|

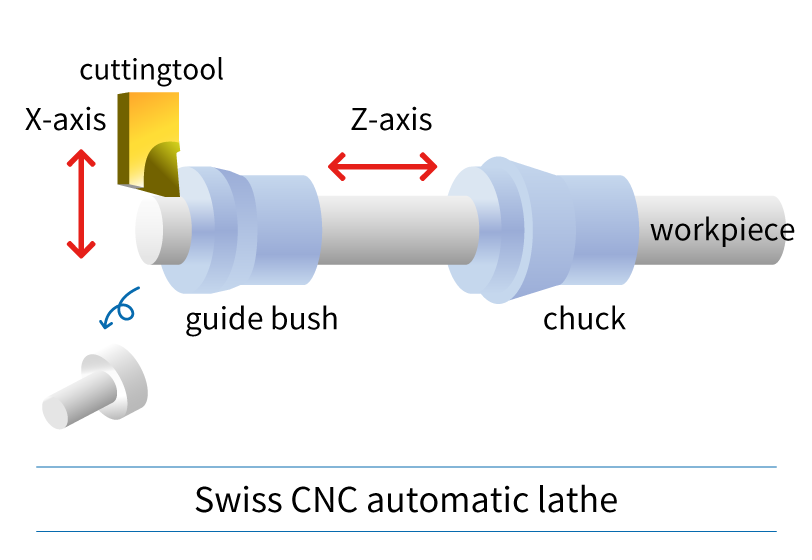

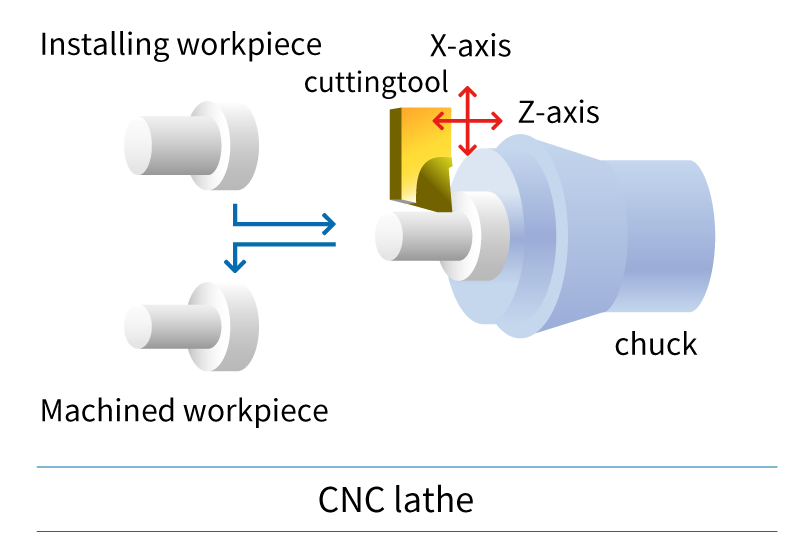

A Swiss type CNC automatic lathe and a CNC lathe, they are similar lathe machines, but did you know they are completely different? In this article, the kind folks at NTK Cutting Tools will introduce the 4 differences between the cutting tools used based on the mechanical structure of Swiss CNC automatic lathes and CNC lathes. What is the difference between a “Swiss CNC Automatic Lathe” and a “CNC lathe”?

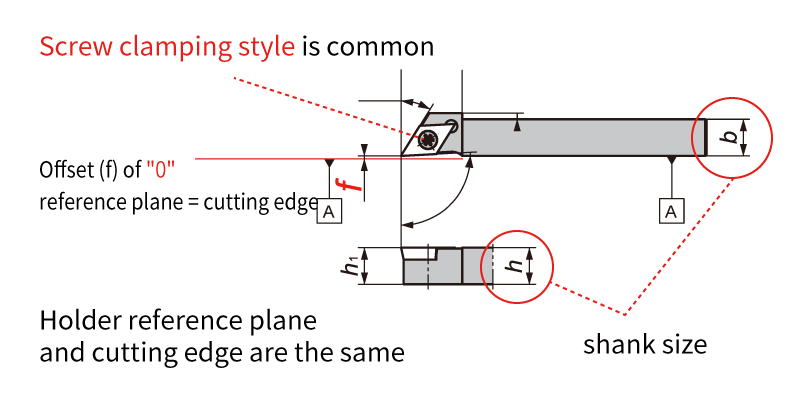

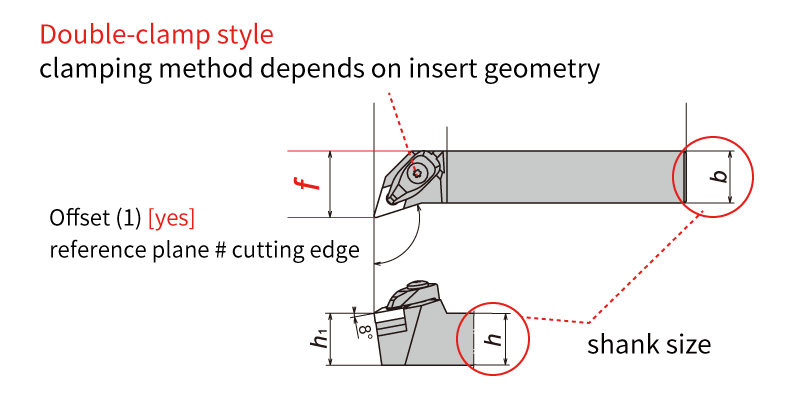

Swiss CNC automatic lathe & CNC lathe: Since the machine structure, workpiece, and size are different, it is important to select the cutting tool accordingly. Now let's take a look at the features of cutting tools used in CNC automatic lathes. Difference 1. HolderThe holder is an important component for achieving chip performance. I will explain the difference between the holder used on a Swiss type CNC automatic lathe and a CNC lathe. Holders for Swiss CNC Automatic Lathe

CNC Lathe Holders

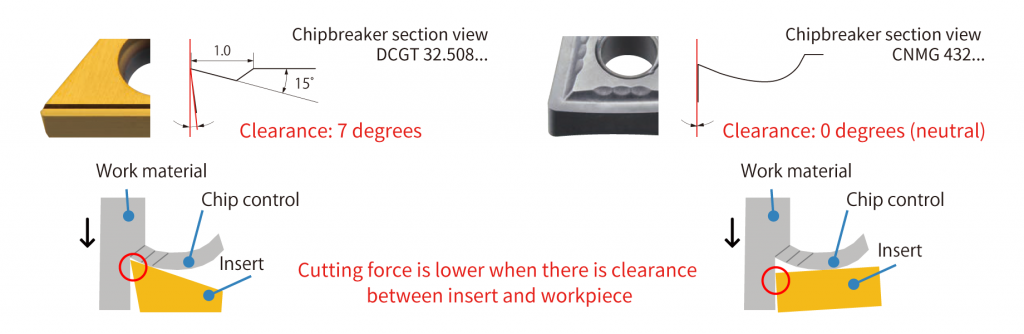

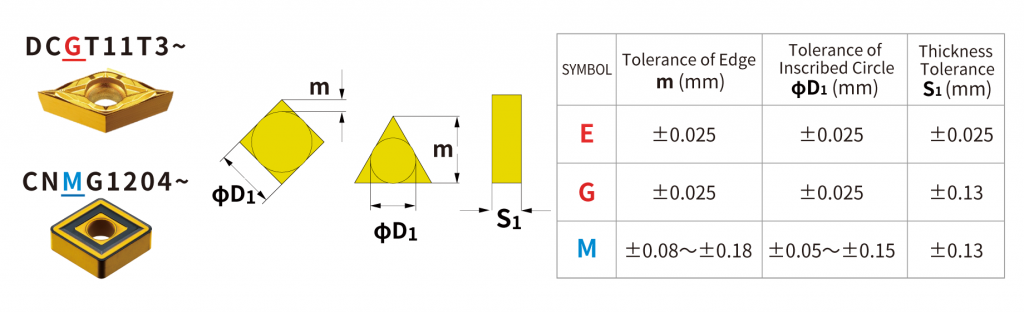

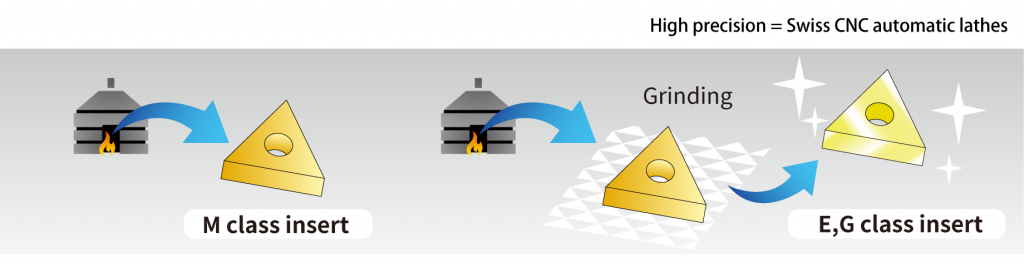

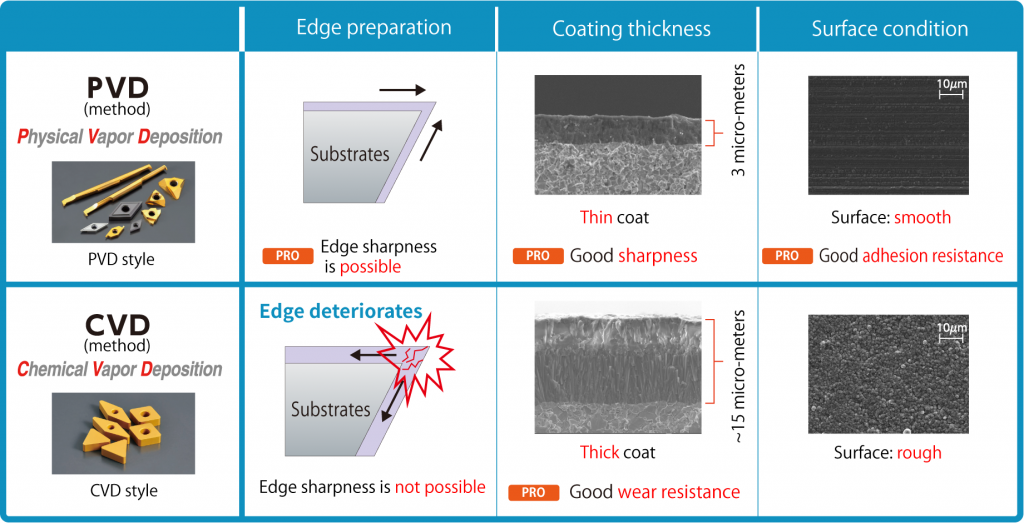

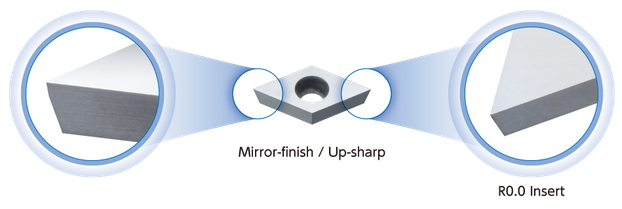

Difference 2. Insert geometry: Positive inserts and Negative insertsCNMG... DNMG...: If you are familiar with machining on CNC lathes, you likely know about insert geometries. The Swiss type CNC automatic lathe is the same type of lathe, but if you are thinking of machining with the same insert, be careful! Inserts such as "CNMG /CNGA..." and "DNMG/DNGA ..." used on CNC lathes have many corners, and the cutting edge is honed or chamfered (edge preparation) and have excellent cutting edge strength. These inserts are ideal for shearing the workpiece material. On the other hand, when a negative insert such as "CNMG/CNGA..." is used on a Swiss type CNC automatic lathe, cutting resistance tends to be high and "chatter" and "work deflection" occur. We recommend using a "positive style" for Swiss CNC automatic lathes. Swiss-type CNC automatic lathes machine workpieces that are smaller in diameter and require higher precision than machining on a CNC lathes. High cutting resistance causes “vibration” and “dimensional defects”, so using a “positive insert” with a relief angle to reduce cutting resistance and achieve stable machining. b Difference 3. Insert tolerance: G-class and M-classThe table above compares the “M” class commonly used on CNC lathes with the “G” class and “E” class commonly used on Swiss SNS automatic lathes. The 3rd letter in the insert part description identifies the tolerance class. Insert such as CNMG… and DNMG… have an M class tolerance. On the other hand, inserts such as DCGT… and CCGT… have a G-class tolerance. As shown in the table, the insert tolerance is very different between the “G” and “M” class. Corner length (m) and insert IC (dia. D1) tolerance affect the accuracy of the cutting edge position, or workpiece dimensions. Thickness tolerance (S1) affects the height of the cutting edge. Swiss-type CNC automatic lathes require high precision machining of small diameter workpieces, so “G-class” or “E-class” with higher tolerance than M-class are used. Also, the upper and lower insert surfaces of G-class and E-class inserts are polished and the outer edges are ground with high accuracy which achieves excellent sharpness. For Swiss CNC automatic lathes, it is strongly recommended to use inserts with “G-grade” and “E-class” tolerances. Difference 4. Coatings types: PVD vs. CVDCoating is an important factor in determining the performance of tools and the quality of workpieces. There are two main types of coatings - CVD and PVD. Which coating is suitable for Swiss CNC automatic lathes? Inserts like “CNMG” and “DNMG” used on CNC lathes are generally CVD coated. CVD coatings can be thick films compared to PVD coatings and have excellent abrasion resistance. But, because it is a thick film coating, it is easy to cause deterioration and there is a disadvantage of a rough coating surface. Swiss-type CNC automatic lathe machining requires high precision, sharpness is important, so PVD coatings are more suitable due to thin film coatings achieving sharp edges. As shown in the figure above, PVD coatings have excellent sharpness, dimensional stability, and welding resistance making it the ideal coating style for Siwss-type CNC automatic lathes. Do you still have questions about the difference between tooling used for a Swiss type CNC lathe and traditional CNC lathe?

NTK offers a large lineup of tools specialized for CNC automatic lathes. If you are having issues machining, please consider contacting us for technical advise.

4 Comments

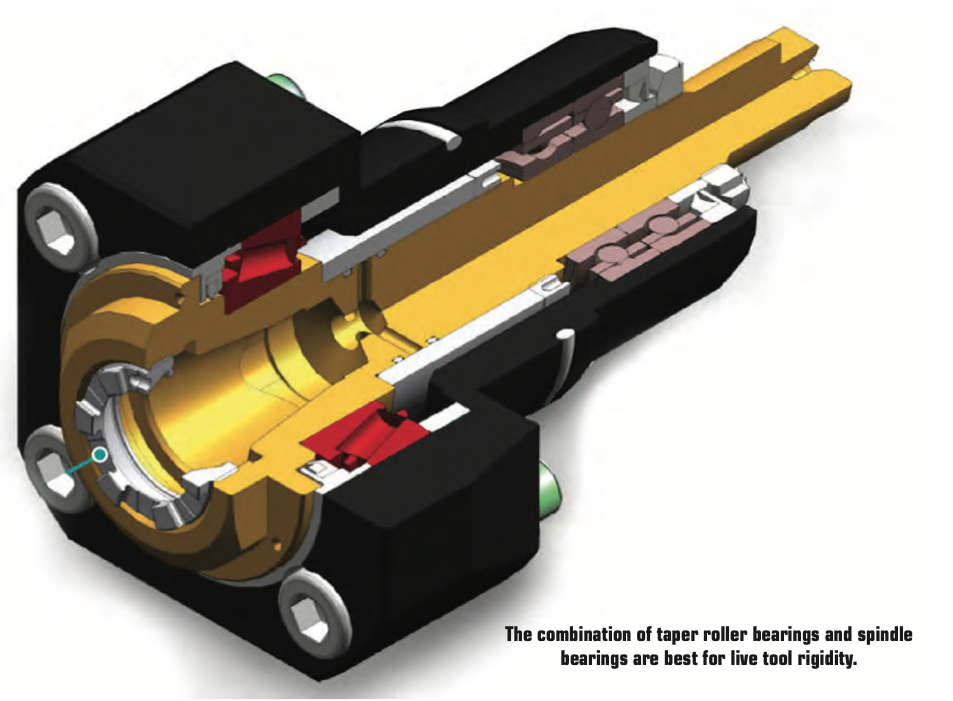

A REVIEW OF THIS MACHINING METHOD, THE BASIC CONCEPTS AND SOME EXCITING DEVELOPMENTS IN THE TECHNOLOGY by Preben Hansen, President, Platinum Tooling Technologies Inc. Live tooling, as a component on a lathe, is specifically manipulated by the CNC to perform various milling, drilling and other operations while the workpiece is being held in position by the main or sub spindle. These components, whether BMT or VDI, are also called driven tools, as opposed to static tools, that are used during turning operations. All live and static tools are built per the machine tool builder’s specification for each of the various models they produce. A key to running a successful job shop or production department is to partner with a supplier who can meet the tooling needs for all or most of the machines on your floor. Most often, live tooling is offered in standard straight and 90º angle head configurations with a wide range of tool output clamping systems, including ER collet chuck, arbor, Weldon, Capto, whistle notch, hydraulic, HSK, CAT, ABS and a variety of custom or proprietary systems developed by the many suppliers to the industry. When the need arises for a new machine tool, careful consideration should be made to determine which live tools are appropriate for your application. While a standard machine tool package will help you get started, it is important to anticipate job and volume changes, as well any unforeseen machining challenges from the beginning, in order to avoid machine downtime. This short article is meant to give you a set of parameters to consider when evaluating the live and static tooling to use in your shop or production department. Simply stated, you need to do as much evaluation of your process, when determining the proper tooling to be used, as you did when you evaluated the various machines available for purchase. This fact is often overlooked and that can be a critical error, in the long run. Your examination can range from the simple (external vs. internal coolant, for example) to the sublime (adjustable or multi-spindle configurations) to the custom tool, that may be required and built to suit your special application. Finding a supplier who has an in-house machine shop for the preparation of special tools is a great value-add. Tool life is the product of cutting intensity, materials processed, machine stability and, of course, piece parts produced. Two seemingly identical job shops can have vastly different tooling needs because one is automotive and one is medical, or one specializes in the one-off and low-volume work, while the other has a greater occurrence of longer running jobs. The totality of your operation determines the best tooling for the machines being purchased. Bearing construction and the resulting spindle concentricity drive the life of any tool. You might find that just a 10-15% greater investment in a better design can yield both longer lasting cutters and consistently superior finish on your products. Of course, the stability and rigidity of the machine tool are always critical factors. Bevel and spur gears that are hardened, ground and lapped in sets are best for smooth transition and maximum torque output. Taper roller bearings are consistently superior to spindle bearings in live tool milling applications, so look for a combination system to get the highest rigidity possible. Also, look for an internal vs. external collet nut, so the cutting tool seats more deeply in the tool, as superior performance will result. Likewise, high pressure internal coolant might be desirable. Look for 2000 psi capabilities in 90º tools and 1000 psi in straight tools.You need to ask another question, namely, is the turret RPM sufficient to handle the work to be done? It’s possible that a live tool with a built-in speed increaser, often called a speed multiplier, would be helpful. Would it be beneficial to move secondary operations to your lathe? Gear hobbing can be accomplished in this manner, as can producing squares or flats, through the use of polygon machining. Standard live tooling most often is best suited to production work, where the finish, tolerances and cutter life are critical, while quick-change systems may be better suited to the shop producing families of products and other applications where the tool presetting offline is a key factor in keeping the shop at maximum productivity. It’s a given in our industry that when the machine isn’t running, the money isn’t coming.

Dedicated tools for large families of products may often be desirable for some applications, but do consider whether a flexible changing system would be more appropriate. Talk to your tooling supplier for the various options, before making that determination. If standard ER tooling is suitable for the work, there are many good suppliers. It is important though, to pay close attention to the construction aspects noted above. For a quick-change or changeable adapter system, there are fewer suppliers in the market, so seek them out and be sure they can supply the product styles you need for all your lathe brands. Now, an application example showing clear evidence of the value of testing live tool performance... One company was performing a cross-milling application using an ER 32 output tool on a Eurotech lathe, running 10 ipm at 4000 rpm. They were making three passes with a cycle time of 262 seconds and were having difficulties with chatter on the finish, while producing 20,000 pieces per year. The annual cost of the machining was over $130,000. By using an alternative live tool with an ER 32AX output, internal collet nut design, with the same parameters, they were able to produce the part in a single pass with a smooth finish and cycle time of just 172 seconds. Over the course of the year, this yielded a cost savings of $45,000, approximately 20x the cost of the tool. The bottom line is the bottom line, as the accountants tell us. In the end, you may not need a universal adjustable tool or a multi-spindle live holder or even a quick-change adapter system but do consider all these options. Talk to your machine builder and several tool suppliers, plus the most important people in this equation, your shop personnel, as their input is invaluable to keeping you up and running in a profitable, customer-satisfying scenario. The author welcomes questions, comments and additional input from readers. Please contact Preben Hansen at 847-749-0633 or phansen@platinumtooling.com. Mr. Hansen has over 30 years in tooling and is considered a leading authority on the topic in the North American machine tool market.

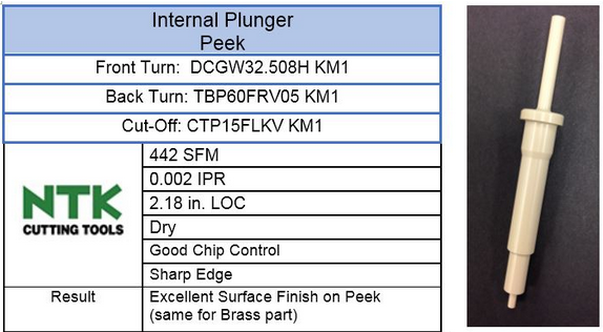

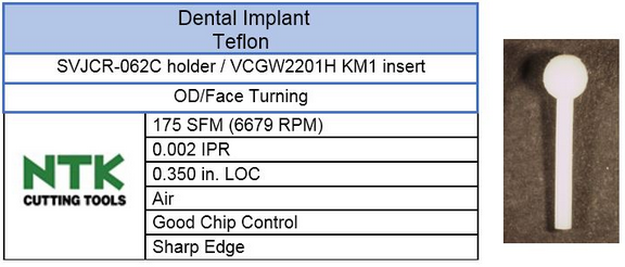

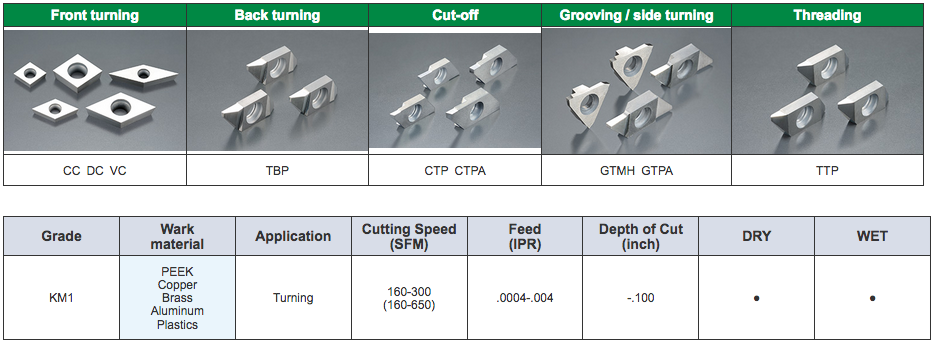

A trend that we are seeing develop in many industries, especially in the medical implant device manufacturing sector, is a rise in the number of parts being manufactured from plastics such as Peek. Polyether ether ketone (PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family. It was originally introduced by Victrex PLC, then Imperial Chemical Industries in the early 1980s. Its important to note that PEEK is a thermoplastic. This polymer is capable of being repeatedly softened by an increase in temperature. Increasing the temperature leads to a physical change. That's why cutting tool pressure and heat will impact surface finish and tool life. The medical industry has found medical-grade PEEK offers excellent strength, wear resistance and biocompatibility for components such as the dental healing caps, spiked washers and spinal implants. PEEK polymer is available in two basic grades: industrial and medical: "Industrial-grade PEEK is a strong thermoplastic that retains its mechanical properties even at elevated temperatures. The flame-retardant material is abrasion resistant, has high impact strength and a low coefficient of friction. Industrial-grade PEEK components are used in the aerospace, automotive, chemical, electronics, petroleum, and food and beverage industries. Medical-grade PEEK possesses those same physical properties in addition to biocompatibility, high chemical resistance and compatibility with several different sterilization methods. It is also naturally radiotranslucent when viewed using X-ray, MRI or computer tomography (CT). Medical-grade PEEK provides doctors with an unobstructed view of tissue and bone growth around the PEEK implant during the healing process. Some implantable-grade PEEK polymers have a bone-like stiffness and can remain in contact with blood or tissue indefinitely." There is also a glass and carbon-fiber-reinforced PEEK, which offer high wear resistance for components such as articulating joints and tends to wear out inserts rather quickly. Peek parts are generally very small, ranging from 0.039" to 0.250" in diameter, which adds to the complexity of machining the non-ferrous materials. Because of the thermoplastic properties, too much heat at the cutting edge results in Built Up Edge (BUE) and tool pressure affects part tolerance. That where NTK's KM1 grade insert work great. The inserts are extremely up-sharp edge and the mirror insert surface creates excellent surface finishes.

Things to Remember when Cutting Peek

Keys to Succesfull Machining of Peek1. Limiting Heat Build-up – The softening or melting temperatures of engineering plastics are roughly 1/10th those of metals. 2. Melting or Scorching– The thermal conductivity of plastics is low relative to metals. Most of the heat generated by machining will stay at the surface. Temperatures at the surface can rinse unexpectedly high. 3. Loss of Tolerance – If the overall temperature of the stock changes during or after machining, expansion or contraction can cause the part to fall out of tolerance. Softening of the stock can allow it to deflect at the surface under the pressure of the cutting tool. When the pressure is removed, the stock will recover and fall out of tolerance. This can frequently be managed by using lubricants and changing tooling or speed. 4. Controlling Deflection – Plastics inherently vary in their stiffness (modulus) and are more elastic at higher temperatures. The entire stock can deflect under the pressure of cutting. Proper tooling and support remains important and particular attention should be given to adequately supporting the work. Additional Resources:

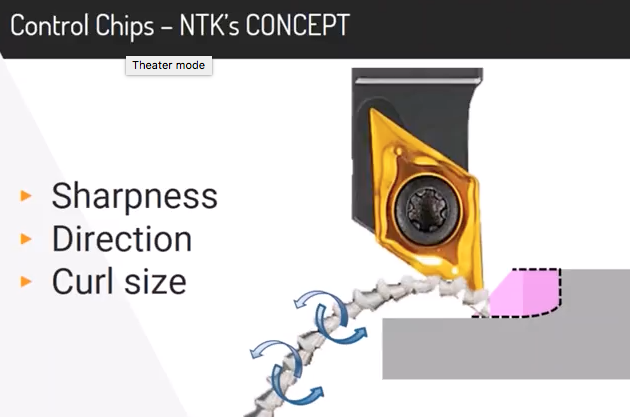

NTK Cutting Tools USA launched its first Webinar on 30th January, 2018. The featured presenter is Steve Easterday, NTK's Swiss Product Manager. The topic focuses on chips created during Swiss machining operations and the mainstream concept which is that breaking the chip is important. But is this accurate? NTK has a different concept of Chip Control. The topics covered in the video below include:

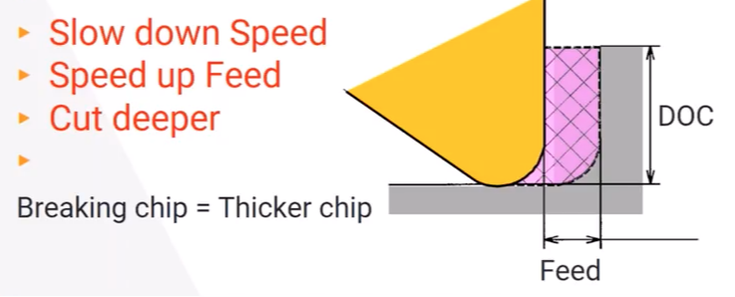

How do you break a chip?There are a few different ways to break a chip. Many people tend to think that the best methods of breaking chips in swiss machines are through the use of chip breakers on the inserts, slowing down the speed, increasing the feed, taking a bigger depth of cut and through the use of high pressure coolant. Each one of these, or some combination of them is certainly what is commonly used to gain chip control. Typically the solution is to reduce the SFM, increase the Feed Rate and increase the Depth of Cut.... but that can lead to workpiece deflection and lower production rates. NTK believes that CONTROLLING the Chips is more important than BREAKING the chips. NTK does this by doing two things:

NTK creates a "softer" chip because there is much less heat transferred to the workpiece AND the chips. The translates into better part quality, longer tool life and much more stable machining. Check out the video below for all the details on chip breakers and their toolholder solutions. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed