|

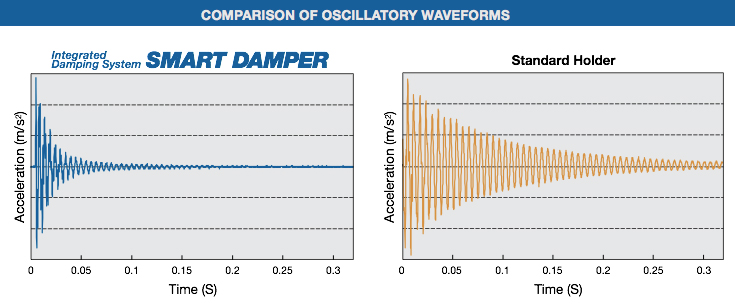

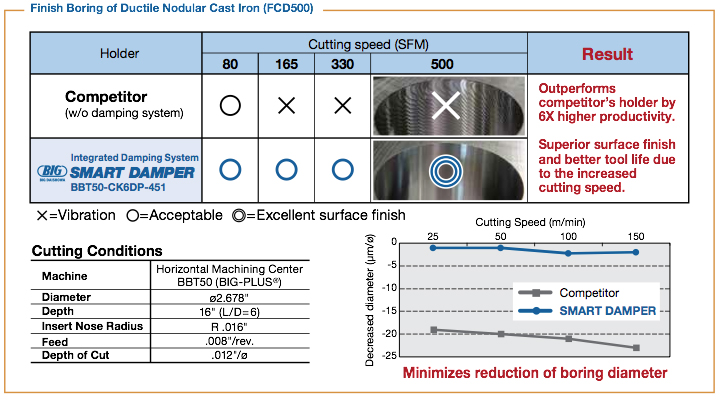

The EWD Smart Damper damps vibrations and reduces chatter in deep-hole finish boring and extended-reach face milling applications – thus achieving better surface finishes and improved metal removal rates. For precision machining of deep bores, it has previously been necessary to choose low cutting data in order to prevent vibrations, which massively increases processing time. The EWD Smart Damper overcomes this problem, and enables high cutting parameters to be used. This means that extremely short turnaround times can be achieved, which improves productivity by up to a factor of ten. Features

Smart Damper products are designed for deep-hole boring with BIG KAISER’s CKB modular boring system, and also for extended reach milling with both inch- and metric-pilot shell mills and face mills. The original rollout of the Smart Damper for finish boring included an integral BCV50, BBT50 and HSK-A100 tool holder with a CKB modular connection at the business end. A BCV50 integral 1” shell mill holder was also available. The next phase of the Smart Damper accounted for more flexibility towards assembling a more custom tool assembly. A modular CKB Smart Damper Extension allowed customers to mount it to any combination of standard CKB shanks, extensions and reductions to create the exact tool configuration for their job. At the same time, a modular thread-on face mill damper head extension was also developed to be used with matching basic holder with different interfaces and gauge lengths. This new design for boring shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration. This produces higher damping effects to the tool assembly to minimize the chatter or vibration – thus achieving better surface finishes and improved metal removal rates.

For more information on Smart Damper Models:

Visitors at the 2015 EMO tradeshow in Milan, Italy, were the first in the world to see our newest solution in the Smart Damper family – EWN and EWD BIG KAISER boring heads with an integral damping system.

If you're just learning about it now you should get in touch with us so we can show you lots of new application solutions!

1 Comment

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed