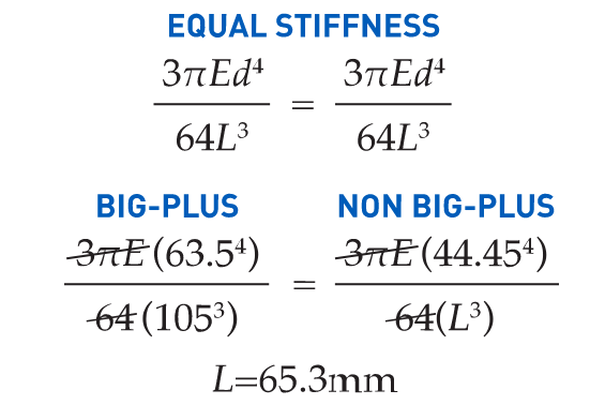

You’re probably wondering, at what length would a comparable standard CAT40 holder have an equal stiffness? If we take our stiffness expression and set it equal to itself (one side representing BIG-PLUS, the other non BIG-PLUS), we can plug in this BIG-PLUS holder length and our known diameters to find our unknown non-BIG PLUS length:

If this is true, we can say that implementing BIG-PLUS is equivalent to a 40% reduction in length in terms of rigidity. Theoretically, a BIG-PLUS tool holder will behave like a standard tool holder that is nearly half of its length!

Obviously, we’ve used simple and idealized cases here to represent the complicated and dynamic world of metal cutting. Tool holders, of course, don’t have uniform body diameters or materials and the cutting forces usually aren’t acting in one direction in a constant and predictable way. If our holder necks up and down to different body diameters along its length, which is realistically what happens, each of these sections would be its own microcosm of “beam” that would influence the overall behavior (at that point, finite element analysis on a computer becomes the only practical way to predict behavior).

So, will the advantage of BIG-PLUS really be as dramatic as our hand-calculated classical beam theory suggests? Probably not, but it depends on the tool holder/tool. Most cases will follow our simple model quite closely in practice; others not so much. If nothing else, we’ve demonstrated how dramatically the flange contact of BIG-PLUS can influence rigidity, at least in a purely mathematical sense.

As if you needed any more reasons to be on the BIG-PLUS bandwagon besides increased rigidity, you will also eliminate Z-axis movement at high speeds, improve ATC repeatability and decrease fretting. This means that you will take heavier cuts, scrap less parts, and increase tool and spindle life.

BIG-PLUS isn’t a new idea by any means, but with a proven track record of tackling tough jobs, it’s hard to imagine working in a modern machine shop and not taking advantage of what it has to offer.

If you’re still not convinced, we can also compare the rigidity in this way: Let’s say there is a Ø63.5 mm BIG-PLUS CAT40 bar of some arbitrary length. One of our more common gage lengths is 105 mm, or just over 4 inches, so let’s use it as an example.

You’re probably wondering, at what length would a comparable standard CAT40 holder have an equal stiffness? If we take our stiffness expression and set it equal to itself (one side representing BIG-PLUS, the other non BIG-PLUS), we can plug in this BIG-PLUS holder length and our known diameters to find our unknown non-BIG PLUS length:

(520) 548-7328

[email protected]

Kip Hanson is a contributing editor for Cutting Tool Engineering magazine. Originally Published: September 12, 2017 - 3:00pm

With the development of automatic toolchangers in the late 1960s, machine tool builders in Japan modified the patented design and invented the BT standard. In the 1970s, tractor manufacturer Caterpillar Inc., Peoria, Ill., changed things again with a flange design now known as CAT, or V-flange.

“Sticking” Together

Chief among them is the tendency for the mating spindle and toolholder tapers to stick together. This is caused by the expansion of the spindle housing at high speeds, which allows the toolholder to be pulled upward into the spindle taper, jamming it in place.

One way to eliminate this problem is by extending the toolholder flange upward, thus creating a hard stop against the spindle face and preventing further Z-axis movement.

He said it’s also more rigid, with tests showing that the deflection on a CV40 BIG-PLUS toolholder measured at 70mm (2.755") from the spindle face is only 60µm (0.002") when subjected to 500kg (1,102 lbs.) of radial force, roughly half that of a traditional V-flange toolholder.

Revving Up

BIG-PLUS, like any dual-contact toolholder, requires particular attention to cleanliness, as chips caught between the spindle face and the toolholder can cause serious problems.

He also recommends staying below 30,000 rpm when using 40-taper holders, noting that higher speeds are better handled by HSK spindles and holders.

Keep It Clean

These requirements were impossible to meet when steep taper was first developed, Popoli said, resulting in looser standards overall for CAT and BT spindles than the ones applied to HSK spindles and toolholders. Because of this, purchasing an HSK or equivalent toolholder automatically makes one “part of the club” when it comes to balance, accuracy, repeatability and tool life.

Always stay below 20,000 rpm with 40-taper holders, and reach no more than 30,000 rpm with 30-taper ones. Use balanced holders and high-quality retention knobs that have been properly torqued—otherwise distortion at the small end of the taper may occur. And whatever the taper type, keep the spindle and toolholder clean at all times.

Bob Freitag agreed. The manager of application engineering at Minneapolis-based metalworking products and services provider Productivity Inc. said the lines are evenly split between traditional 40- and 50-taper CAT or BT tooling (much of which is BIG-PLUS) and HSK.

“It really depends on the application,” Freitag said. “Most of our die and mold machines in the 20,000- to 30,000-rpm range will have an HSK63A or HSK63F. When you get up around 45,000 rpm, you’re probably looking at an HSK32. But in horizontal machining centers and lower-rpm, high-torque verticals, you’ll see mostly steep tapers, as this is generally preferred for deep depths of cut and lower feed rates, where you’re removing a lot of material at once.”

For shops that want to make the leap to an HSK machine but are leery of investing in new toolholders, Freitag advised:

“Anytime you buy a new machine, you should buy new toolholders to go with it. If not, the imperfections of the old toolholders will soon transfer themselves to the spindle on the new machine.”

Technical Support Blog

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference.

If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website.

Authorship

Our technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada.

Archives

July 2024

June 2024

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

December 2022

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

February 2022

December 2021

November 2021

October 2021

September 2021

August 2021

July 2021

June 2021

May 2021

April 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

August 2020

July 2020

June 2020

May 2020

March 2020

February 2020

January 2020

September 2019

August 2019

July 2019

June 2019

May 2019

March 2019

January 2019

September 2018

June 2018

April 2018

February 2018

December 2017

November 2017

October 2017

August 2017

June 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

August 2016

March 2016

February 2016

January 2016

November 2015

August 2015

July 2015

May 2015

April 2015

March 2015

November 2014

August 2014

July 2014

December 2013

November 2013

September 2013

July 2013

March 2013

December 2012

March 2012

November 2011

May 2011

March 2011

January 2011

December 2010

November 2010

October 2010

Categories

All

5th Axis

Aerospace

Allied Machine

Aluminum Oxide

Angle Head

AT3

Balance

Bellmouthed Hole

Big Daishowa

Big EWA Automatic Boring

Big Kaiser

BIG Plus

Blue Photon

Bone Screws

Boring Tool

Carbide

Carmex Precision

CBN

Centerline Deviation

Ceramic Black

Ceramic End Mill

Ceramic Inserts

Ceramic Oxide

Ceramic Whiskered

Ceramic White

Chamfer

Champion Tool Storage

Chip Breaking

Circular Saw

Class Of Fit

CNC Lathe Tooling

Collet

Collet Chuck

Collet ER

Collet TG

Composites

Covid-19

Deep Hole Boring

Deep Hole Drilling

Drilling

Dual Contact

Dyna Contact Gage

Dyna Force Tool

Dyna Test Bar

EMO

End Mill

Exotap

Facemill

Fixturing

Fretting

Gaylee Saw

Hard Turning

Heimatec

Helical Interpolation

Hohl Shaft Kegel

How Its Made

HSK A

HSK-A

HSK E

HSK-E

HSK F

HSK-F

HXL Tap

Hy Pro Tap

Hy-Pro Tap

IMTS

Jergens

Jergens OK-Vise

Kurt

Lang

Live Tooling

MA Ford

Maintenance Cart

Mapal

Martindale Saw

Material: Aluminum

Material: CFRP

Material: D2

Material: Hastelloy

Material: Inconel

Material: Peek

Material: Stone

Material Titanium

Material: VC 10

Material: VC-10

Metric Course Thread

Metric Fine Thread

Metric Thread Chart

Microconic

Micromachining

ModLoc

Modular

Mogul Bars

MPower

NextGen Tooling

No Go Too Loose

NTK

NTK HX5

On Site Training

OptiMill-SPM

OSG Tap & Die

Oversized Thread

Parlec

PCD

PCT Firm Hold

Platinum Tooling

Projection Length

Pull Studs

Reamer

Retention Knob

Rotary Toolholders

Rotary Toolholders BT

Rotary Toolholders CAT

Rotary Toolholders HSK

Rotary Toolholders Hydraulic

Rotary Toolholders Shrink

Rough Thread

Runout

Runout Axial

Runout Radial

Safe-Flex

Saw Selection

Short Tap Life

Sialons

Silicon Nitride

Smart Damper

Speed Increaser

SpeedLoc

Speroni STP Essntia

Spindle Mouth Wear

Surface Roughness Ra

Surface Roughness RMS

Swiss

Swiss Machining

Taper Wear

Tapping Feed

Tapping; Form

Tapping IPM

Tapping: Roll

Tapping RPM

Tapping Speed

Tap Tolerance

Technical Training

Technicrafts

Techniks USA

Thread Milling

Thread Whirling

T.I.R.

Tolerance

Toolchanger Alignment

Toolholder Taper

Tool Presetter

Torn Thread

Troubleshooting

UNC Thread Size

Undersized Thread

UNF Thread Size

Unilock

Vises

Washdown Tool

Workholding

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed