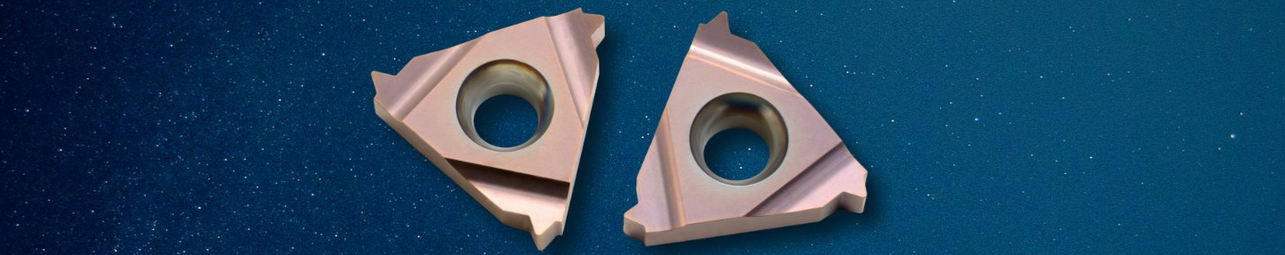

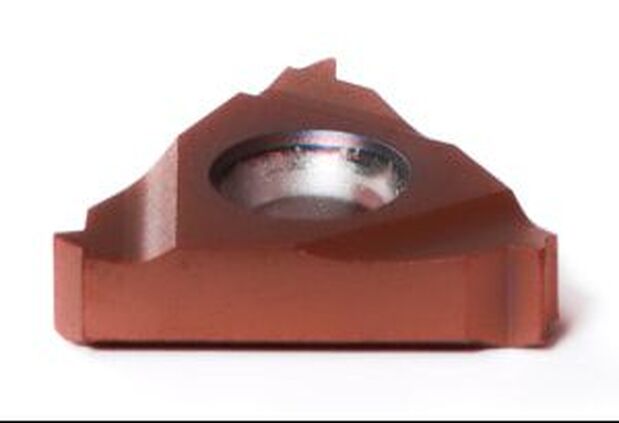

Tough, Precise, and Fast —Carmex HBA carbide grade is available today for tomorrow’s materials10/21/2020 As more applications require the use of super-hard alloys, manufacturers are demanding tooling that can deliver precision threads and high production in less time. To meet these challenges, Carmex Precision Tools Ltd. has engineered carbide grade HBA — an extra-fine, submicron grade with high toughness for optimized performance on hardened steel Titanium and super alloys including Hastelloy, Inconel and Nickel base alloys up to 62 HRc. Available for internal and external threading in both 60° and 55° partial profile, as well as ISO metric and UN, HBA delivers high wear and heat resistance and excellent edge stability. The unique combination of carbide substrate, coating type and edge conditions provide superior performance over extended tool life. Case Study in Threading D2 at 53-56HRc In a recent test involving an external right-hand thread:

Hard machining is increasingly becoming the rule rather than the exception in complex part production. Carmex HBA was engineered to meet the challenges inherent in threading hard materials while delivering high production and longer tool life. Bring us your most challenging hard threading applications and lets try the new Carmex HBA engineered performance carbide .

0 Comments

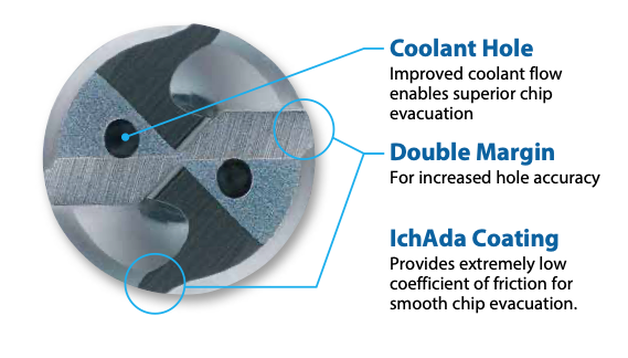

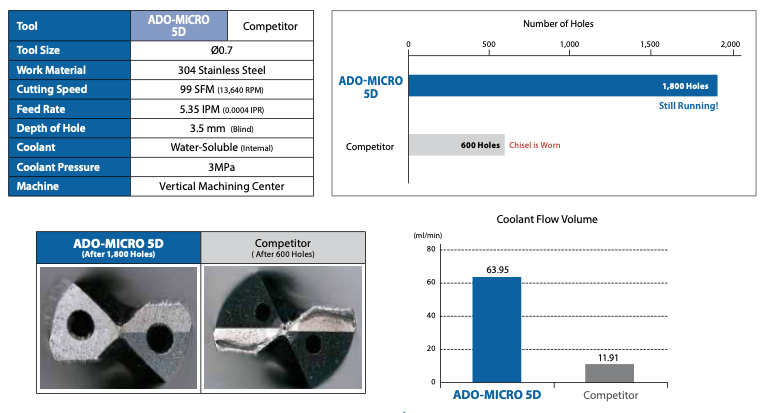

Small Diameter Coolant-Through Carbide Drills 2D · 5D · 12D · 20D · 30D OSG Corporation has announced the release of the ADO-MICRO small diameter coolant-through carbide drill series for stable and high efficiency drilling in small diameter deep-hole applications. Poor chip evacuation is a common complication in small diameter deep-hole drilling. Micro sludges can be easily accumulated around the outer periphery of the cutting tool, which is a key cause of abrupt tool breakage. The ADO-MICRO features a unique double margin geometry with an extended flute and shortened end margin to enhance chip evacuation capability. In addition to the outstanding chip ejection performance, the double margin configuration supports the straightness stability of the tool and reduces rifle marks on the inner surface of holes. Furthermore, the ADO-MICRO features a pair of large oil holes and employs a hollow shank design to allow large coolant flow volume for trouble-free chip evacuation. The ADO-MICRO is coated with OSG’s original IchAda coating that provides excellent surface smoothness in conjunction with high abrasion resistance and heat resistance to enable small diameter tools to achieve long tool life. With the ADO-MICRO’s unique tool geometry and IchAda coating, non-step drilling is made possible even for deep-hole applications, enabling high processing efficiency. The ADO-MICRO is suitable for carbon steel, alloy steel, stainless steel, cast iron, ductile cast iron, aluminum alloy, titanium alloy and heat resistant alloy. The ADO-MICRO is available from diameter 0.7 mm up to 2 mm for drill lengths 2xD and 5xD, and diameter 1 mm to 2 mm for drill lengths 12xD, 20xD and 30xD. Got an application you want to try this on? Give us a call! |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed