|

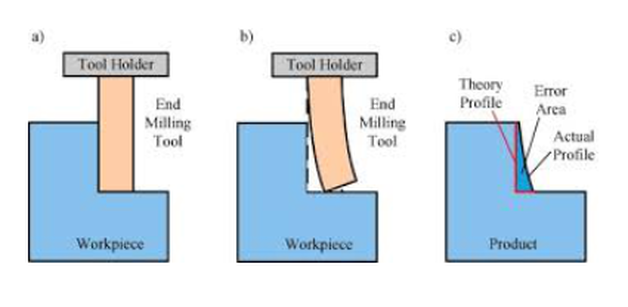

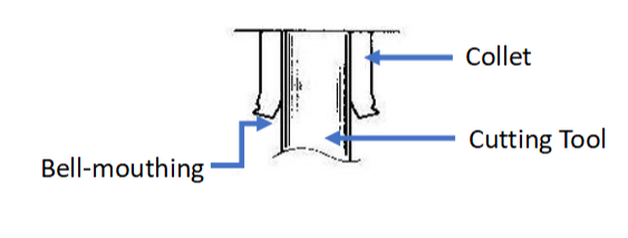

Technical Blog excerpt courtesy of Techniks USA It is important to understand how collets work, what impacts their performance, how to maintain collets for long service life, and how to recognize when to replace them. Collets are a high-precision wear component of a tool holding system and require maintenance to ensure accuracy. First, it’s important to remember that collets are the softest component in a collet-based tool-holding system assembly and are designed to wear out. Here is an overview of the wear pattern of a collet-based tool-holding system. The machine spindle is harder than the tool holder/collet chuck that fits into the spindle, so any wear between these two components will mostly occur to the collet chuck. That’s good. It protects the spindle from expensive maintenance. Collets are softer than both the collet chuck body and the cutting tool, so any wear forces between these items will mostly occur to the collet. Since collets are generally the least expensive component in a collet chuck tool holding system, it is preferred that the collets wear out before the other components. Worn-out collets will not achieve the same level of accuracy and rigidity that newer collets can provide. The result is more chatter when cutting workpieces, less accuracy, and shorter cutting tool life. When to Replace ColletsCollets are designed to wear out as they lose accuracy and rigidity with use. High side-load forces during milling operations cause cutting tool deflection as illustrated below. Over time, these side-load forces will bell-mouth the collet at its face. As the collet experiences bell-mouthing, the cutting tool is allowed to deflect more and more during milling operations. Unfortunately, the collet may still indicate good accuracy on a presetter where there are no side-load forces. However, once the tool is put into service and begins experiencing side-load forces, the cutting tool is allowed more room to deflect, resulting in increased chatter and reduced tool life. It is recommended to change collets out every 4-6 months, depending on usage, to ensure the most rigid and accurate collet chuck assembly. A good rule of thumb is to replace collets every 4-6 months to maximize the performance of your tooling. Again, collets are designed to wear out and are generally the least expensive component in the system. It is much less expensive to replace the collets as opposed to prematurely wearing out cutting tools. The following tips will help you in maintaining collets:

Signs that Your Collet Should be Replaced

If you see signs of fretting on the collet, it is advised to replace the collet. You should also ensure that collet nuts are tightened to the correct torque specifications during setup.

CLICK HERE to see all of our more in-depth articles on FRETTING to learn more.

0 Comments

|

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed