|

Looking for the perfect 5-Axis Self-Centering vise to the test against a leading competitor's vise. We've rigorously evaluated both vises across four critical performance categories to help you make an informed choice for your workholding solution. Test Categories:

Discover the results and decide which vise is your ideal companion for all your projects. At Jergens, we're committed to providing top-quality manufacturing solutions, and we believe in transparency. Our goal is to help you make an informed decision when it comes to your tools, and this video is just one example of that commitment. Don't forget to like, share, and subscribe for more informative content about our products and manufacturing innovations. Have questions or suggestions for future comparisons? 00:00 - 00:05 Introduction

00:06 - 00:11 Video Outline 00:12 - 00:26 Jergens Jaw Lift 00:27 - 00:44 Competitor Jaw Lift 00:45 - 00:50 JAW LIFT RESULTS 00:51 - 01:23 Jergens Jaw Repeatability 01:24 - 01:54 Competitor Jaw Repeatability 01:55 - 01:59 JAW REPEATABILITY RESULTS 02:00 - 02:23 Jergens Jaw Changeover 02:24 - 02:42 Competitor Jaw Changeover 02:43 - 02:48 JAW CHANGEOVER RESULTS 02:49 - 03:21 Jergens Jaw Recentering 03:22 - 03:51 Competitor Jaw Recentering 03:52 - 03:56 JAW RECENTERING RESULTS 03:57 - 04:13 Outro

0 Comments

When it comes to broad capability, there are a few clear machine tool choices that production units and shops consider most – Five-axis, Vertical and Horizontal Machining Centers. The criterion for choosing looks different depending on what seat you sit in – from ownership to management to purchasing and finance – but from the shop floor perspective it’s all about making chips.

Getting the most out of these highly sophisticated machines involves a combination of processes, programming, tooling, workholding and human creativity. Set up between them is very different, too. Workholding on a 5-axis and Vertical Machining Centers is very straight forward – literally – since the spindle points directly to the table. Setting up a Horizontal Machining Center (HMC) requires quite a bit more thought because the spindle points to . . . well nothing, just into the open space within the machining envelope. So, what’s the call for it? Over the years, HMCs have evolved from single station to double, with the use of pallet changers, to pool pallets for multiple setups, and now to even include hydraulics within the pallet to load and clamp on the machine. And the evolution continues. Today’s HMCs have great productivity characteristics including the ability to continue machining in one location while part change can take place in another. Many feature automatic tool changers and automatic pallet changers making them well-suited for uninterrupted, unmanned and continuous machining. Configurations with multi-axis spindles also permit true five axis machining. And thanks to gravity, the chips naturally fall away from the parts. To meet this great potential, requires a review of several workholding issues at the outset. 1. Angle Plate or Tombstone First, let’s get back to the open-air orientation. All machining on an HMC starts with a workholding solution. That’s either going to be an angle plate or tombstone (column) that mounts to the HMC indexing table to provide the position and orientation of the workpiece to the spindle. The choice of this fundamental base is dependent upon the answers to remaining things to consider. 2. The Four Basics As with all machining, all fundamental requirements must be met. Workpieces must be held securely. They must be positioned to allow access to machine all sides (ideally without having to change). Operations have to be repeatable (within tolerance). And the setup has to be designed to be easy for the operator. That includes the ability to clear chips, load, move and other ergonomic factors with the safety of that individual always being priority one. 3. What is your current need? If you’re gearing up for the next run of parts, it’s best to begin with an SOW (Scope Of Work) including everything from what you’re looking to accomplish now, to opportunities for greater productivity, and how to best support operator skill level. 4. What is down the road? On the heels of that, savvy engineers are mindful of future needs. Plan for it now and be ready when the demand arises. This past-the-horizon approach saves time for further utilizing technology such as incorporating robotics and other automation. 5. Opportunities for increased productivity There are two additional productivity boosters available depending on the application. The first is the move from an angle plate to a tooling column for the ability to load a greater number of workpieces for any given setup. This is just a matter of math – a two-sided column essentially doubles that number, three-sided triples, and four-sided quadruples. For every incremental increase, there is a corresponding decrease in overall setup time (or downtime), and conversely an increase in productivity (or uptime). Connections are standard T-slots or grid patterns. The second opportunity is the addition of a quick-change system that allows the entire column to be removed, changed and the next one connected, fully loaded and all in a matter of minutes or even seconds. This quick on and off works when repeatability is high and avoids having to again find zero for every changeover. Finding the sweet spot for your shop’s productivity is very much a human effort, and a matter of choosing the best combination of man and machine. In the case of high producers like HMCs, the goal continues to be loading and changing parts faster than the machine can make them. Jergens has introduced its new Washdown Tool, which provides 360° of spray using coolant flow to wash away chips from exposed surfaces. The in-between-processes tool is programmed inline after a predetermined number of machining cycles. The Washdown Tool provides thorough chip removal from the many exposed surfaces inside the machining area. In turn, this saves time for operators by reducing the time spent cleaning chips from a machine interior, workpiece or workholding setup. The unit uses multiple spray nozzles on its circumference, providing a steady and pressurized stream. Each nozzle can be plugged or opened to create customized spray patterns. Added spindle rotation is said to ensure that coolant reaches virtually everywhere inside the machine. Residing in the tool changer, the Jergens Washdown Tool is deployed periodically at scheduled intervals. This automation shortens cleaning time and supports long machining cycles, even lights out manufacturing periods when no operator is present. Jergens Machine Washdown Tool is a cleaning tool attachment for machine spindles and fits 16mm Weldon holders. The user selects which outlets to open, which controls the pressure and direction of the jets. Moving and rotating the spindle under a constant flow of coolant achieves an excellent and systematic cleaning of the machine interior. Through the optional installation of a pressure gauge, the status of the pump, filter, and entire supply line can be checked. Product Specifications:

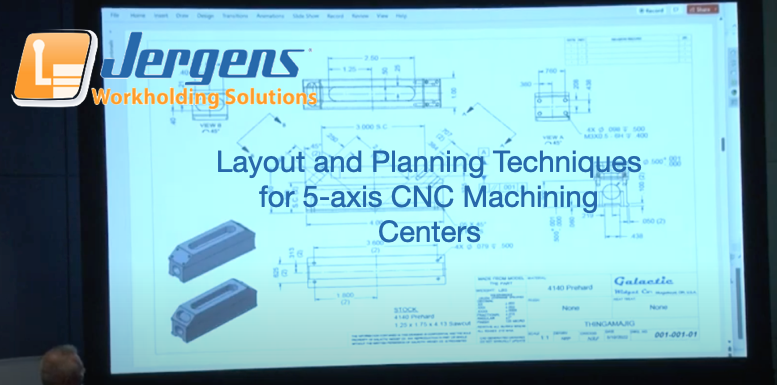

Jack Rushlander, Jergens Technical Sales Manager discusses layout and planning techniques for 5-axis machining centers. Jack talks about how advancements in 5 Axis CNC machining technology has changed dramatically in the past 20 years. Dynamic Work Offsets and other capabilities have made workholding easier but also given shops even more opportunities to to improve process and reduce cycle time. Check out the video below and see how Galactic Widget Company tackles the workholding of a Thingamajig.

Jergen's 5-Axis ER Collet Fixtures Provide Simple Clamping of Cylindrical Parts in a CNC MIll4/12/2022 Looking for a simple and low profile solution for clamping cylindrical workpieces and round bars? Do you ever need to hold a round shank workpiece and machine it in a CNC Mill?

The ER Collet Fixtures provide a simple and low profile solution for clamping cylindrical workpieces using the same technology you are already familiar with in your rotary toolholders.

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed