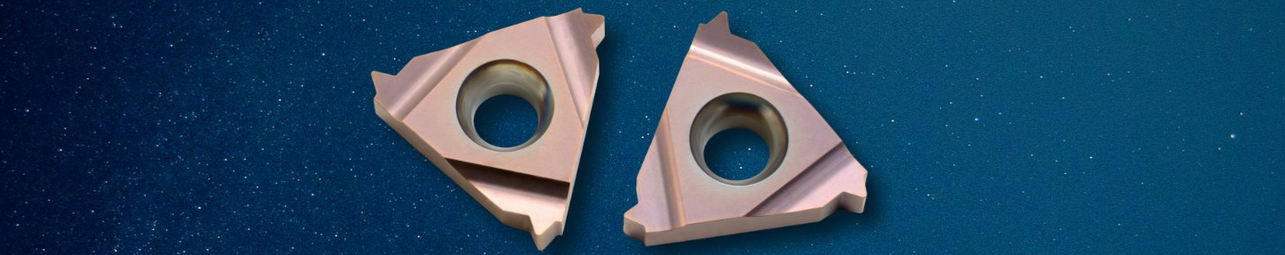

Tough, Precise, and Fast —Carmex HBA carbide grade is available today for tomorrow’s materials10/21/2020 As more applications require the use of super-hard alloys, manufacturers are demanding tooling that can deliver precision threads and high production in less time. To meet these challenges, Carmex Precision Tools Ltd. has engineered carbide grade HBA — an extra-fine, submicron grade with high toughness for optimized performance on hardened steel Titanium and super alloys including Hastelloy, Inconel and Nickel base alloys up to 62 HRc. Available for internal and external threading in both 60° and 55° partial profile, as well as ISO metric and UN, HBA delivers high wear and heat resistance and excellent edge stability. The unique combination of carbide substrate, coating type and edge conditions provide superior performance over extended tool life. Case Study in Threading D2 at 53-56HRc In a recent test involving an external right-hand thread:

Hard machining is increasingly becoming the rule rather than the exception in complex part production. Carmex HBA was engineered to meet the challenges inherent in threading hard materials while delivering high production and longer tool life. Bring us your most challenging hard threading applications and lets try the new Carmex HBA engineered performance carbide .

0 Comments

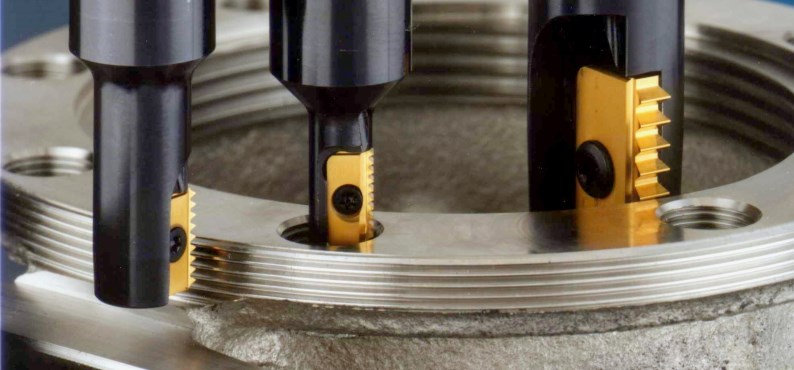

The DMT/DMTH tool family consists of high-performance tools that can be used in the production of internal threads. The circular motion performed by these tools during operation produces the thread hole, the actual thread, and an (optional) chamfer in a single work process. This eliminates the need to switch between tools, saving valuable time.

DMT - THREAD MILLS WITH INTERNAL COOLANT BORE Features:

Made from Carmex MT7 Carbide Grade:Sub-micron grade with multi-layer TiAIN coating. This is a general purpose grade, which can be used with all materials. (ISO K10-K20) TECH TIP: For left-hand jobs, use the M04 code in your G-Code programs. DMT - THREAD MILLS WITHOUT INTERNAL COOLANT BORE Features:

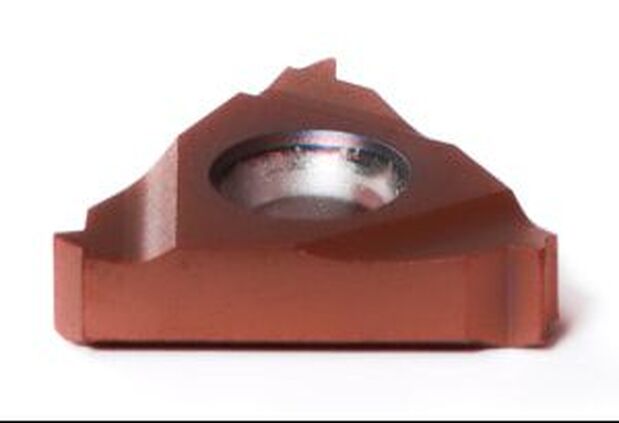

Made from Carmex MT7 Carbide Grade:Sub-micron grade with multi-layer TiAIN coating. This is a general purpose grade, which can be used with all materials. (ISO K10-K20) TECH TIP: For left-hand jobs, use the M04 code in your G-Code programs. DMTH – 3 IN 1 FOR HARD MATERIALS Features:

Made from Carmex MT11 Carbide Grade:Ultra-fine sub-micron grade with triple blue PVD coating. TECH TIP: For left-hand jobs, use the M04 code in your G-Code programs. The first step toward understanding thread milling is knowing its advantages and exploring where it could fit in your operation. Although many operators would have no trouble visualizing the use of thread milling on larger size parts, advances in the technology have made it an extremely advantageous choice for even the smallest holes. Most of our customers discovered thread milling — and Carmex — when they consulted their industrial distributors about problems they were having with taps. As parts have become more complex and materials harder to machine, the disadvantages of tapping has become more apparent. By virtue of their design, taps are prone to breakage. The extraction of a broken tap can cause real problems in high-value parts that demand precision thread finishes — not to mention the lost man-hours involved. A frequent cause of breakage involves chip overload, and chip removal has continually been a problem in tapping. For this reason, the use of taps on NC equipment has always presented challenges due to breakage and thread quality. A further disadvantage is the inability of a tap to thread to the bottom of a blind hole. This requires an extra allowance for clearance that is both undesirable and unnecessary. Shorter tool life is another problem and, in automated situations, requires redundant tooling that takes up space in the tool magazine. Thread milling, on the other hand, avoids the difficulties associated with tapping since it not only delivers better chip control but can proceed unimpeded to the bottom of the blind hole. Because of thread interpolation and the use of solid carbide and indexable tooling, breakage is eliminated, vibration is reduced, and a more precise thread and better finish are generated. This in turn translates to greater economy through longer tool life and increased dependability, especially on CNC machines or automated equipment. Versatility is likewise a consideration. Thread milling can be utilized on holes as small as 0.25″ up to the largest sizes. All standard thread profiles are available and, for specialized applications, custom-made tools can be produced, tested and delivered to match tight production schedules. Thread Mill Features

Besides the advantages inherent in thread milling, Carmex offers customers further benefits. Years ago, Carmex engineers perfected the tool design they refer to as their “Helical Advantage™.” By smoothing the engagement of the tool, their products can operate at higher speeds, ensure precision threads, and deliver better overall finish. The Helical Advantage is also a major factor in extending tool life. Before we forget, its also worth mentioning that you should also check out the Carmex Tool Wizard software to speed your start-up. Most important, our Next Gen Tooling team is thoroughly trained and ready to assist you, not only in getting started, but in selecting the right tools for your applications. Whether your operation involves large transfer type equipment, conventional CNC machines, automated lines, or high precision Swiss-style machining, we’ll be happy to work with you to develop the best solutions to your individual needs and advance your processes to the latest in thread milling technology. Over the years, many of our customers have come to us because they were regularly breaking taps.

This meant that the holes had to go from a depth of .150" to .190". The 2-56UN thread’s major diameter was .086", and the drill diameter .070".

Repeatability was nearly impossible on his CNC equipment, and he literally came in every Saturday to tap the holes by hand. When he started talking with us, he was breaking his taps after only 20 holes — an extraordinarily short tool life. By re-examining his technology, and switching to Carmex Precision thread milling, he was able to accomplish the threading of 683 holes with a single thread-mill on his CNC equipment. Despite the number of passes, the wear factor between the first and the last holes could only be measured in tenths, and the customer was able to get the thread detail back to its original .150" full thread depth. Perhaps just as important, his Saturdays are now “tap-free.” |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed