Since 2000 we've represented Techniks in Northern California and Northern Nevada. They are a leading manufacturer of CNC rotary tooling based in Indianapolis, IN.

TechniksUSA is a manufacturer of: tool holders, collet chucks, ER collet chucks, TG collet chucks, end mill holders, DIN B coolant, coolant-thru holder, tap collets, pull studs, toolholders, milling chucks, jacobs chuck, drill chucks, BT30, BT40, CAT40, CAT50, HSK, ISO30, CNC router tooling, collet holder, aggregate head, shell mill arbors, face mill arbors, shrink fit holders, shrink-fit machines, tap holders, rigid tapping, tap collets, boring tools, finish head, rough head and boring heads.

TechniksUSA is a manufacturer of: tool holders, collet chucks, ER collet chucks, TG collet chucks, end mill holders, DIN B coolant, coolant-thru holder, tap collets, pull studs, toolholders, milling chucks, jacobs chuck, drill chucks, BT30, BT40, CAT40, CAT50, HSK, ISO30, CNC router tooling, collet holder, aggregate head, shell mill arbors, face mill arbors, shrink fit holders, shrink-fit machines, tap holders, rigid tapping, tap collets, boring tools, finish head, rough head and boring heads.

Techniks Inc.

9930 East 56th Street

Indianapolis, IN 46236 Tool Free: 800.597.3921 Tel: 317.803.8000 [email protected] SIMIS ER Collet Chucks

Value-priced ER Chucks offer good performance at a price that won't break the bank.

Features

SIMIS End Mill Holders

If you are looking for quality End Mill holders at an affordable price, give our new SIMIS holders a try.

Features

CoolBLAST Shrink Fit Holders

Features

Standard Milling Chucks

Features

Heavy-Duty Milling Chucks

Features

|

Steel Sealed Coolant Collets

No Seals To Fail – EVER!

Features:

Slim-Fit Modular Tool Holding System

Slim-Fit provides the reach and accuracy you need, PLUS the ability to change tools easily.

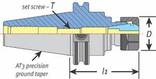

Slim-Fit combines the best features of collet chucks, (fast tool changes and fits a variety of shank sizes) with unmatched rigidity, accuracy, and balance. All in one system. • Collets for fast tool changes • Slim design fits in tight spaces • T.I.R. only 0.0002" • Balanced to 25,000 RPM @ G2.5 CoolBLAST End Mill Holders

Their special coolant-thru end mill holders feature special grooves in the bore that allow coolant to flood the tool and cutting zone.

The additional coolant allows you to increase feed rates and extend tool life. Available for 1/4", 3/8" 1/2", 3/4" and 1" shank sizes. CoolFLEX DIN /Coolant-Thru

|

Check out the latest BLOGS on

Techniks' Products!

Choosing the right ER Collet Chuck Size

"We often get asked to spec out tooling packages for new CNC mills and one of the questions we encounter most, or should, is how do you select the right toolholder collet size for your companies applications? The real choice is in the size of the collet chuck itself. So several considerations should be reviewed…"

"We often get asked to spec out tooling packages for new CNC mills and one of the questions we encounter most, or should, is how do you select the right toolholder collet size for your companies applications? The real choice is in the size of the collet chuck itself. So several considerations should be reviewed…"

Advantages of the ER Collet System

"The ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool. An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA."

"The ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool. An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA."

I like end mills holders, why shouldn't I use them?

"We often run end mill "tests" to determine which one performs best. Obviously, our goal is to "win' the test and get more business for our manufacturer's. This is article is about one our "tricks" and it's also why represent both cutting tool manufacturers and rotary tool manufacturers. We want to insure that the products work together."

"We often run end mill "tests" to determine which one performs best. Obviously, our goal is to "win' the test and get more business for our manufacturer's. This is article is about one our "tricks" and it's also why represent both cutting tool manufacturers and rotary tool manufacturers. We want to insure that the products work together."

Rotary Toolholders: Understanding the problems to watch

"New CNC operators should be taught how to properly evaluate toolholders so they can recognize when toolholders need to be replaced to prevent premature cutting tool failure, or even expensive damage to the spindle. Many operators do not know why it is necessary to replace their tooling, or have the experience to tell when it is time to do so."

"New CNC operators should be taught how to properly evaluate toolholders so they can recognize when toolholders need to be replaced to prevent premature cutting tool failure, or even expensive damage to the spindle. Many operators do not know why it is necessary to replace their tooling, or have the experience to tell when it is time to do so."

Evaluating Toolholders for Wear & Fretting

"A worn out toolholder will not provide good accuracy and will quickly wear out your cutting tools. Worn tooling can also cause poor surface finish, and may even damage your spindle.

Check the taper for signs of wear or damage where it contacts the spindle mouth. Any problems with the taper will have a direct effect on machining accuracy. If there are any imperfections on the taper, the toolholder should not be used. "

"A worn out toolholder will not provide good accuracy and will quickly wear out your cutting tools. Worn tooling can also cause poor surface finish, and may even damage your spindle.

Check the taper for signs of wear or damage where it contacts the spindle mouth. Any problems with the taper will have a direct effect on machining accuracy. If there are any imperfections on the taper, the toolholder should not be used. "

BT, CAT & HSK: What's the important differences for my #CNC?

"HSK is short for the German words "Hohl Shaft Kegel" or, in English, Hollow Shank Taper. There are several major differences between "steep taper" toolholders, like NMTB, CAT & BT and HSK..."

"HSK is short for the German words "Hohl Shaft Kegel" or, in English, Hollow Shank Taper. There are several major differences between "steep taper" toolholders, like NMTB, CAT & BT and HSK..."

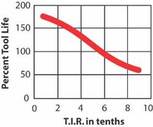

A simple way to improve tool life: Replace the ER's with DNA's

"If you are using carbide drills 1/8" (6mm) and smaller and getting inconsistent tool life, it's more than likely that your collet is the problem. The reason is because standard collets at these drill sizes do not provide consistent T.I.R., so wear is increased. Studies have proven that T.I.R. is a major factor in tool life for small diameter drills, end mills and routers."

"If you are using carbide drills 1/8" (6mm) and smaller and getting inconsistent tool life, it's more than likely that your collet is the problem. The reason is because standard collets at these drill sizes do not provide consistent T.I.R., so wear is increased. Studies have proven that T.I.R. is a major factor in tool life for small diameter drills, end mills and routers."

accuracy balanced bore bt cat chucks cnc collet coolant coolant-thru coolblast cutting drill end er features feed fit head holders holding hsk increase life machines manufacturer maximum mill problems provide rigidity rounded rpm seals several shank simis sizes slim-fit spindle style system tap taper techniks techniksusa tool toolholders used wear

created at TagCrowd.com

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|