We represent Platinum Tooling Inc. in our entire territory. Platinum Tooling Inc. is a world leader in the development and manufacturing of live tools, angle heads and multi-spindle drill heads.

Platinum Tooling Inc. is the exclusive North American supplier for several premier brands including

Platinum Tooling Inc. is the exclusive North American supplier for several premier brands including

- Heimatec tooling - Live Tools, right angle heads, 1:4 speed multipliers, and multi-spindle drill tools for all major lathes and machine centers

- Henninger - spindle speeders

- QUICK - Hommel + Keller high-end knurling & marking tools

- Rineck - Shrink fit toolholder

- Tecnicrafts Swiss collets and guide bushings

Platinum Tooling Inc.

|

Platinum Tooling's highly qualified and experienced team of engineers and designers is in permanent contact with manufacturers of bearings, high power transmissions, seals for coolant, etc.

This allows them to stay ahead of technical developments and offer customers state of the art live tools, speciality tools and flexible and quick change tool adapter systems. |

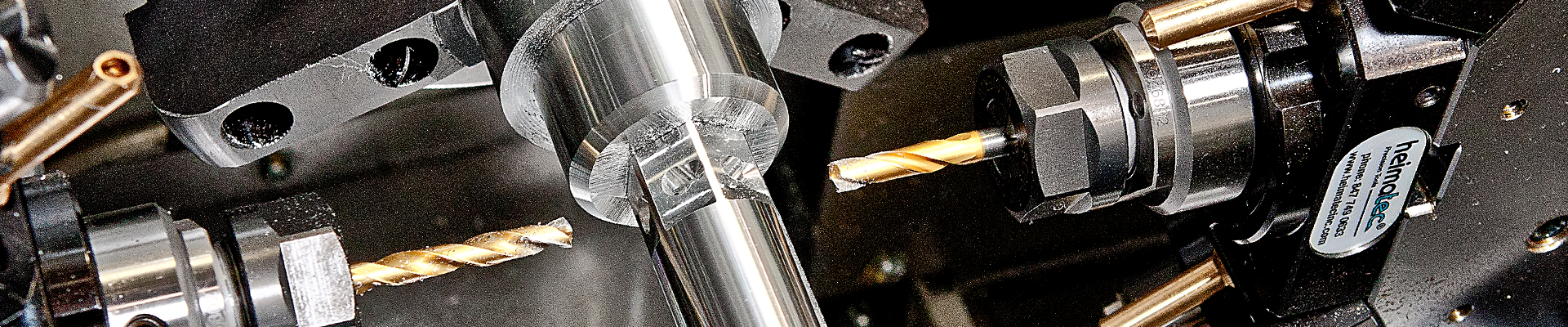

Heimatec Live Tooling & Angle Heads

|

Heimatec has been making tools for CNC lathes for many years

|

|

Live Tooling for CNC Lathes

Their wide product range consists of a comprehensive tooling offering for almost all current CNC lathes. The flexibility and variability of the designs results in a substantially increased production output.

Their tools are suitable for many applications in the field, and their Live Tooling come with a choice of external and internal coolant supply.

Their tools are suitable for many applications in the field, and their Live Tooling come with a choice of external and internal coolant supply.

Angle Heads

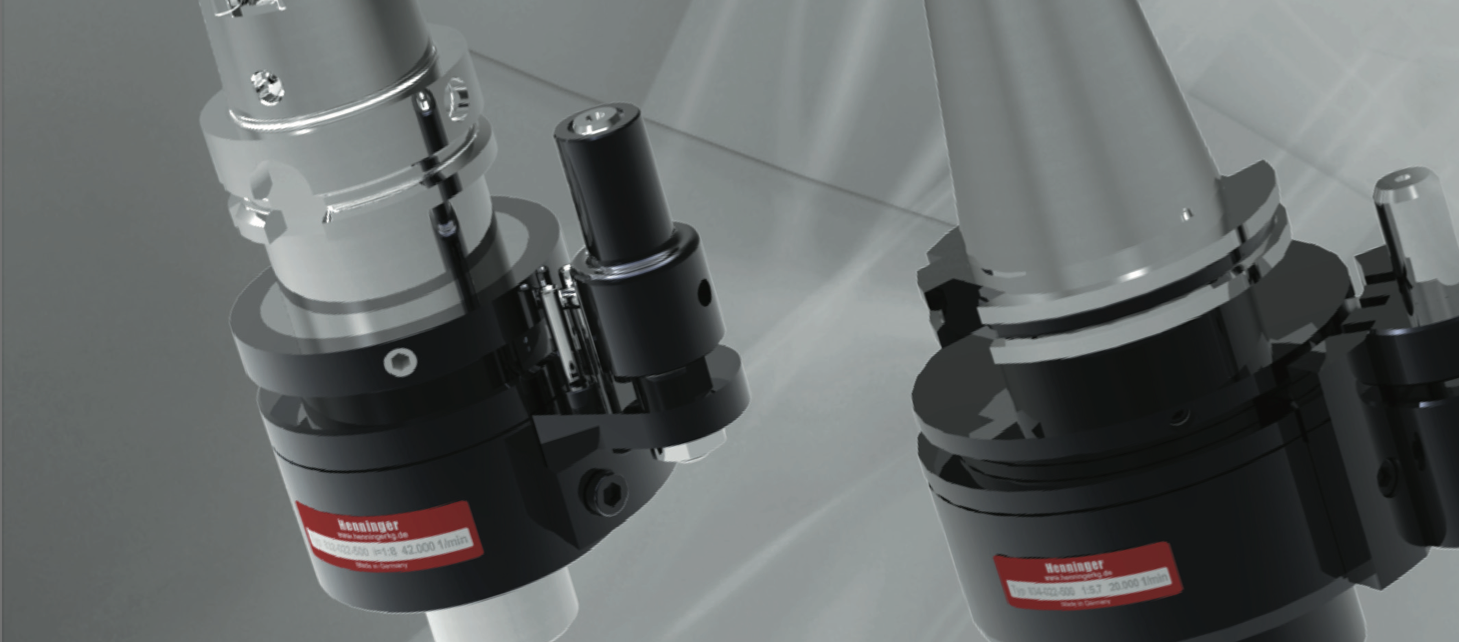

Henninger - Spindle Speeders

Mechanical, air, and electric motor driven Spindle Speeders, Custom Angle Heads and Live Centers are their specialties.

- Henninger Spindle Speed Increasers help maximize productivity with gear ratios of up to 1:8 and speeds up to 50,000 rpm. The tools allow for less wear and tear on the machine spindle.

- Henninger Air Speeders allow for optimum rpm for small tools. Designed for tool shanks up to Ø 7mm (.275”) and can run up to 80,000 rpm continuous.

- Henninger High Frequency Motor Spindles offer a wide variety of products suitable for most high-speed applications

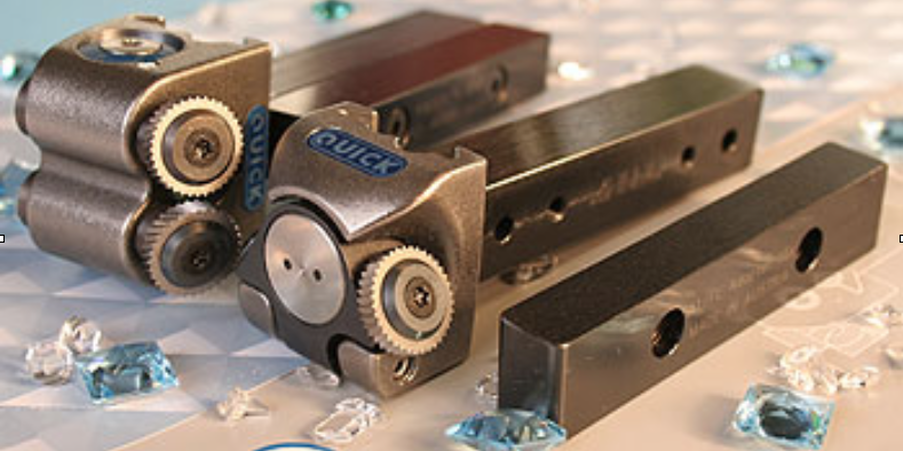

QUICK - Hommel + Keller Knurling & Marking tools

Hommel + Keller, a global leader in high-end knurling & marking tools, manufactures the QUICK brand with a combination of function and innovation. These superior quality tools have a long and proud history with special consideration taken for their customer’s requirements. Quality, precision, and stability are the key principles used in making the QUICK tool technology a success.

Tecnicrafts Swiss Collets and Guide Bushings

Tecnicrafts offers a wide range of Collets and Guide Bushings suitable for most Swiss style machines. All Collets and Guide Bushings are available in standard and ultra-precision grades with a runout accuracy of 5 microns or less. Bore profiles include round, square, hexagon, rectangle, and custom.

Check out the latest BLOGs

on Platinum Tooling Products

Keyway Machining With Unique Angle Head From Heimatec "pins for stabilizing the tool, CAT 50 taper style, 360º indexable pivot on the angle head and inclined tooth gear design for maximum rigidity."

Custom Hobbing Tool Enables 45-Degree Angles

"To machine helical gears at 45-degree angles, Gurecky installed a customized multifunctional machine from DMG Mori Ellison Technologies with a hobbing tool from Heimatec."

"To machine helical gears at 45-degree angles, Gurecky installed a customized multifunctional machine from DMG Mori Ellison Technologies with a hobbing tool from Heimatec."

Getting Started with Live Tools

"The bottom line is the bottom line for most of us today. However, always consider the future jobs when purchasing tooling systems for your new and existing lathes. What might seem a bargain might not be, after the first big job is completed."

"The bottom line is the bottom line for most of us today. However, always consider the future jobs when purchasing tooling systems for your new and existing lathes. What might seem a bargain might not be, after the first big job is completed."

adapter adaptors angle bearings bmt change cnc collet coolant custom designed different drill easy-quick flexibility gear heads heimatec holders ht inserts internal lathes line live machine manufacturing multi multi-spindle operations output pdf possible precision products quality quick special speed spindle standard static statictools system toolholders tools transmission u-tec used vdi

created at TagCrowd.com

last edit 15 Jan 2024

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|