|

We are very excited to announce that we are now able to offer on-site technical training to YOUR machinists at YOUR location! This is offered at no charge to customers who use any of the manufacturer's whom we represent in California and Nevada. However, just because you don't purchase things from us, don't feel left out! We also offer on-site topic specter training on any of the following topics for $150/hour. Each presentation lasts about 2 hours. The presentations last approximately 45-60 minutes with the remaining time for Q&A and discussion about unique applications in your facility.  Training Classes Available: Machining 101

Advanced Part Manufacturing:

3 Comments

Next Generation Tooling is excited to offer some new services coming in 2015! Below is a very fast video of our new training series on Tapping which we can present to your manufacturing team at your site. It's a comprehensive overview of screw thread terminology, thread forms, fundamentals of threads, classes of fit, Tap basics, types of chamfers, the tapping process,tap types, screw thread inserts, helix angles, core diameters, re an hook angles, thread reliefs, pitch tolerances, H limits, Tap substrates, Surface treatment and coatings, tapping speeds, tap drill sizes.

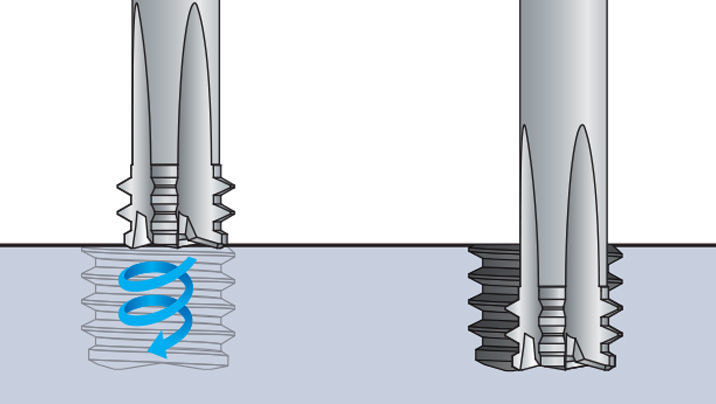

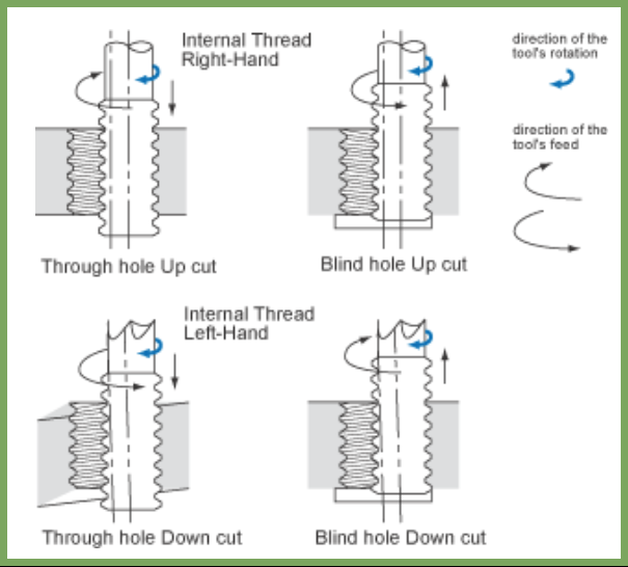

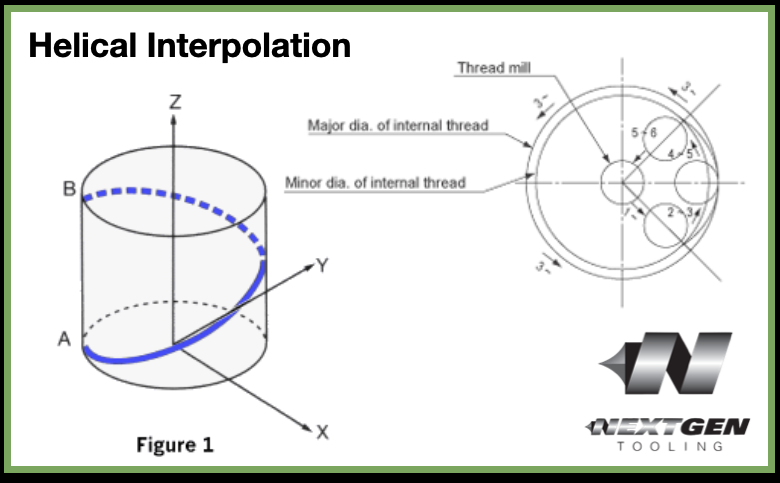

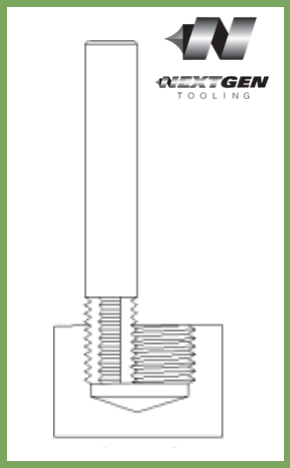

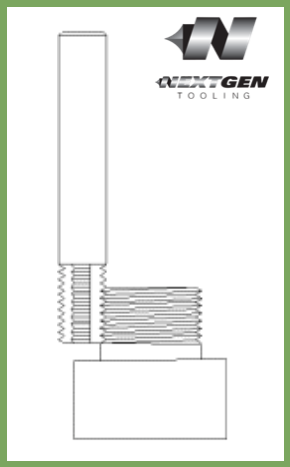

via OSG Tap & Die Jan 2, 2023 editors note: This article has been updated with new drawings and videos since it's original publication date. The machining technique for OSG’s thread mills have been developed for thread milling on a 3-Axis, 4-Axis and 5-Axis CNC controlled machine tool. The thread is processed by advancing one pitch feed per revolution in the axial direction, utilizing the planet-like rotation and revolution movements of the tool. Internal and external thread, right or left hand threads can all be produced with this one tool, simply by changing the direction of rotation and/or feed. This process is called Helical Interpolation and will be explained in greater detail below. Threading Process

The transition between the start and the finish of the milling operation must be smooth, and the appropriate amount of feed is essential for minimizing milling resistance. There are many different methods for using this tool, but our research has shown that this technique provides the most precise and efficient operation. Understanding Thread MillsAny three axis mill that is capable of helical interpolation can be used for thread milling. Helical interpolation involves three axes moving simultaneously. Two axes, 'X' and 'Y', move in a circular motion while the 'Z' axis moves in a linear motion. For example, the path from point A to point B (Figure 1) on the periphery of the cylinder combines a circular movement in the 'X-Y' plane with linear movement along the 'Z' axis. The 'X' and 'Y' circular motion will determine the diameter of the thread. The 'Z' axis linear motion will cut the pitch (or lead) of the thread.

All of the straight flute thread mills are for internal threads only. All of the staggered tooth thread mills will cut both the internal and external threads. The helical thread mills over 0.187 diameter will also cut both internal and external threads. Staggered tooth thread mills have every other tooth removed in a staggered pattern; as the tool rotates the adjacent flute fills in for the tooth that was removed. This helps to reduce side cutting pressure, thus reducing chatter. This can be extremely beneficial in small external sizes and for set-ups that lack rigidity. Helical fluted thread mills are also designed to reduce side cutting pressure by distributing the cutting pressure along a helical flute. Although these tools cost slightly more, their high performance design allows for less chatter and higher feed rates. How to Use Thread MillsTo produce internal threads, drill the minor thread diameter to its appropriate size. Then, position the thread mill to the required depth. Next, mill either the 'X' or 'Y' axis to the required thread pitch diameter. With small sizes and with difficult to cut material, it may be necessary to remove the material in several passes. It is always best to "arc-in" and "arc-out" when thread milling. Any "arc-in" and "arc-out" movements must have a corresponding 'Z'-axis motion during the 'X-Y' circular moves. For example, if the "arc-in" is over 90 degrees, the 'Z'-axis departure must be 1/4 of the thread pitch. (90 degrees is 1/4 of a circle).

The entire process can be achieved by interpolating in a downward direction and reversing the orbit direction. However, it is highly advisable to do so since the tools will have much less material to remove. If the tool is to be interpolated in an upward direction, spiral interpolation must be used. The same surface feet per minute can be used for thread mills as for end mills of the same size. The feed rate must be slower, however, since thread milling often involves unfavorable length-to-diameter ratios. Also, keep in mind that the thread mills have more surface area contact than an end mill of equal length. Most CNC mills are programmed in inches per minute which is applied at the centerline of the spindle. In internal applications, the outside diameter of the tool will be traveling faster than the centerline of the tool. The reverse is true for external applications. It is best to start out conservatively with feed rates and the number of passes required and adjust upward per good machining practice.

Troubleshooting Threadmillingupdate August 2020: OSG just released this new troubleshooting video that further details some thread milling concepts. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

||||||||||

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed