|

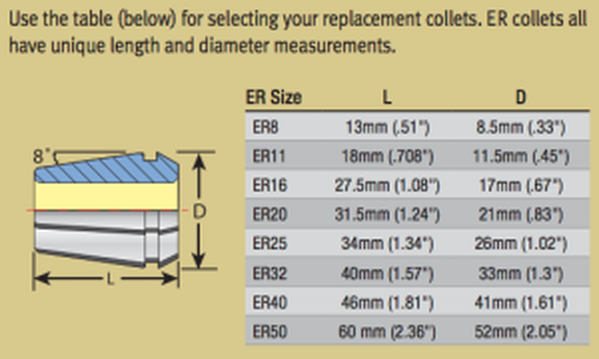

by Bernard Martin ER, IT’S IN THE DETAILS The ER collet system has several advantages when using today's CNC computerized milling machines. The most significant advantage is flexibility to hold any type of round shank tool. An ER collet can be used in drilling, reaming, and tapping as well as milling applications just by exchanging the collet. Its accuracy also provides greater tool life than older style collet systems like TG or DA. Another advantage is the flexibility of the collet for clamping a wide range of tool shanks with a small number of collets. ER 16 through ER 40 provide a collapse range of ~.039" flexibility for clamping cutting tools. This is a benefit for you because you will not have to carry as many collets in inventory for the different jobs you need to do each day. The ER collet also provides more holding power by using two principles.

In addition to mechanical differences, the ER collet is also user friendly. It is a self-extracting collet, which eliminates the need for collet squeezers to extract the collet by any other means than screwing the nut off. This enables the operator to spend time running the machine, not extracting collets. These basic principles allow the ER collet system to be the most widely accepted collet system in the world for holding round shank cutting tools.

ER style collet chucks should be used for the bulk of your needs. They are the most dependable, with the least runout, both in and out of the cut, are readily available (so the prices continue to drop) and will give you the best tool life out of the lot of them. Advantages of the ER Collet System

1 Comment

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed