Jergen's 5-Axis ER Collet Fixtures Provide Simple Clamping of Cylindrical Parts in a CNC MIll4/12/2022 Looking for a simple and low profile solution for clamping cylindrical workpieces and round bars? Do you ever need to hold a round shank workpiece and machine it in a CNC Mill?

The ER Collet Fixtures provide a simple and low profile solution for clamping cylindrical workpieces using the same technology you are already familiar with in your rotary toolholders.

0 Comments

We are very excited to announce that we are now able to offer on-site technical training to YOUR machinists at YOUR location! This is offered at no charge to customers who use any of the manufacturer's whom we represent in California and Nevada. However, just because you don't purchase things from us, don't feel left out! We also offer on-site topic specter training on any of the following topics for $150/hour. Each presentation lasts about 2 hours. The presentations last approximately 45-60 minutes with the remaining time for Q&A and discussion about unique applications in your facility.  Training Classes Available: Machining 101

Advanced Part Manufacturing:

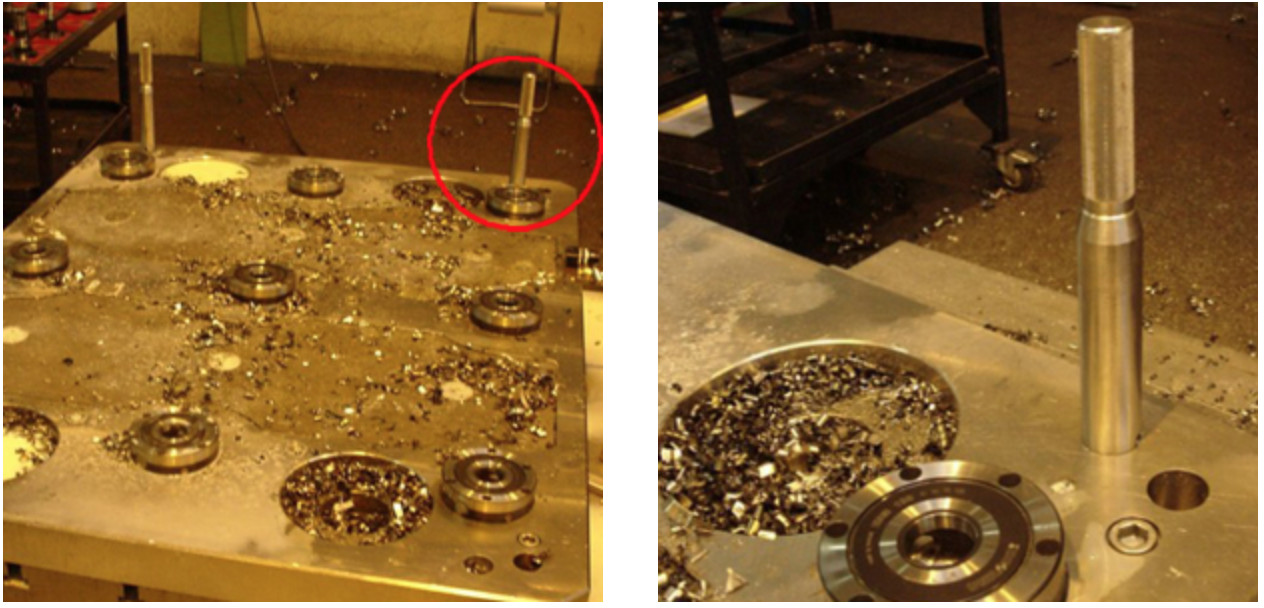

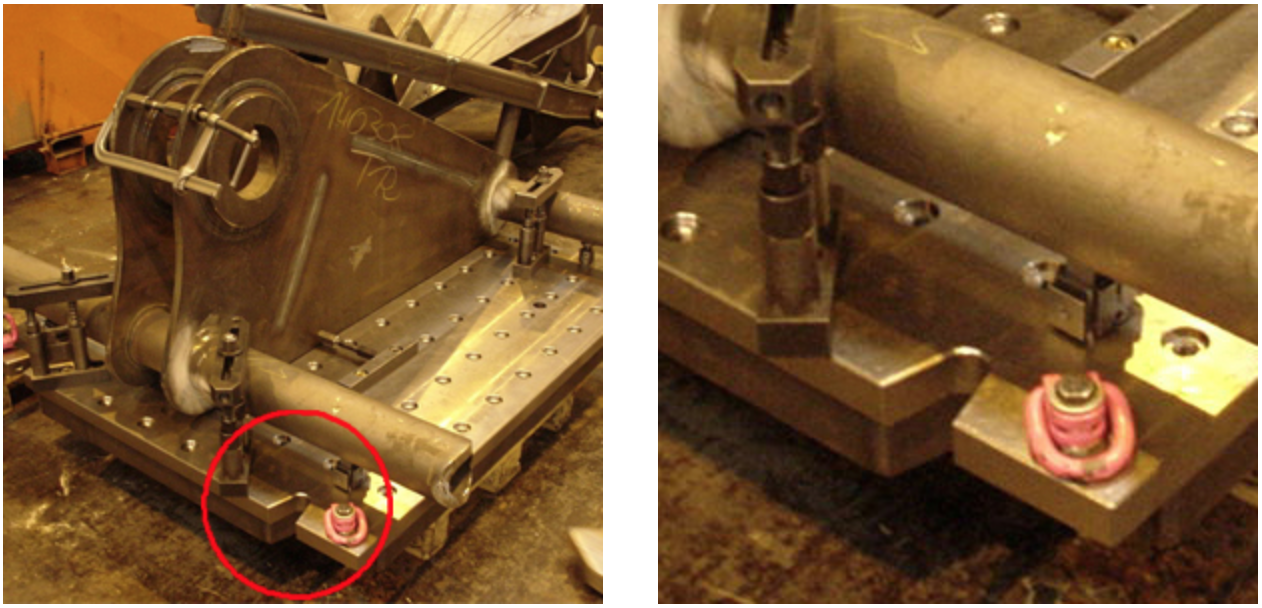

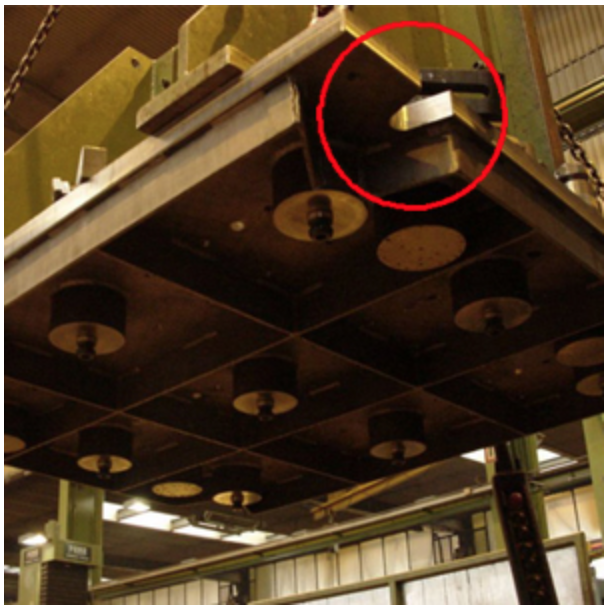

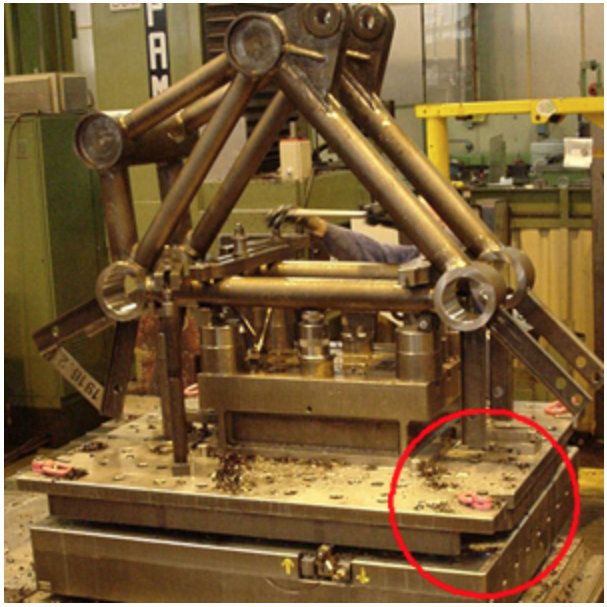

The concept of using guide pins to load large fixtures has been around for a long time, and it even applies when incorporating Unilock zero-point clamping systems in your fixturing. The main Unilock clamping knob is very robust, i.e.: very hard, and as such it can cause damage to a Unilock chuck if a fixture is very heavy or large. Guide pins are set up on the base, and their corresponding holes or notches located on the edge of the fixture pre-position the fixture so, that as it is being lowered, the knobs do not impact the critical location faces of the clamping chuck. This also has the added benefit of keeping operators in a safe location not having to use their hands & fingers to fine-adjust a slightly out-of-place fixture being lowered.

In case you missed the episode of 5th Axis vises on How Its Made, you can re-watch it right here.

This may be useful in explaining what you do in your job.... even though there's a lot of talk about "carving", "shaping" and "Sculpting" Howitsmade16 from Mathew Richard on Vimeo. Types of Workholding There are many ways to skin a cat. Dedicated fixtures have more or less fallen by the wayside just like dedicated transfer lines. This trend will probably continue for two primary reasons:

Modular fixturing is the buzzword. “Modular” takes on numerous forms from a variety of manufacturers. It can be as simple as components and clamps that are assembled into a “dedicated” fixture for a job but then can be disassembled and the components used for another job. The key to modular tooling is that you start with a good “foundation”. The foundation for most modular systems is a tombstone or subplate. Modular fixturing allow you to make “dedicated” fixtures that can be disassembled and reused for other “dedicated” fixtures. Modular fixturing is a very good solution for longer part runs or fixturing very hard to hold part shapes. SPEED is the KEY! Modular fixturing is a great idea, but as your customers begin to demand faster turnaround and smaller lot sizes just the fact that you can re-use your tooling components doesn’t always help. What matters, remember, is spindle up-time. Taking apart your components and setting up others takes TIME. So there has been a demand for new innovations from Workholding manufacturers in both modular AND Quick Change fixturing. Have you ever found yourself thinking: “I need fast set-ups, good repeatability, and quick changeover… and I want the tooling to be modular to a point where I don’t have to completely disassemble everything.” Foundation systems.Reducing set up times in workholding start with the foundation. You want to have the ability to move your fixturing from Vertical to Horizontal CNC's as lot sizes of parts increase or back to the Vertical CNC as lots sizes reduce. Foundation level systems are systems that you can build dedicated or modular fixtures on and quickly remove them for another set-up. They will also allow you to set up you fixtures off-line. That is, they will allow you to set the fixtures up OUT of the machining center. They key benefit to this is that you can still continue to make chips on one job while setting up another outside of the machine Another major benefit to these types of systems is that they will enable you to make quick changeovers. If your total “in-the-cut” machining time is 5 minutes but it takes you 10 minutes to change out the new parts and put in more raw material these system can save you a great deal of time.

There are two issues to look at when considering a certain type of fixture:

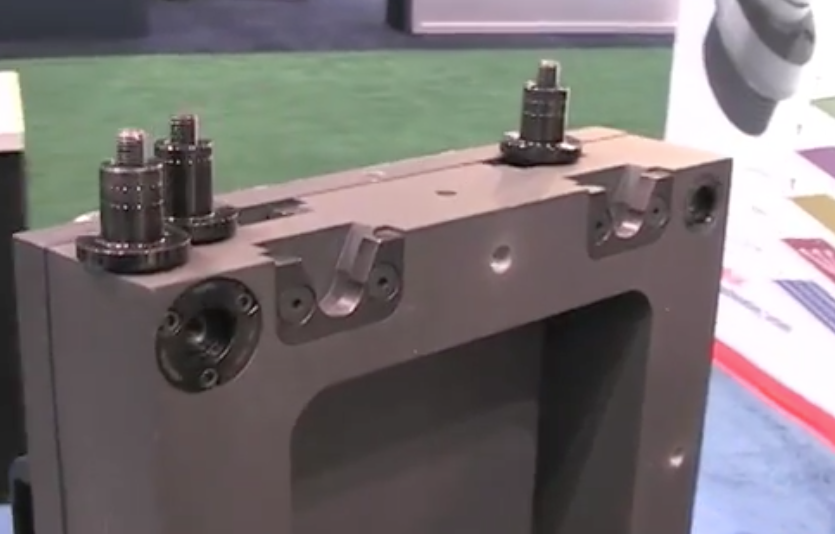

The mPower SpeedLock and ModLoc fixturing system show in the video above is one of the foundation systems that you may want to consider as part of a shop wide set up and changeover reduction process. Consider all of the types and sizes of the parts in your shop and then determine which baseplate size to start with that can provide you with the most versatility. The process of standardizing your workholding will take some time, but once complete you can move jobs around with the same simplicity as when your kids are playing with their lego's. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed