BIG Daishowa

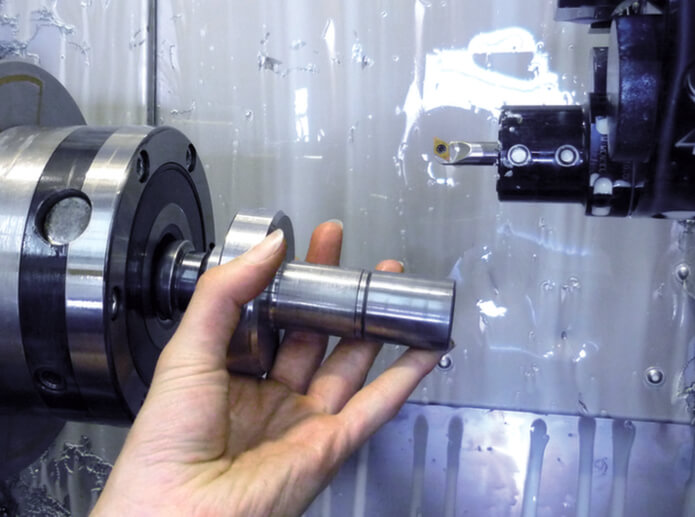

Since 2000 we've represented BIG DAISHOWA. in Northern California and Northern Nevada. They are a worldwide leader in the development and manufacture of precision boring tools and modular #CNC boring systems of unmatched quality based in Hoffman Estates, IL.

BIG KAISER Precision Tooling Inc., was originally established as the U.S. subsidiary of Heinz Kaiser AG, Rümlang, Switzerland in the spring of 1990. In January 2022, BIG KAISER Precision Tooling Inc became BIG DAISHOWA

BIG KAISER Precision Tooling Inc., was originally established as the U.S. subsidiary of Heinz Kaiser AG, Rümlang, Switzerland in the spring of 1990. In January 2022, BIG KAISER Precision Tooling Inc became BIG DAISHOWA

BIG Daishowa2600 Huntington Blvd

Hoffman Estates, IL 60192 Toll Free: 888-866-5776 Phone: 224.770.2999 Fax: 224.770.2997 [email protected] |

BIG Daishowa Seiki, is one of the world’s leading producers of precision tool holders and measuring accessories, it operates four manufacturing facilities in Japan, one in Osaka and three in Awaji. The company was established in 1967 and now employs more than 500.

Heinz Kaiser AG (HKAG) celebrated its 66th anniversary in 2014, and is Europe's leading producer of precision boring tools and modular tool systems. HKAG and its subsidiaries serve manufacturing communities in the global market of more than 30 countries.

Heinz Kaiser AG (HKAG) celebrated its 66th anniversary in 2014, and is Europe's leading producer of precision boring tools and modular tool systems. HKAG and its subsidiaries serve manufacturing communities in the global market of more than 30 countries.

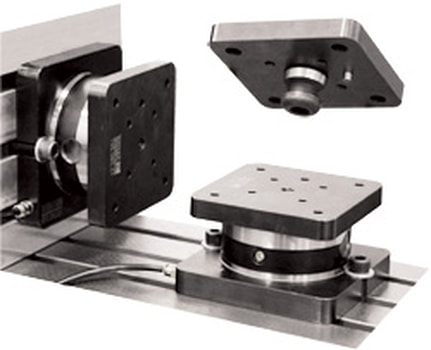

Unilock Modular Workholding

|

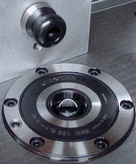

The quick change Unilock zero point clamping chuck system can reduce machine set up time by up to 90% while increasing accuracy and repeatability to greatly improve your overall efficiency.

The UNILOCK system is easily adapted to existing pallets, fixtures and workpieces. Clamping chucks on every machine tool increases quality and throughput with repeatability of 0.0002" or better with quick, accurate changeovers. |

|

Each UNILOCK chuck was developed for a specific application, to be used efficiently for different requirements.

Our many years of experience in zero-point clamping and our enthusiasm for clamping technology in general, are visible in our products. The UNILOCK family was designed compatible since its beginning and was always developed further as a system. |

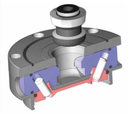

The powerful, stable UNILOCK Clamping knob is the central element of this product range and has evolved over the years to become a standard in the zero-point clamping technology.

UNILOCK is a media-free, self-locking clamping system with a very high power absorbing contact area ratio. The conical pull-down of the short cone is self-centering and supports an easy moving-in. A play-free, power-closed centering as well as a repeatability of <0.003mm by use under perfect conditions is charactarizing this Zero-point clamping system.

A big advantage in comparison with various competition products are the perfect form-locking and a retention force of 50'000N (static) by fixation with an M12 Clamping screw.

In addition to all actual Clamping chucks our development department also creates your special clamping- or device solution.

UNILOCK is a media-free, self-locking clamping system with a very high power absorbing contact area ratio. The conical pull-down of the short cone is self-centering and supports an easy moving-in. A play-free, power-closed centering as well as a repeatability of <0.003mm by use under perfect conditions is charactarizing this Zero-point clamping system.

A big advantage in comparison with various competition products are the perfect form-locking and a retention force of 50'000N (static) by fixation with an M12 Clamping screw.

In addition to all actual Clamping chucks our development department also creates your special clamping- or device solution.

Check out the latest BLOGs on

Big Daishowa's Products

Flexible 5-Axis Workholding Solutions Keep Spindles Running

"The benefits of 5-axis machines are greatest when workholding is based on the size and shape of the workpiece instead of the limitations of the table interface. By providing multiple workholding opportunities, Unilock users quickly integrate most workholding products and keep their machine spindles up and running."

"The benefits of 5-axis machines are greatest when workholding is based on the size and shape of the workpiece instead of the limitations of the table interface. By providing multiple workholding opportunities, Unilock users quickly integrate most workholding products and keep their machine spindles up and running."

Unilock workholding for lean manufacturing

"To be competitive in today's market, all machines need efficient workpiece handling.

Efficient part loading systems are always included in the acquisition of high-volume manufacturing cells but all too often getting fixtures on and off the CNC milling machine is forgotten. In today's market, time is money."

"To be competitive in today's market, all machines need efficient workpiece handling.

Efficient part loading systems are always included in the acquisition of high-volume manufacturing cells but all too often getting fixtures on and off the CNC milling machine is forgotten. In today's market, time is money."

The UNILOCK modular workholding system: A real time saver in cycle time

"Have you seen the Big Kaiser UniLock? It's a great modular workholding system for quick changeover and quick location. We're finding that alot of our customers who are using it are telling us that it's been a real time saver for workpiece set-up and changeover especially in the short delivery small lot size repeat jobs."

"Have you seen the Big Kaiser UniLock? It's a great modular workholding system for quick changeover and quick location. We're finding that alot of our customers who are using it are telling us that it's been a real time saver for workpiece set-up and changeover especially in the short delivery small lot size repeat jobs."

|

Your browser does not support viewing this document. Click here to download the document.

|

accuracy amp big-plus boring capto chucks cnc collet contact cutting design drills finish flexible greatly heads holders increase kaiser life line machine magis manufacturers measuring mega milling modular offers operations performance precision presetting products provide quality reduce rigidity size speed speroni spindle system tapping tool toolholders unilock workholding workpiece world

created at TagCrowd.com

last edit 11 Jan 2024

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|