|

As the CNC manufacturing industry continues to grow we're meeting more and more new people coming into our industry. Although many experienced machinists have lots of knowledge, we're finding that the new people are asking questions about some things that may be common knowledge to the old hands. One of the questions relates to "Why the heck is the cone on the toolholder the angle that it is?" We're here to help answer that.... By now, many have undoubtedly heard that most steep taper (CAT, BT) Toolholders hold an AT3 taper tolerance or better. So what exactly is AT3? Steep Taper, Fast Tapers & Locking TapersBefore we get into the tolerance and specs it's important to understand that there are basically two classes of tapers:

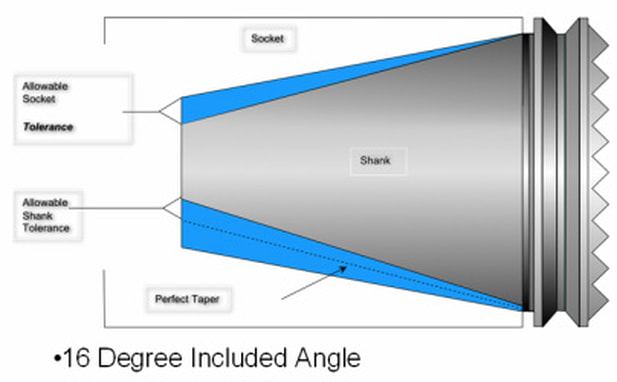

Most of the taper standards originated in the early days of the aircraft industry with rotors and propellers. There's quite a bit of thought that went into why the two types of tapers exists: It has a lot to do with "Van der Waals Forces" if you want to know about it in more detail. What's important to know is that CNC spindles are made with Steep Tapers. Why? Well, just as the two names state the first is "locking" taper and the second is "free-releasing" Since Toolholders have to be automatically changed in the CNC machine you want them to be as close to a locking taper as possible (8°/side) without, well, 'locking' in place (7°/side)! This is also the reason the ER/DR style collets also are made to an 8°/side angle as well by-the-way. What is an AT3 Taper Tolerance?That brings us to the "AT" standard for steep tapers. "AT" is an ANSI/ASME (ASME B5.50-1994) and ISO Standard (ISO 1947 ) that runs from AT1 to AT11. Since the AT tolerance is essentially logarithmic, the lower the number the tighter the tolerance (and harder it is to 'hit' in manufacturing). In other words the difference between AT 3 and AT4 is NOT the same increase in tolerance as between AT3 and AT2. AT3 is harder to attain than AT4 and AT 2 is substantially harder to reach than the jump from AT 4 to AT3. Again, the lower the number, the tighter the 'self releasing' tolerance. Most CNC Machines steep taper spindles are made to an AT2 Specification. In order to stay competitive most all toolholder manufacturers are holding an AT3 tolerance (or better). Because there are much fewer spindles made than rotary toolholders this makes manufacturing sense. The key words here to pay attention to is "or better" Just like when you make parts in your shop to a tolerance, that doesn't mean that every part is exactly the same. The parts are within a tolerance band. That's what the "AT" defines! So when a toolholder manufacturer says "AT3 or better" that can mean that some of the holders are actually holding an AT2 tolerance... and this is sometimes the cause of the tolholders 'sticking' in the spindle:Not because they are out of tolerance, but because they are actually holding a closer tolerance! (...nearer a locking taper) By-the-way, most all steep taper toolholders are made from some derivative of 8620 steel and then case hardened. Steep Taper Rotary Toolholder are Taper DrivenSo although most people think that the drive dogs on the spindle are doing the 'driving' of the rotation of the toolholder, it's actually the taper connection that is driving the rotation of the tool. If that wasn't the case, then you would see the drive dog notches in the toolholder start to show signs of wear when the spindle impacted them all the time. Afterall, the 8620 is only case hardened.

There are a couple of last things to make note of and think about:

Some further reading:

1 Comment

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed