Jergens, Inc.

We began representation of this iconic workholding brand in our California and Nevada territories in November of 2020. Since 1942, Jergens has been a leader in new products and innovation. We represent the Workholding Solutions Group of the Tooling Component Division (TCD) which includes Ball Lock®, Bock Workholding CNC Machine Production Vises, Zero Point Mounting System, 5-Axis Drop&Lock™ Pallet Changers & Pull Studs, Fixture-Pro® Line and Quick-Loc product lines. Jergens also makes a complete line hydraulic power clamping which included Breadbox air powered hydraulic pumps.

In 1942, Jack Schron, Sr. founded Glenn Tool and Manufacturing, with his father Christy. In response to the needs of wartime production, they began to manufacture standard components in the building next door, with the goal of helping American Manufacturers operate quickly and more efficiently. “The Standard Components with the Highest Standards” became this new company’s founding philosophy, and it put Jergens, Inc. on the forefront of the “lean manufacturing” movement before anyone even thought to put those two words together.

5-Axis Workholding Fixture-Pro® Line

|

|

The first completely modular workholding system from subplates to top tooling clamping, Jergens Workholding Solutions allows you to maximize 5-Axis Machining.

The Kwik-Lok pallet changer with one screw actuation and tight tolerances that is similar to its predecessor the Drop&Lock pallet changer and pull studs |

Jergens Inc. Fixture Pro Self Centering system offers a range of vises for multiple-axis machining productivity. Available in 75mm and 130mm with a number of mounting options, the self-centering vises feature a low-profile design to allow for a greater part (machining) access

|

Part of the Fixture Pro line of modular 5-Axis workholding, the vises feature a pull-down jaw design to actively reduce jaw lift caused by flex and raising up during the clamping process. These vises have an easy centering/recentering adjustment and quick-change jaws that require no tools.

Jaws are reversible and available in step jaws with serrated inserts, aluminum soft jaws, steel soft jaws and hardened step jaws. |

Versatile mounting options are compatible with several Jergens platforms including Fixture Pro, Drop & Lock, Quick-Loc and competitive products from Lang's Quick Point, to 5th Axis' RockLock. Maximum clamping force is 3,600 lbs. at 50 ft-lbs. In combination with the full-line of Quick Loc pallet systems, the new vise offers versatility and quick-change on vertical, horizontal and multiple-axis machining centers.

Ball Lock® Workholding

|

|

Ball Lock® is the original and most widely used quick change fixture system available. Ball Lock® can be your competitive edge…just like thousands of other shops across the country.

|

|

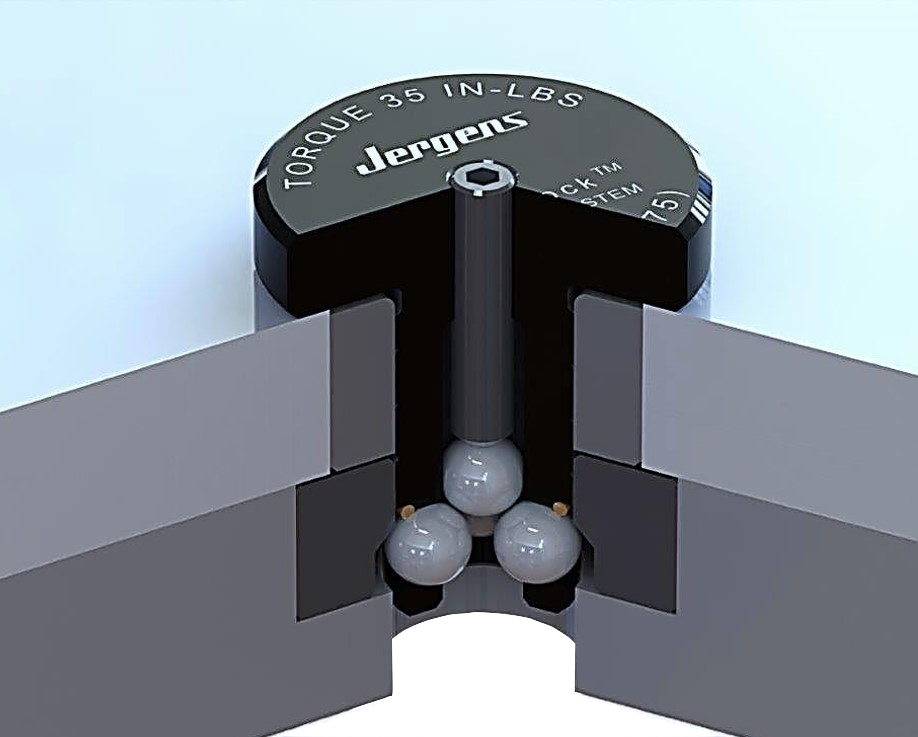

Inside the Ball Lock shank are 3 balls that expand into a tapered groove in the receiver bushing.

This action draws the plates together. The locking balls are activated by turning a setscrew in the head of the shank, which pushes a 4th ball to evenly distribute the clamping forces between the 3 locking balls. No more dowel pins or cap screws, and no need to search around for a hex wrench to remove Ball Lock® shanks. |

ZPS - Zero Point Mounting System

|

|

Jergens’ modular ZPS zero point mounting system consists of a module and a stud with a pin that allows it to be used at the bottom of a vise, bottom of the part or the bottom or back of a fixture plate. The ZPS system cuts setup time up to 90% by combining fixuring, positioning and clamping in a single operation. Available with either pneumatic or hydraulic release, the positive locking modules allow operators to quickly change out large and small machine fixtures with accuracy and minimal effort.

|

With the ZPS system, the operator can easily change out the part or the workholding and also take it right to the CMM and check for first article inspection without unclamping. Another advantage is the ability to do lights out automation with multi-pallet stations.

Bock CNC Machine Production Vise

|

|

The vises are available in 4-in. and 6-in. sizes, and produce a clamping pressure of 4,000 lb. Each vise can hold two parts, and the jaws have a total clamping travel of 0.25 in. to 0.125 in. per clamping station. Twin Vises are available individually or in turnkey automated systems with several vises mounted on Bock locator plates with all tubing and valving installed

|

Bock Workholding's Twin Vise Systems offer the fastest quick change jaw system available

Bock Workholding's Twin Vise Systems offer the fastest quick change jaw system available. The Twin Vise is uniquely designed to provide fast vise mounting on your locator plate, accurate and repeatable positioning, and fully machinable soft jaws. All Bock Twin Vise Systems offer:

Bock Workholding's Twin Vise Systems offer the fastest quick change jaw system available. The Twin Vise is uniquely designed to provide fast vise mounting on your locator plate, accurate and repeatable positioning, and fully machinable soft jaws. All Bock Twin Vise Systems offer:

|

Bock Twin Vise Systems include:

|

Tech Tip: Tooling AND Workholding: Remember that It's a system!

Remember, When you create a tooling strategy for 5-axis and 5-sided machining, you need to consider three things: clearance, reach, rigidity. But that's not all! Remember that repeatability and balance of the cutting tool and toolholder also must be maintained to achieve surface finish requirements

last edit: 11 Jan 2024

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|