|

About the author: Jack Burley, Vice President of Sales and Engineering and Big Kaiser Precision Tooling Inc. Micromachining, cutting where the volume of chips produced with each tool path is very small, is not a high-speed operation in relation to chip load per tooth. Rather, it involves a high spindle speed relative to cutter diameter. The part may be physically larger, but details of the part require ultra-small profiles achieved only by micromachining. In other words, micromachining is not limited in scope to only miniature parts. TOOLHOLDING In medical work, where tight tolerances are standard, dynamic runout; the measurement of the spindle at high speeds, performed using laser or capacitance resistance technology, and balance must be controlled to deliver and maintain viable tool life.

A holder with 0.00060" runout accuracy produced nearly two-thirds fewer holes, only 800. In this scenario, the shop could save hundreds of dollars a month in carbide costs – as well as labor costs due to less tool changing – by making one smart tool holder choice. Holder attributes that can boost production include symmetrical design, a perfectly concentric collapse of the collet around the cutter, and a ball-bearing raceway nut with precision-ground threads. CHALLENGES While these characteristics are good rules of thumb, things change fast in this field and, like our customers, we must adapt as trends emerge. Batch sizes are getting smaller. Bone screws, for example, were typically run on multi-axis, Swiss-type lathes where the same tools and programs ran for days at a time. Traditionally, prototyping in this arrangement was not an option because of the complexity and time involved in programming and setup. Today’s need for customized sizes demands flexibility and quick changeover to remain productive. We are investing a large portion of our research and development (R&D) in tackling this challenge. We are working on hydro-clamping tool holder systems that could make the decades-long approach of using ER collets obsolete. It would make it possible, for example, to perform a simple drill change on a gang slide in seconds. COOLANTS Another trend in medical manufacturing being driven by the U.S. Food and Drug Administration (FDA) is clean machining without the use of water-soluble coolants.

We are focusing on two features:

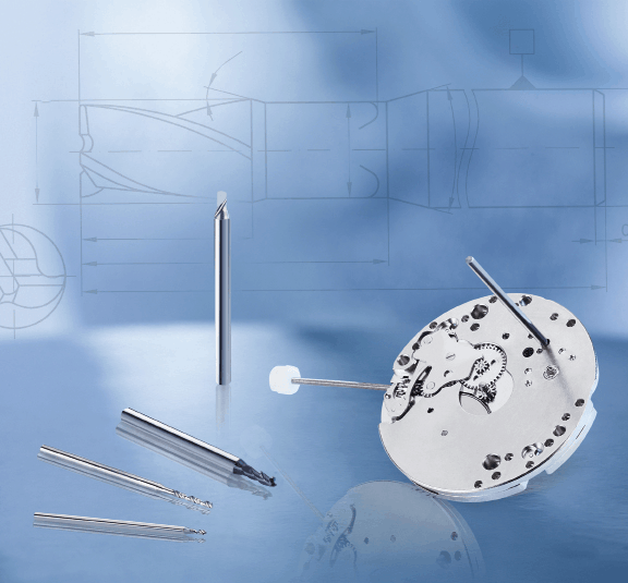

TOOLING Tool considerations also must be taken into account to keep up with the demanding medical field. Better results often cannot be achieved by simply increasing spindle speeds or using smaller tools; a deeper understanding of cutters is necessary. We consider tools with diameters <3mm to be micro tools. These aren’t simply smaller versions of their macro counterparts. They have geometric considerations all their own. For example, the 1mm Sphinx drill can run at 80xD. But this is only possible because the cylindrical shaping extends further down the tool, closer to the tip, to facilitate pecking and maintain strength. Tool carbide should be ultra-fine grain (nano or submicron grain size) to ensure high abrasion resistance and good toughness. Coatings are valuable too, but it’s important to understand how coatings can negatively impact micro tool performance. Micro tools have extremely fine surface finishes and sharp cutting edges. Coatings can fill in valuable space – a flute on a drill, for example – needed for proper chip evacuation, which is critical in these applications. Coatings must be ultra-thin (<1µm) and smooth; our experience shows that misapplied coatings result in poor tool life due to breakage; the coating reduces cutting edge sharpness, increasing torque force on the drill. When coating is necessary, consult with the cutting tool manufacturer to provide this directly. Chips and small tooling naturally do not get along well. Compensating for low spindle speeds with tools that have more flutes support an ideal feed rate, but chip evacuation may suffer. Determining the appropriate chip load – as close to the cutting edge as possible – allows operations at the highest possible spindle speed, accelerating the cycle and improving surface finish. Optimal conditions exist when the chip load is relatively equal to the cutting edge radius. Many micro end mills are designed so the cutting edge radius has a positive rake angle to create a shearing action. A chip load less than the cutting edge radius often results in a negative rake angle where the tool rubs rather than cuts. This increases the force required and generates more heat which can result in built-up edges and poor tool life. A chip load significantly bigger than the cutting edge radius often leads to premature failure because the tool is not robust enough to withstand such forces. MACHINE TOOLS

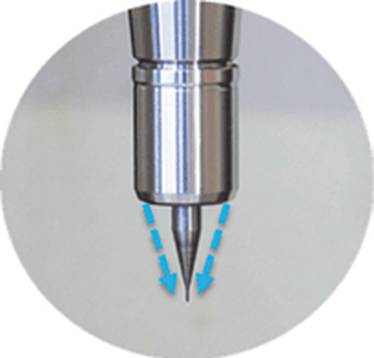

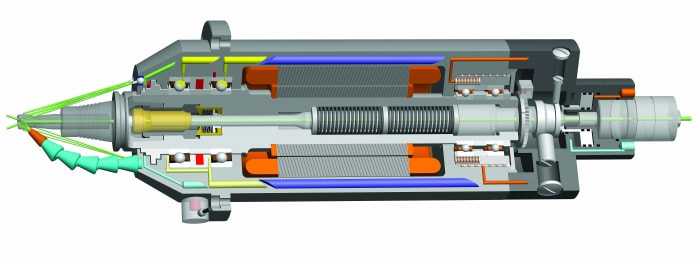

Micromachining requires machine tools with very high sensitivity, fine resolution in the feed axis, and very precise spindles capable of high speed with low dynamic runout. For micro-drilling operations, specialized micro machines are best. Micro milling machines are suited for small tools and small workpieces. They are characterized by spindle speeds faster than 50,000rpm using small HSK tool holders such as HSK-E32, E25, or E20. With the right holder, tool runout can be controlled to less than 1µm (0.000040") at the cutting edge, ensuring sub-micron accuracy. In medical micromachining, understanding each piece of the equipment puzzle is critical. It’s also important not to make assumptions based on other tools or parts you may have worked with, especially in more standard sizes. Invest the right time and energy in gearing up for the next medical job and you’ll get more parts done right faster.

1 Comment

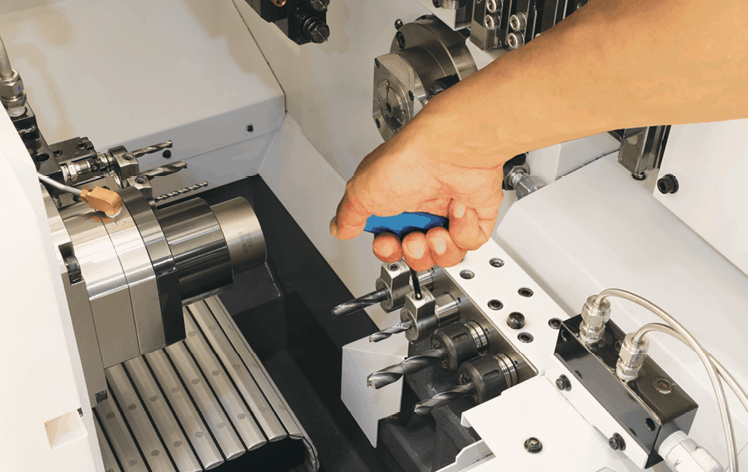

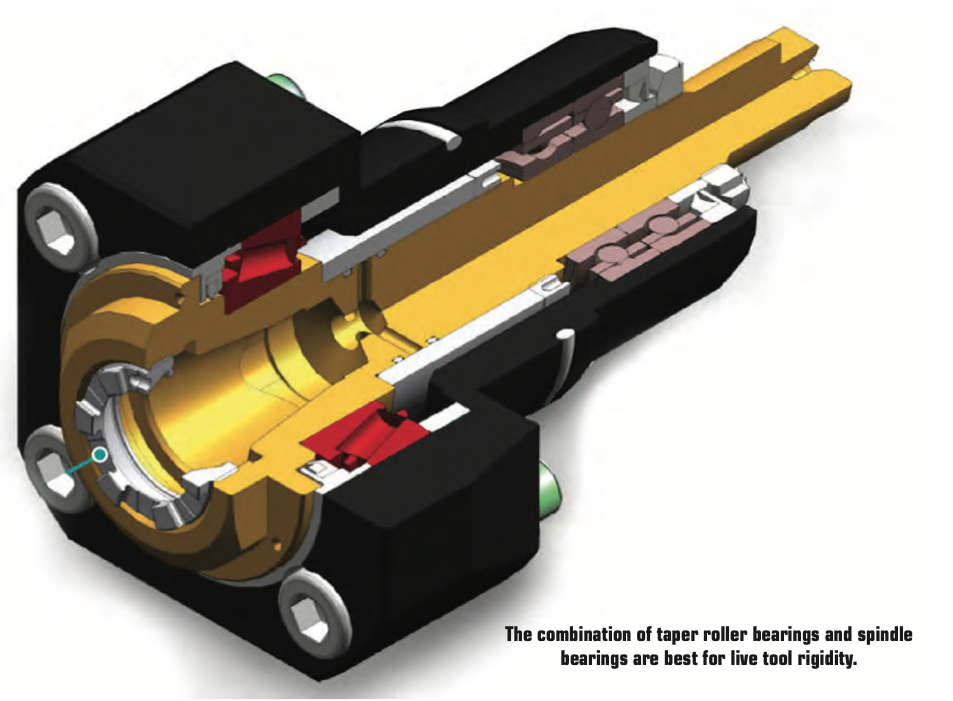

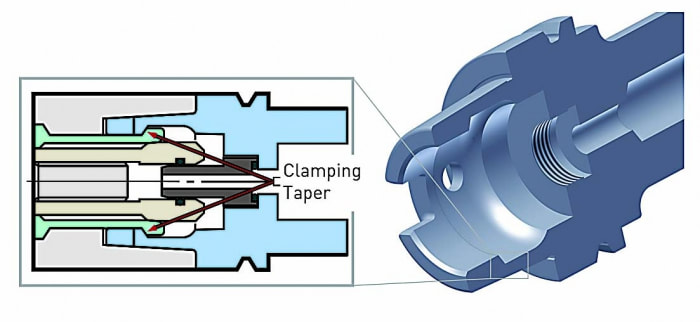

A REVIEW OF THIS MACHINING METHOD, THE BASIC CONCEPTS AND SOME EXCITING DEVELOPMENTS IN THE TECHNOLOGY by Preben Hansen, President, Platinum Tooling Technologies Inc. Live tooling, as a component on a lathe, is specifically manipulated by the CNC to perform various milling, drilling and other operations while the workpiece is being held in position by the main or sub spindle. These components, whether BMT or VDI, are also called driven tools, as opposed to static tools, that are used during turning operations. All live and static tools are built per the machine tool builder’s specification for each of the various models they produce. A key to running a successful job shop or production department is to partner with a supplier who can meet the tooling needs for all or most of the machines on your floor. Most often, live tooling is offered in standard straight and 90º angle head configurations with a wide range of tool output clamping systems, including ER collet chuck, arbor, Weldon, Capto, whistle notch, hydraulic, HSK, CAT, ABS and a variety of custom or proprietary systems developed by the many suppliers to the industry. When the need arises for a new machine tool, careful consideration should be made to determine which live tools are appropriate for your application. While a standard machine tool package will help you get started, it is important to anticipate job and volume changes, as well any unforeseen machining challenges from the beginning, in order to avoid machine downtime. This short article is meant to give you a set of parameters to consider when evaluating the live and static tooling to use in your shop or production department. Simply stated, you need to do as much evaluation of your process, when determining the proper tooling to be used, as you did when you evaluated the various machines available for purchase. This fact is often overlooked and that can be a critical error, in the long run. Your examination can range from the simple (external vs. internal coolant, for example) to the sublime (adjustable or multi-spindle configurations) to the custom tool, that may be required and built to suit your special application. Finding a supplier who has an in-house machine shop for the preparation of special tools is a great value-add. Tool life is the product of cutting intensity, materials processed, machine stability and, of course, piece parts produced. Two seemingly identical job shops can have vastly different tooling needs because one is automotive and one is medical, or one specializes in the one-off and low-volume work, while the other has a greater occurrence of longer running jobs. The totality of your operation determines the best tooling for the machines being purchased. Bearing construction and the resulting spindle concentricity drive the life of any tool. You might find that just a 10-15% greater investment in a better design can yield both longer lasting cutters and consistently superior finish on your products. Of course, the stability and rigidity of the machine tool are always critical factors. Bevel and spur gears that are hardened, ground and lapped in sets are best for smooth transition and maximum torque output. Taper roller bearings are consistently superior to spindle bearings in live tool milling applications, so look for a combination system to get the highest rigidity possible. Also, look for an internal vs. external collet nut, so the cutting tool seats more deeply in the tool, as superior performance will result. Likewise, high pressure internal coolant might be desirable. Look for 2000 psi capabilities in 90º tools and 1000 psi in straight tools.You need to ask another question, namely, is the turret RPM sufficient to handle the work to be done? It’s possible that a live tool with a built-in speed increaser, often called a speed multiplier, would be helpful. Would it be beneficial to move secondary operations to your lathe? Gear hobbing can be accomplished in this manner, as can producing squares or flats, through the use of polygon machining. Standard live tooling most often is best suited to production work, where the finish, tolerances and cutter life are critical, while quick-change systems may be better suited to the shop producing families of products and other applications where the tool presetting offline is a key factor in keeping the shop at maximum productivity. It’s a given in our industry that when the machine isn’t running, the money isn’t coming.

Dedicated tools for large families of products may often be desirable for some applications, but do consider whether a flexible changing system would be more appropriate. Talk to your tooling supplier for the various options, before making that determination. If standard ER tooling is suitable for the work, there are many good suppliers. It is important though, to pay close attention to the construction aspects noted above. For a quick-change or changeable adapter system, there are fewer suppliers in the market, so seek them out and be sure they can supply the product styles you need for all your lathe brands. Now, an application example showing clear evidence of the value of testing live tool performance... One company was performing a cross-milling application using an ER 32 output tool on a Eurotech lathe, running 10 ipm at 4000 rpm. They were making three passes with a cycle time of 262 seconds and were having difficulties with chatter on the finish, while producing 20,000 pieces per year. The annual cost of the machining was over $130,000. By using an alternative live tool with an ER 32AX output, internal collet nut design, with the same parameters, they were able to produce the part in a single pass with a smooth finish and cycle time of just 172 seconds. Over the course of the year, this yielded a cost savings of $45,000, approximately 20x the cost of the tool. The bottom line is the bottom line, as the accountants tell us. In the end, you may not need a universal adjustable tool or a multi-spindle live holder or even a quick-change adapter system but do consider all these options. Talk to your machine builder and several tool suppliers, plus the most important people in this equation, your shop personnel, as their input is invaluable to keeping you up and running in a profitable, customer-satisfying scenario. The author welcomes questions, comments and additional input from readers. Please contact Preben Hansen at 847-749-0633 or phansen@platinumtooling.com. Mr. Hansen has over 30 years in tooling and is considered a leading authority on the topic in the North American machine tool market.

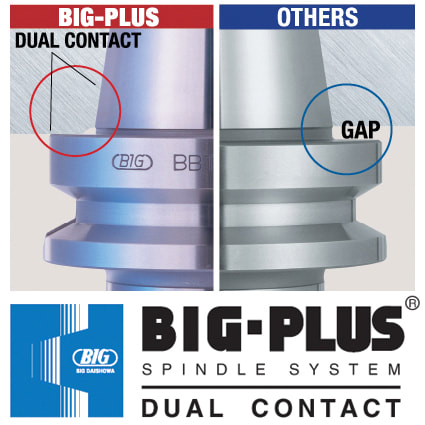

Below are excerpts from a Cutting Tool Engineering article by the same title. To read the entire article please click HERE.  Author Kip Hanson, Contributing Editor, Cutting Tool Engineering (520) 548-7328 [email protected] Kip Hanson is a contributing editor for Cutting Tool Engineering magazine. Originally Published: September 12, 2017 - 3:00pm Shopping for a machining center was simpler when buyers had only two basic spindle choices: CAT or BT. Both of these “steep tapers” have an angle of 3.5 in./ft., or 7" in 24" (7/24), and are based on the 1927 patent by Kearney & Trecker Corp., Brown & Sharpe Manufacturing Co. and Cincinnati Milling Machine Co. With the development of automatic toolchangers in the late 1960s, machine tool builders in Japan modified the patented design and invented the BT standard. In the 1970s, tractor manufacturer Caterpillar Inc., Peoria, Ill., changed things again with a flange design now known as CAT, or V-flange. “Sticking” TogetherDuring the late ’80s, machine tool builders began offering vertical and horizontal CNC mills with spindle speeds higher than the 6,000 to 8,000 rpm common at the time. As rpm increased, so did problems with steep-taper toolholders. Chief among them is the tendency for the mating spindle and toolholder tapers to stick together. This is caused by the expansion of the spindle housing at high speeds, which allows the toolholder to be pulled upward into the spindle taper, jamming it in place. HSK spindles, like the one shown in the illustration below, offer advantages steep-taper styles can't. One way to eliminate this problem is by extending the toolholder flange upward, thus creating a hard stop against the spindle face and preventing further Z-axis movement. This is the approach taken by BIG KAISER Precision Tooling Inc., Hoffman Estates, Ill. Jack Burley, vice president of sales and engineering, said the BIG-PLUS system—developed in 1992 by BIG Daishowa Seiki Co. Ltd., Osaka, Japan—relies on a bit of elastic deformation in the spindle to provide dual points of toolholder contact at its face and taper, eliminating upward holder movement as the spindle expands. He said it’s also more rigid, with tests showing that the deflection on a CV40 BIG-PLUS toolholder measured at 70mm (2.755") from the spindle face is only 60µm (0.002") when subjected to 500kg (1,102 lbs.) of radial force, roughly half that of a traditional V-flange toolholder. “There are now roughly 150 machine builders that either offer BIG-PLUS or have it as a standard,” Burley said. “The beauty of the system is that it can use either standard toolholders or BIG-PLUS interchangeably. So for drilling and reaming work, you can use a conventional collet chuck, but for heavy milling cuts or profiling operations at higher spindle speeds, BIG-PLUS improves accuracy and tool life.” Revving UpBurley does not recommend BIG-PLUS for older machines that have never seen these toolholders, because CAT and BT taper-only contact holders tend to bellmouth the spindle over time, leading to undesirable results. BIG-PLUS, like any dual-contact toolholder, requires particular attention to cleanliness, as chips caught between the spindle face and the toolholder can cause serious problems. He also recommends staying below 30,000 rpm when using 40-taper holders, noting that higher speeds are better handled by HSK spindles and holders. Keep It CleanBill Popoli, president of IBAG North America, North Haven, Conn., said the company started building steep-taper spindles in the late ’80s, but 95 percent of its work has since transitioned to HSK spindles. As mentioned earlier, the extreme accuracy needed to guarantee near-simultaneous contact between the spindle face and taper is challenging, requiring micron-level tolerances in toolholder and spindle alike. These requirements were impossible to meet when steep taper was first developed, Popoli said, resulting in looser standards overall for CAT and BT spindles than the ones applied to HSK spindles and toolholders. Because of this, purchasing an HSK or equivalent toolholder automatically makes one “part of the club” when it comes to balance, accuracy, repeatability and tool life. That’s not to say, however, that shops firmly married to steep tapers should settle for less. Popoli recommends purchasing the highest-quality tooling possible and paying close attention to the stated tolerance.

Always stay below 20,000 rpm with 40-taper holders, and reach no more than 30,000 rpm with 30-taper ones. Use balanced holders and high-quality retention knobs that have been properly torqued—otherwise distortion at the small end of the taper may occur. And whatever the taper type, keep the spindle and toolholder clean at all times. Bob Freitag agreed. The manager of application engineering at Minneapolis-based metalworking products and services provider Productivity Inc. said the lines are evenly split between traditional 40- and 50-taper CAT or BT tooling (much of which is BIG-PLUS) and HSK. “It really depends on the application,” Freitag said. “Most of our die and mold machines in the 20,000- to 30,000-rpm range will have an HSK63A or HSK63F. When you get up around 45,000 rpm, you’re probably looking at an HSK32. But in horizontal machining centers and lower-rpm, high-torque verticals, you’ll see mostly steep tapers, as this is generally preferred for deep depths of cut and lower feed rates, where you’re removing a lot of material at once.” For shops that want to make the leap to an HSK machine but are leery of investing in new toolholders, Freitag advised: “Anytime you buy a new machine, you should buy new toolholders to go with it. If not, the imperfections of the old toolholders will soon transfer themselves to the spindle on the new machine.” |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed