Kurt Machining Utilizes Live Tool Speed Increaser, Realizes 9x Tool Cost Savings in Less Than a Year6/12/2019 Minnesota CNC shop, and manufacturer of Kurt Vises, uses Heimatec speed increaser to up RPM and feed rate; significantly reduces cycle time on aluminum engraving application. Kurt Machining (Minneapolis, Minnesota) specializes in providing precision CNC machined parts, using state-of-the-art technologies and up to 5-axis machining. Since 1952, this 110,000 sq. ft. shop has provided its customers in a variety of high-quality demand markets with components and welded assemblies. These include aerospace, defense, semiconductor, energy, automotive and more.

Eisenshank turned to his local tooling distributor, Abrasive Specialists, Inc. (ASI) and their tooling partner, Platinum Tooling, for suggestions. Leigh Kinnan of ASI worked with the local Platinum Tooling representative, Cody Papenfus, to test run a Heimatec speed increaser, with the goal of increasing RPM on the machine and decrease part cycle time, with a documentation of the potential savings. After performing the calculations in consultation with Preben Hansen, president of Platinum Tooling and exclusive importer for Heimatec products in North America, it was determined a significant savings could be realized. Detailing the application, ASI demonstrated that a 1:3 speeder, increased the spindle RPM enough that when coupled with the nearly 3X increase in the feed rate on the machine, would produce a significant improvement to the current machining cycle. Calculating the reduction in machining cost per part and factoring the cost of the speed increaser, it was determined the use of the Heimatec product onboard the Hwacheon turning center would result in a 9X cost saving for the customer, in the first year’s production run on this engraved aluminum component.  As Shawn Eisenshank notes, “This is one of those classic scenarios, where the theoretical has proven out in practice, as we’ve seen exactly the results ASI and Platinum Tooling proposed in their test calculations.” Cody Papenfus of Hexis in Plymouth, Minnesota, who is the area rep for Platinum Tooling adds, “We say we put our expertise to work at the spindle of the machine and, in this case, that’s exactly what happened. The speed increaser performed as expected, the customer got the results promised and it was a win-win, for all. We serve our customers for the long haul and successes like this one are the big reason.” Kurt Machining performs both vertical and horizontal milling and turning, complex assemblies and weldments, delivering with rapid lead times. CAD compatibility is offered for web-based communications and fully interactive manufacturing engagement for its customers.

The company performs contract manufacturing in high quantity as well as prototyping for new designs. Kurt also performs impact extrusion, heat treating and cleanroom operations including ultrasonic cleaning of stainless steel and aluminum components and assemblies, with cleaning to Class 1000 with 100 protocol. The company is ISO 9001:2015 and AS9100D plus NADCAP Certified. Kurt Machining is quality certified by the U.S. Government to MIL-Q-9858 and MIL-I-45208.

0 Comments

Ohio manufacturer of oil field equipment saves 184 hours on one high-precision cutting tool head made of Nitralloy® PMC-Colinet has a long history in the pipe and tube market, having started in 1912 and introduced the world’s first carbide-tooled pipe threading machine in 1958. Today, the company is established as a primary supplier of machines to the OCTG sector. Its customers include integrated steel mills that sell finished pipe and couplings to the oil and gas industries, specifically using the company’s machines for threading products for downhole drilling applications. PMC-Colinet also supplies cutting tools, consumable tooling, aftermarket parts and field service to the industry. Recently, PMC-Colinet did an assessment on one very challenging job, namely, cutting keyways into large sections on a high-precision cutting tool head made of Nitralloy. For many years, the production had involved the use of a shaper to produce the keyway in the bore of the die head. Typically, the bore ranged from 6” to 13” in diameter and more than 12’ in length. These keyways have extremely tight tolerances, with location at +/- 0.0005”, width at +/- 0.001” and depth to +/- 0.0025”. One style of cut is a 3-step keyway that does not run all the way through the bore, stopping at a window that is milled from the outside diameter. This situation prevented the PMC machining department from using a ram EDM to produce the keyway. The only options previously used were to rough the keyway on an old shaping machine, then send it out for ram EDM. This process required 50 hours on the shaper, plus approximately a week for the ram EDM. Another option was to do the job entirely on the shaping machine. Roughing the keyway had to be much more precise and usually required about 61 hours. Plus, an additional 145 hours were required to finish the part, normally. These times included 10-12 hours for set-up. The team at PMC, led by Milling Foreman Rick Kokish, decided to explore other methods to produce this part on its Monarch 175B VMC. They conducted an exhaustive search on the Internet, turning up over 133,000 hits for 90º angle heads. After more than 30 hours of gleaning out the unsuitable products, they narrowed the search to just two vendors. Both manufacturers visited the facility and brought out their standard angle head designs. One of the companies, Heimatec, quickly realized this job would require a custom 90º head design to satisfy all the requirements. One competitor brought a standard 40 taper tool, while Heimatec presented a larger, heavier 50 taper unit. A week later, Preben Hansen, Heimatec’s president, supplied a drawing for the proposed custom product. PMC engineering reviewed both the standard and custom designs and awarded the project to Heimatec. The angle head supplied was designed to perform a wide variety of cutting tasks on the various end products produced by PMC. On the keyway in a bore 6” in diameter and 12” in length, using the Heimatec 90º head, PMC spent 6 hours in setup, 3 for roughing and 3 for finishing, plus 12 to 16 hours of actual cutting time. This represented a total savings of 184 hours on a single part. Though the head appeared too slender to remain rigid during the entire cutting cycle, according to PMC sources, the performance was deemed very successful. Heimatec’s head design for this custom radial drilling and milling head features an adjustable tool stop, 3 support pins for stabilizing the tool, CAT 50 taper style, 360º indexable pivot on the angle head and inclined tooth gear design for maximum rigidity.

During the project, Preben Hansen from Heimatecc supervised the installation. After the stop block attachment and grinding of the supports pins for the head were accomplished in just one day, the head was mounted and several experimental cuts were performed. Hansen spent time with Rick Kokish as well as CNC programmer Barry Spence at PMC, discussing various options for programming the head on the Monarch VMC. The very next morning, the setup was performed and an actual keyway was roughed. Results ongoing have continued to satisfy all requirements, according to PMC sources. by, Preben Hansen is President of Heimatec Inc. Live tooling is driven by the CNC control and the turret of various spindle and powered sub-spindle configurations on CNC lathes to perform various operations while the workpiece remains in orientation to the main spindle. These devices, whether BMT or VDI, are also called driven tools, as opposed to the static tools used during turning operations and are usually customized for the particular machine tool builder’s turret assembly. A common error is often made by accepting the standard tooling packages provided by the builder. This is not a criticism of the standard packages from builders, but this article is meant to give you a set of parameters to consider when evaluating the tooling and toolholding devices to use in your shop or production department. Do as much evaluation of your process, when determining the proper tooling to be used, as you did when you evaluated the various machines available for purchase. Identical Job, Different Tooling RequirementsTool life is the product of cutting intensity, materials processed, machine stability and, of course, piece parts produced. Two seemingly identical job shops can have vastly different tooling needs because one is automotive and one is medical, or one specializes in the one-offs and low-volume work, while the other has a greater occurrence of longer run jobs. The totality of your operation determines the best tooling for the machines being purchased. Bearings & Gears Bearing construction and the resulting spindle concentricity drive the life of any tool and you might find a 10-15 per cent greater investment in a better design can yield longer lasting cutters and consistently superior finish on your products.

Coolant, RPM & 2nd Op Considerations Also look for an internal vs. external collet nut, so the tool seats more deeply in the tool, as superior rigidity will result. Likewise, coolant high pressure might be desirable. Look for 2000 psi in 90o and 1000 psi minimum in straight tools. Standard live tooling is best suited to production work, where the finish, tolerances and cutter life are critical, while quick-change systems may be better suited to the shop producing families of products and other instances where the tool presetting offline is a key factor in keeping the shop at maximum productivity. Long-Term Flexibility

Dedicated tools for large families of product may be desirable, but consider a changeable adapter system and talk to your supplier before making that determination.

Adjustable angle head systems can be costly, but worthwhile, owing to the stability and rigidity of their construction, when producing families of parts with only slight differences in the dimensions.

Originally Printed Wednesday, October 17, 2012 Modern Machine Shop, Preben Hansen, President, Heimatec Inc. The smarter you are when choosing the live tools for your job, the more efficient your lathe becomes. When any metalworking manufacturing facility, whether captive operation or job shop, makes the substantial investment in a new lathe, it is often looking for ways to streamline the manufacturing process.

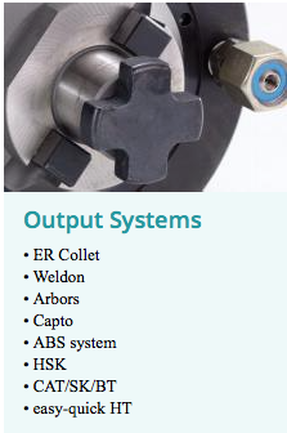

The smarter you are when choosing the live tools for your job, the more efficient the machine becomes. The key is to find a supplier of live tools that offers high-quality, high-performance products that will provide more flexibility on the first big job and into the future. The first tool feature to consider is the output needed. Should that be standard ER output or quick change? Do you need coolant through the tool capabilities? Does the tool meet your requirements for precision and performance, including the necessary torque output to complement the machine? Are the tools designed according to the specifications of the lathe manufacturer? When you look at an ER output, does it give you enough flexibility or do you need a more flexible machining system that will allow you to use the same tool for different applications? If more flexibility is required, then you may want to consider tooling with a system that features adapters for a variety of tools to avoid the cost of new complete toolholder assemblies for each tool needed. However, when you look at such systems, be sure they feature a rigid polygon drive system design to prevent power transmission and alignment issues. Such systems seem appealing, because the live tool stays in place and only the adapter and collet get changed out with each new tool. However, less-sophisticated though inexpensive systems will compromise the accuracy of your work. At that point, the few dollars saved will mean very little, compared to the resulting scrap and downtime. If change-over time is critical, such as when working on a “family of parts,” the option of a true “quick-change system” might be more beneficial. Adapters can be set offline and ready to go for minimal change-over time. When coolant-through tools are selected, it is imperative that you first check the machine specifications to be sure your tool is capable of handling the coolant pressure of the machine. In general, your internal coolant live tools should be able to handle 1,000 psi or more. If your live tool is constructed with large, high-accuracy bearings, the tool will have excellent rigidity and premium cutting performance with minimal runout (0.0002" or 0.006 mm is a desirable goal). The bearings, combined with ground, paired and high-accuracy gears, make for tools that are consistent and long-lasting. Bore tolerance is absolutely key in maintaining proper bearing load and this factor should never be compromised. In addition, you should consider the many applications that can be accomplished with the proper live tool. You can purchase speed increasers for higher rpm, gear reducers for added torque, adjustable angle tools for compound angles, multiple-spindle tools for additional capacity, or gear hobbing tools for spline or gear cutting. While most of those items are standard catalog devices, consider one more piece of advice: Never shy away from the custom tool, when appropriate and justified by the job you have in-shop today, as well as the ones you might have tomorrow. A good tooling supplier will work with you to produce custom tools at reasonable prices, but the supplier must be very reliable, so look for one with grinding, finishing and perhaps even heat treating in-house or very closely monitored, to do such work. Additionally, be certain the supplier has local support and tools can be repaired or reworked quickly and correctly. The workpiece materials are always a driver. Those of you doing medical machining know this well. Buying a less expensive tool or one with fewer features to work cobalt chromium and titanium is a really bad idea, to be blunt. On a practical level, always check the supplier for inventory and source of supply. Today, when your customers are demanding faster response times and more cost off-loading, you can expect the same from your tooling supplier. Likewise, application and engineering assistance should be available from local sources to support your tool choices. The bottom line is the bottom line for most of us today. However, always consider the future jobs when purchasing tooling systems for your new and existing lathes. What might seem a bargain might not be, after the first big job is completed. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed