|

The number of flutes on a carbide end mill significantly influences its performance across various machining applications. How many flutes do you need? The simple answer: It depends. Obviously there are a quite a number of other factors that impact an end mills performance such as helix angel, edge prep, gullet depth and radius. We can't tackle everything in this article, but hopefully this helps you get a better understanding of why there are different numbers of flutes on end mills. Below is an overview of the advantages and disadvantages associated with end mills featuring different flute counts, along with recommendations for materials based on ISO 513 categories (P, M, K, N, S, H) Single Flute End Mills

2-Flute End Mills

3-Flute End Mills

4-Flute End Mills

5-Flute End Mills

6-Flute End Mills

7-Flute End Mills

8-Flute End Mills

0-Flute End Mills

Advantages of Higher Flute Counts in |

|

More Designs for Roughing

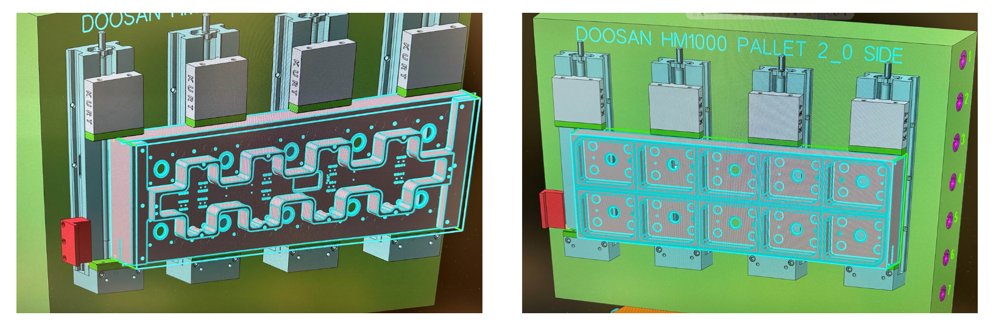

Two new products address additional customer requirements:

- The PCD milling cutter FaceMill-Diamond-ES

- The indexable insert milling cutter NeoMill-T-Finish

Both of these increase economic efficiency in aluminum milling applications.

FaceMill-Diamond-ES – the versatile PCD face milling cutter is ideal for small quantities

| The new FaceMill-Diamond-ES is a versatile addition to the PCD face milling cutters in MAPAL’s FaceMill-Diamond family. While the existing FaceMill-Diamond face milling cutters are established in the high-performance bracket in series production, the FaceMill-Diamond-ES now offers an entry-level version which is economically efficient to procure even for negligibly small quantities and varying parts and meets high standards in terms of surface finish. |

The new milling cutter is available in the diameter range of 32mm(1.26") to 80mm (3.15"). Dimensions have not changed in comparison to existing FaceMill-Diamond models. Accordingly, it can be used directly in existing production, if, for example, the larger chip space of the new tools should be used. Cutting depths of up to 10 mm are easily possible.

All milling cutters in the FaceMill-Diamond-ES series can be reground and re-equipped. They are exclusively available as milling cutters for arbor mounting.

NeoMill-T-Finish – finishing aluminium with indexable inserts

| With the NeoMill-T-Finish, MAPAL presents a milling cutter with indexable inserts for face milling aluminium at high quantities for the first time. The finishing milling cutter with replaceable inserts functions according to the “plug and play” principle: Customers change the inserts on site without having to adjust them afterwards. This means that fewer tool bodies need to be kept on hand as a result. |

The indexable inserts each have up to four usable cutting edges. An optimum version is available for every customer and every requirement, offering maximum economic efficiency and process reliability.

A patent-pending insert arrangement system is what makes the new milling cutter unique. The main inserts, which perform stock removal of up to 2.5mm (0.98"), are attached to the circumference. A wide finishing insert arranged axially is responsible for the ability to reach surface roughness levels of Rz = 1.5 µm.

The innovative system enables homogeneous wear and tear on the cutting edges: Thanks to the special arrangement of main inserts and wide finishing inserts, all main inserts have the same feed per tooth, smooth running for good surface quality and no burr formation.

The resulting longer tool life is reflected in a lower cost per part with a high level of process reliability.

Each tool is adapted specifically to the customer’s requirements. Maximum economic efficiency and productivity are the top priority. The tool body is usually made from steel. If weight restrictions are in place, MAPAL manufactures the tool body in aluminum or with a weight reduction bore.

The NeoMill-T-Finish can be configured in the diameter range from 50mm (1.97") to 315mm (12.4") and can be ordered as a monolithic unit or an adaptive unit for milling holders with arbor.

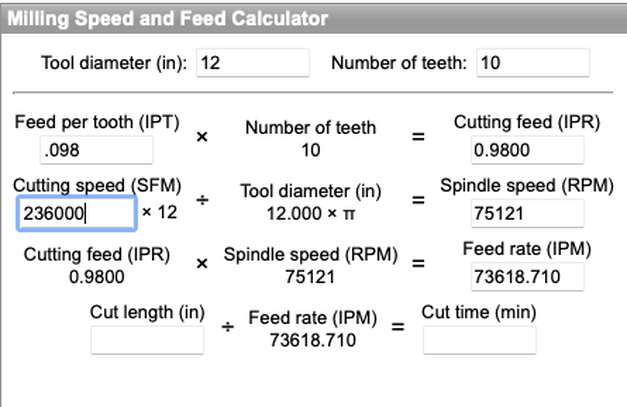

Cutting speeds of up to 6,000m/min (236,220IPM) and feed rates of 2.5mm (0.98" IPR) per revolution are possible in use.

Technical Support Blog

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference.

If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website.

Authorship

Our technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada.

Archives

July 2024

June 2024

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

December 2022

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

February 2022

December 2021

November 2021

October 2021

September 2021

August 2021

July 2021

June 2021

May 2021

April 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

August 2020

July 2020

June 2020

May 2020

March 2020

February 2020

January 2020

September 2019

August 2019

July 2019

June 2019

May 2019

March 2019

January 2019

September 2018

June 2018

April 2018

February 2018

December 2017

November 2017

October 2017

August 2017

June 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

August 2016

March 2016

February 2016

January 2016

November 2015

August 2015

July 2015

May 2015

April 2015

March 2015

November 2014

August 2014

July 2014

December 2013

November 2013

September 2013

July 2013

March 2013

December 2012

March 2012

November 2011

May 2011

March 2011

January 2011

December 2010

November 2010

October 2010

Categories

All

5th Axis

Aerospace

Allied Machine

Aluminum Oxide

Angle Head

AT3

Balance

Bellmouthed Hole

Big Daishowa

Big EWA Automatic Boring

Big Kaiser

BIG Plus

Blue Photon

Bone Screws

Boring Tool

Carbide

Carmex Precision

CBN

Centerline Deviation

Ceramic Black

Ceramic End Mill

Ceramic Inserts

Ceramic Oxide

Ceramic Whiskered

Ceramic White

Chamfer

Champion Tool Storage

Chip Breaking

Circular Saw

Class Of Fit

CNC Lathe Tooling

Collet

Collet Chuck

Collet ER

Collet TG

Composites

Covid-19

Deep Hole Boring

Deep Hole Drilling

Drilling

Dual Contact

Dyna Contact Gage

Dyna Force Tool

Dyna Test Bar

EMO

End Mill

Exotap

Facemill

Fixturing

Fretting

Gaylee Saw

Hard Turning

Heimatec

Helical Interpolation

Hohl Shaft Kegel

How Its Made

HSK A

HSK-A

HSK E

HSK-E

HSK F

HSK-F

HXL Tap

Hy Pro Tap

Hy-Pro Tap

IMTS

Jergens

Jergens OK-Vise

Kurt

Lang

Live Tooling

MA Ford

Maintenance Cart

Mapal

Martindale Saw

Material: Aluminum

Material: CFRP

Material: D2

Material: Hastelloy

Material: Inconel

Material: Peek

Material: Stone

Material Titanium

Material: VC 10

Material: VC-10

Metric Course Thread

Metric Fine Thread

Metric Thread Chart

Microconic

Micromachining

ModLoc

Modular

Mogul Bars

MPower

NextGen Tooling

No Go Too Loose

NTK

NTK HX5

On Site Training

OptiMill-SPM

OSG Tap & Die

Oversized Thread

Parlec

PCD

PCT Firm Hold

Platinum Tooling

Projection Length

Pull Studs

Reamer

Retention Knob

Rotary Toolholders

Rotary Toolholders BT

Rotary Toolholders CAT

Rotary Toolholders HSK

Rotary Toolholders Hydraulic

Rotary Toolholders Shrink

Rough Thread

Runout

Runout Axial

Runout Radial

Safe-Flex

Saw Selection

Short Tap Life

Sialons

Silicon Nitride

Smart Damper

Speed Increaser

SpeedLoc

Speroni STP Essntia

Spindle Mouth Wear

Surface Roughness Ra

Surface Roughness RMS

Swiss

Swiss Machining

Taper Wear

Tapping Feed

Tapping; Form

Tapping IPM

Tapping: Roll

Tapping RPM

Tapping Speed

Tap Tolerance

Technical Training

Technicrafts

Techniks USA

Thread Milling

Thread Whirling

T.I.R.

Tolerance

Toolchanger Alignment

Toolholder Taper

Tool Presetter

Torn Thread

Troubleshooting

UNC Thread Size

Undersized Thread

UNF Thread Size

Unilock

Vises

Washdown Tool

Workholding

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed