OSG Tool

Since 2004 we've represented OSG in California and Northern Nevada. They are a leading manufacturer of Taps, Dies, Drills and End Mills headquartered in Irving, TX

OSG Tool's advancements in cutting tool design and production have produced very high quality tools that are setting new standards for productivity and performance in the cutting of alloys, stainless steels, and exotic space-age materials.

OSG Tool's advancements in cutting tool design and production have produced very high quality tools that are setting new standards for productivity and performance in the cutting of alloys, stainless steels, and exotic space-age materials.

OSG Tool

1945 West Walnut Hill Lane

Irving, TX 75038 Toll Free: 800.837.2223 As part of their commitment to quality, OSG machines over three miles of material and removes over two tons of material per month in the testing of end mills alone. The commitment to quality includes a bank of CNC machining centers maintained for the single purpose of testing end mills. Through these facilities and their corporate commitment to excellence, they are able to continuously refine their cutting tool technology, improve product quality, and reduce cost to our customers, while at the same time preserving the environment. |

|

OSG Product Listing

|

ADF Carbide Flat Drill

|

|

The ADF series is not only ideal for flat-bottom hole applications, it is also compatible with a wide range of hole shapes such as inclined surfaces, curved surfaces, counterboring, half-holes, thin plates, and more.

|

Phoenix Drill

|

|

An Indexable drill series for efficient, stable hole processing.

PHOENIX® PD is an indexable drill series designed for efficient, stable holemaking up to 5XD. It is an ideal solution for a wide variety of materials such as carbon and alloy steel, stainless steel, cast iron, and non-ferrous materials. |

Taps

Spiral Flute Taps

Spiral Point Taps

Forming Taps

Straight Flute Taps

Pipe Taps

Thread Mills

|

OSG manufacturers Thread Mills for Inch (imperial), Metric, and Pipe threads. Thread mills are utilized to produce internal and external threads utilizing helical milling to produce the desired thread profile. Thread mills are typically carbide, and smaller in diameter than their corresponding tap would be, thus enabling them to fit within the ID of the pre-drilled hole. 3-axis CNC machines are required to use thread mills.

|

Check out the latest BLOGs on

OSG Tap & Die's Products!

Training Seminar: Everything your team needs to know about Tapping screw thread terminology, thread forms, fundamentals of threads, classes of fit, Tap basics, types of chamfers, the tapping process, screw thread inserts, helix angles, core diameters, re an hook angles, thread reliefs, pitch tolerances, H limits, Tap substrates, Surface treatment and coatings, tapping speeds, tap drill sizes.

Premium Tap Series for Machining Titanium Alloys

"A new series of taps is designed for machining titanium alloys. They are well suited for difficult threading applications. This new premium tap series, the EXOPRO-Ti, for putting threads in materials like titanium alloys; Commercially Pure 6Al4V & 4Al4V

"A new series of taps is designed for machining titanium alloys. They are well suited for difficult threading applications. This new premium tap series, the EXOPRO-Ti, for putting threads in materials like titanium alloys; Commercially Pure 6Al4V & 4Al4V

Variable Helix Tap Series Designed for Stainless Steel

"Constructed of vanadium high speed steel, the tap features a variable lead-flute design with chip control for stable chip evacuation. This new series provide increased consistency, improved reliability and extended tool life with water-soluble coolants. The taps are available in sizes ranging from No. 2 to 1" and M2 to M4."

"Constructed of vanadium high speed steel, the tap features a variable lead-flute design with chip control for stable chip evacuation. This new series provide increased consistency, improved reliability and extended tool life with water-soluble coolants. The taps are available in sizes ranging from No. 2 to 1" and M2 to M4."

Is there a better Shrink Fit System?

"There are a variety of Shrink Fit Toolholding Systems on the market, all of which use thermal contraction to grip cutting tools. However, while most Shrink Fit holders are one-piece type, OSG has improved upon this design with our “hybrid” Shrink Fit System.

The word “hybrid” is defined as “something of mixed origin or composition” and this is what OSG has accomplished with our shrink fit system, as our holders have the accuracy and rigidity of Shrink Fit Holders, but the versatility of Collet Chucks."

"There are a variety of Shrink Fit Toolholding Systems on the market, all of which use thermal contraction to grip cutting tools. However, while most Shrink Fit holders are one-piece type, OSG has improved upon this design with our “hybrid” Shrink Fit System.

The word “hybrid” is defined as “something of mixed origin or composition” and this is what OSG has accomplished with our shrink fit system, as our holders have the accuracy and rigidity of Shrink Fit Holders, but the versatility of Collet Chucks."

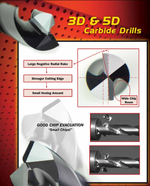

NEW! OSG HY-PRO® CARB 3D and 5D Drills! NEW!

"The new design boasts new point and flute geometry that reduce thrust forces and chip size, thereby enabling higher feeds and metal removal rates"

"The new design boasts new point and flute geometry that reduce thrust forces and chip size, thereby enabling higher feeds and metal removal rates"

Tool Geometry and the selecting the right tap for your CNC

"Understanding tool geometry and selecting the right tap for different workpiece materials can help take the anxiety out of tapping operations.Many machinists have learned to dread tapping. The story goes something like this…"

"Understanding tool geometry and selecting the right tap for different workpiece materials can help take the anxiety out of tapping operations.Many machinists have learned to dread tapping. The story goes something like this…"

Thread Milling

"Thread is processed by advancing one pitch feed per revolution in the axial direction, utilizing the planet-like rotation and revolution movements of the tool. Internal and external thread, right or left hand threads can all be produced with this one tool, simply by changing the direction of rotation and/or feed"

"Thread is processed by advancing one pitch feed per revolution in the axial direction, utilizing the planet-like rotation and revolution movements of the tool. Internal and external thread, right or left hand threads can all be produced with this one tool, simply by changing the direction of rotation and/or feed"

NEW PRODUCT!

The EXOTAP® A-Tap® is an all-purpose tap series designed to simplify tool management and to excel in a wide variety of materials and applications. The EXOTAP® A-Tap® is made from powdered metal HSS and has OSG's patented V coating to achieve excellent wear resistance.

|

The spiral flute series has adopted a variable helix flute design, which encourages stable chip evacuation and reduces cutting forces.

The spiral point series has unique geometry that enables greater chip control that can help produce tightly compacted chips for easy ejection from the hole. Features

|

advanced alloys applications chip cnc commitment cutting design die drills enabling end evacuation fit flute forming geometry hand holders hole ideal life machining manufacturer materials mills operations osg pipe point produce product provide quality reduce remove rigid series shrink spiral straight system taps technology thread titanium tool utilizing variable variety

created at TagCrowd.com

last edit 15 Jan 2024

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|