|

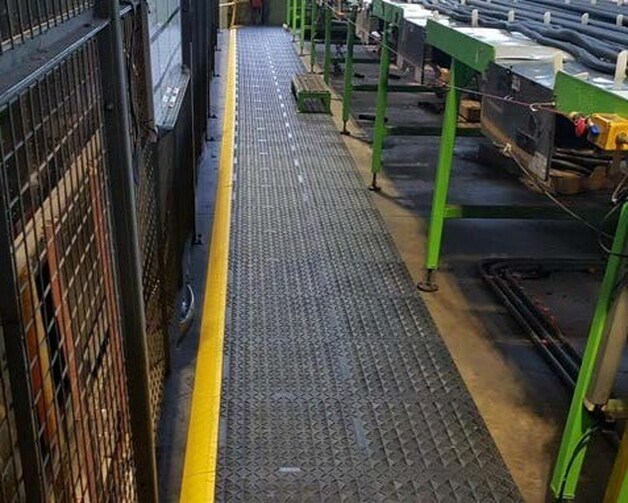

In industrial supply chain management, where the demands for efficiency and cost-effectiveness are ever-present, comes this story of innovation and strategic partnership that not only underscores the value of a keen eye for detail but also the profound impact of choosing the right solutions for seemingly mundane problems. Tasked with overseeing the supply of everything from safety gloves to industrial vacuums and grinding discs, our distribution partner Kyle's role transcends mere product delivery. His commitment to providing not just products but value led him to identify and address a costly inefficiency in the customer's use of matting—a move that would catalyze a shift towards the adoption of Safe-Flex solutions, setting a new standard in workplace efficiency and safety. Kyle has been with his employer, one of our top distribution partners, for a number of years and he's Integrated into his customer’s facility, Kyle spends the bulk of his week here, fulfilling the supply chain needs for this one customer. From gloves to industrial vacuums, grinding discs to anti-fatigue mats, this facility relies on Kyle to bring not only the best products, but the best value. Last year, Kyle realized his customer was spending a lot of money on matting, often replacing it quicker than they would drill bits. He built a case for, and strongly suggested they take a serious look at Safe-Flex. “They were replacing mats, in some stations, on a monthly basis. When you do the math, the savings in using a better product is right there.” Kyle’s customer started with our Safe-Flex Workstation Kits, the simplest way for new customers to get acquainted with Safe-Flex. Safe-Flex are pre-packaged kits, that accommodate 3’ x 3′, 3’ x 5′ and 3’ x 8′ work spaces. The packages include all safety edging and install instructions. Options include closed and open anti-fatigue mats, as well as ESD, Antimicrobial and anti-slip grit matting solutions.

Are you spending too much money on matting? Are you mats shredded and need replacing? Give us a call!

0 Comments

When it comes to broad capability, there are a few clear machine tool choices that production units and shops consider most – Five-axis, Vertical and Horizontal Machining Centers. The criterion for choosing looks different depending on what seat you sit in – from ownership to management to purchasing and finance – but from the shop floor perspective it’s all about making chips.

Getting the most out of these highly sophisticated machines involves a combination of processes, programming, tooling, workholding and human creativity. Set up between them is very different, too. Workholding on a 5-axis and Vertical Machining Centers is very straight forward – literally – since the spindle points directly to the table. Setting up a Horizontal Machining Center (HMC) requires quite a bit more thought because the spindle points to . . . well nothing, just into the open space within the machining envelope. So, what’s the call for it? Over the years, HMCs have evolved from single station to double, with the use of pallet changers, to pool pallets for multiple setups, and now to even include hydraulics within the pallet to load and clamp on the machine. And the evolution continues. Today’s HMCs have great productivity characteristics including the ability to continue machining in one location while part change can take place in another. Many feature automatic tool changers and automatic pallet changers making them well-suited for uninterrupted, unmanned and continuous machining. Configurations with multi-axis spindles also permit true five axis machining. And thanks to gravity, the chips naturally fall away from the parts. To meet this great potential, requires a review of several workholding issues at the outset. 1. Angle Plate or Tombstone First, let’s get back to the open-air orientation. All machining on an HMC starts with a workholding solution. That’s either going to be an angle plate or tombstone (column) that mounts to the HMC indexing table to provide the position and orientation of the workpiece to the spindle. The choice of this fundamental base is dependent upon the answers to remaining things to consider. 2. The Four Basics As with all machining, all fundamental requirements must be met. Workpieces must be held securely. They must be positioned to allow access to machine all sides (ideally without having to change). Operations have to be repeatable (within tolerance). And the setup has to be designed to be easy for the operator. That includes the ability to clear chips, load, move and other ergonomic factors with the safety of that individual always being priority one. 3. What is your current need? If you’re gearing up for the next run of parts, it’s best to begin with an SOW (Scope Of Work) including everything from what you’re looking to accomplish now, to opportunities for greater productivity, and how to best support operator skill level. 4. What is down the road? On the heels of that, savvy engineers are mindful of future needs. Plan for it now and be ready when the demand arises. This past-the-horizon approach saves time for further utilizing technology such as incorporating robotics and other automation. 5. Opportunities for increased productivity There are two additional productivity boosters available depending on the application. The first is the move from an angle plate to a tooling column for the ability to load a greater number of workpieces for any given setup. This is just a matter of math – a two-sided column essentially doubles that number, three-sided triples, and four-sided quadruples. For every incremental increase, there is a corresponding decrease in overall setup time (or downtime), and conversely an increase in productivity (or uptime). Connections are standard T-slots or grid patterns. The second opportunity is the addition of a quick-change system that allows the entire column to be removed, changed and the next one connected, fully loaded and all in a matter of minutes or even seconds. This quick on and off works when repeatability is high and avoids having to again find zero for every changeover. Finding the sweet spot for your shop’s productivity is very much a human effort, and a matter of choosing the best combination of man and machine. In the case of high producers like HMCs, the goal continues to be loading and changing parts faster than the machine can make them. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed