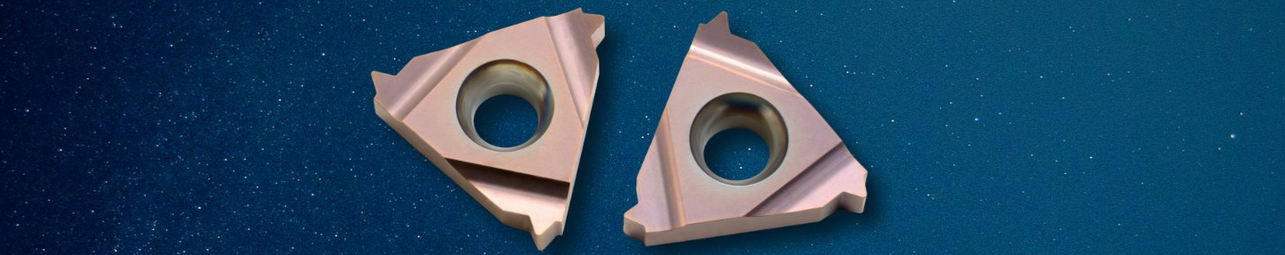

Tough, Precise, and Fast —Carmex HBA carbide grade is available today for tomorrow’s materials10/21/2020 As more applications require the use of super-hard alloys, manufacturers are demanding tooling that can deliver precision threads and high production in less time. To meet these challenges, Carmex Precision Tools Ltd. has engineered carbide grade HBA — an extra-fine, submicron grade with high toughness for optimized performance on hardened steel Titanium and super alloys including Hastelloy, Inconel and Nickel base alloys up to 62 HRc. Available for internal and external threading in both 60° and 55° partial profile, as well as ISO metric and UN, HBA delivers high wear and heat resistance and excellent edge stability. The unique combination of carbide substrate, coating type and edge conditions provide superior performance over extended tool life. Case Study in Threading D2 at 53-56HRc In a recent test involving an external right-hand thread:

Hard machining is increasingly becoming the rule rather than the exception in complex part production. Carmex HBA was engineered to meet the challenges inherent in threading hard materials while delivering high production and longer tool life. Bring us your most challenging hard threading applications and lets try the new Carmex HBA engineered performance carbide .

0 Comments

We are very excited to announce that we are now able to offer on-site technical training to YOUR machinists at YOUR location! This is offered at no charge to customers who use any of the manufacturer's whom we represent in California and Nevada. However, just because you don't purchase things from us, don't feel left out! We also offer on-site topic specter training on any of the following topics for $150/hour. Each presentation lasts about 2 hours. The presentations last approximately 45-60 minutes with the remaining time for Q&A and discussion about unique applications in your facility.  Training Classes Available: Machining 101

Advanced Part Manufacturing:

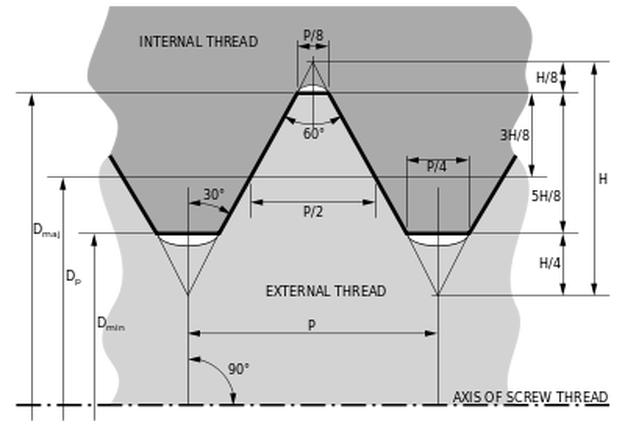

Next Generation Tooling is excited to offer some new services coming in 2015! Below is a very fast video of our new training series on Tapping which we can present to your manufacturing team at your site. It's a comprehensive overview of screw thread terminology, thread forms, fundamentals of threads, classes of fit, Tap basics, types of chamfers, the tapping process,tap types, screw thread inserts, helix angles, core diameters, re an hook angles, thread reliefs, pitch tolerances, H limits, Tap substrates, Surface treatment and coatings, tapping speeds, tap drill sizes.

This article originally appeared in decomagazine March 2013 entitled "Real Thread Whirling" Edited September 30, 2020 by Bernard Martin to add new video and additional content. “Thread Whirling” has become a popular process for Swiss machines, especially among bone screw manufacturers. Although most Swiss machine engineers agree that thread whirling delivers outstanding productivity with the highest efficiency vs conventional single point threading, not all engineers know the “Real Thread Whirling” process. NTK first released thread whirling tools with (9) inserts back in 2008. NTK engineers never perceived thread whirling as a complicated process. The complication was not with regards to machining difficulty but in producing the perfect thread form described on the print itself. The so called “Bone Screw” is a major part produced by the thread whirling process. It is quite unique, compared with the other industrial screws, since there are no female threads to mate. Bone screws are attached directly into human or animal bones for medical repair applications. The screw is not expected to be loosened at all once it is fixed in place. The characteristics of bone screws are: larger pitch size and larger screw depth and length as their key function is to be tightened into bones rigidly and as quick as possible. As a result of this uniqueness, inspection of screw forms has become extremely difficult. Due to the larger helix angle to make a high pitch thread form, you cannot visually see the cross section at all with a common optical comparator. What you can check with an optical comparator is only the peripheral or bottom diameter of the thread. The only way to measure the real thread form of a bone screw is to inspect it with a (CMM) Coordinate Measuring Machine. However, there are not many manufactures which use CMM type of measurement machine for the inspection after machining. Most of them focus on visual inspection of thread form and surface roughness and use an optical comparator for the final inspection. Another surprise for NTK engineers, is the fact that even in manufacturers that have the very latest machines, well experienced and highly educated staffs, the engineers make small adjustment on a helix angle or pitch size when they cannot get the ideal thread form. As you may understand, if you change the helix angle or pitch size, thread form itself could be totally out of print specifications. Why does this happen? One factor comes from the uniqueness of bone screw: There is no female thread. That is, if the thread form is made close enough to the print, the screw can perform its function to be tightened rigidly to a bone since there is no mating surface (female thread). The other comes from difficulty in designing thread whirling inserts due to complexity of thread form itself. Having a visual image of thread whirling process in your mind is extremely difficult. Thread whirling inserts are set on the round cutter body and the cut- ter is attached to the spindle which is tilted with a helix angle. The spindle revolves at a higher rotation (like 3000 rpm) while the bar stock revolves in the same direction but at a much slower rate like 10-30 rpm. During this rotating process, each thread whirling insert machines the bar stock while they rotate much faster than the bar stock. The spindle and the inserts tilt to make thread form and the inserts shave or cut bar stock not only at the center of the bar stock but also the upper or the lower side of the bar stock. Conventional, single point threading inserts are designed with exactly the same thread form as the thread itself because it always machines with regards to the center of the bar stock. On the other hand, thread whirling inserts cannot be designed with the same concept because the actual machining point always varies on the upper or lower side of the bar stock. However, there are some competitor’s thread whirling inserts designed with the identical methodology as single point threading. With this incorrectly designed thread whirling inserts, bone screw manufactures are frequently required to re-make the inserts, in some cases, not one time but several times. Or, they are forced to make inappropriate manual adjustment on the helix angle or pitch size to obtain the thread form which looks closer to the prints specification. NTK thread whirling does not require such guesswork process manipulation. Thanks to the design capability of our inserts we can obtain perfect threads right from the start. This process designing technology is now patented. Recently, to reduce surgery hours, bone screws with double lead threads are becoming more popular. This industry trend is creating another challenge for most bone screw manufacturers. Producing double lead bone screws require longer machining times than single lead screws. Most manufacturers machine the 1st lead within the guide bushing length and then machine the same length with the 2nd lead while the guide bushing is still holding on to the bar stock. As a result, they need multiple passes to achieve a double lead thread form bone screw. If the bone screw is very long then this process has to be repeated the full length of the bone screw which is a more time consuming process. As you can imagine, single pass machining of the double lead bone screw is the best solution to improve productivity. To enable single pass machining of double lead screw, both inserts must have a different geometry ground on 1st and 2nd threads. This is simply because thread whirling machining is calculated with regards to the upper and lower point of the screw’s centerline. This process generates the double lead bone screw in a single pass cutting both the 1st and the 2nd leads at the same time.

NTK thread whirling designing technology and highly accurate insert grinding ability can produce the per- fect thread whirling inserts the first time. This feature enables double lead bone screw manufactures to achieve single pass machining. We believe that you will appreciate NTK’s highly advanced thread whirl- ing system technology once you use NTK’s double or triple thread whirling tools. When your machine is equipped with the correct helix angle setting, correct tool setting and a NTK thread whirling system, you will experience “real Thread Whirling” which can produce perfect thread form screws. NTK is looking forward to your inquiries from those who eager to have perfect thread form from the beginnings, of course with no incorrect manual adjustment, or to improve your double, triple lead screws productivity.

The ISO metric screw threads are the world-wide most commonly used type of general-purpose screw thread. They were one of the first international standards agreed when the International Organization for Standardization was set up in 1947.

The "M" designation for metric screws indicates the nominal outer diameter of the screw, in millimeters e.g., an M12 screw has a nominal outer diameter of 12 millimeters.

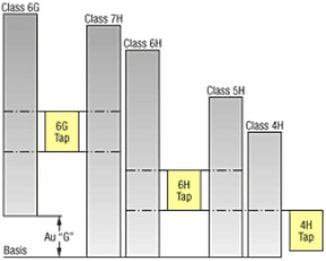

4H and 6G taps can be supplied upon request. 6G taps are Oversize. Please refer to the Au "G" values table below.

For the special tolerance "7G", an oversize of approx. 2 x Au "G" has been taken into account. Tolerance Chart - Metric Coarse / Fine

Tolerance Chart - Oversize 6G Taps Au "G" Values for Oversize Taps "6G Taps"

|

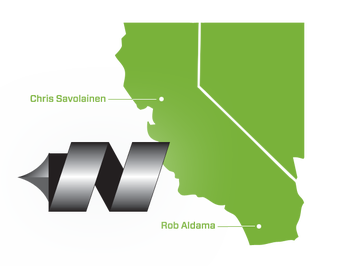

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed