|

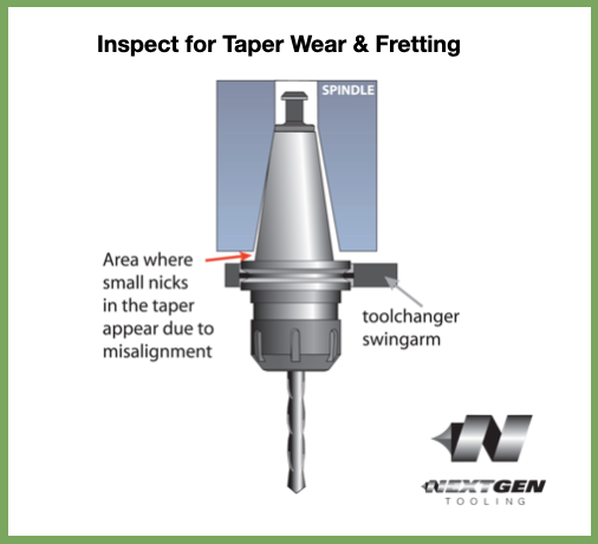

A worn out toolholder will not provide good accuracy and will quickly wear out your cutting tools. Worn tooling can also cause poor surface finish, and may even damage your spindle. Learning where to look and what to look for will alert you to potential problems before they become catastrophic. Taper Wear & FrettingCheck the taper for signs of wear or damage where it contacts the spindle mouth. Any problems with the taper will have a direct effect on machining accuracy. If there are any imperfections on the taper, the toolholder should not be used.

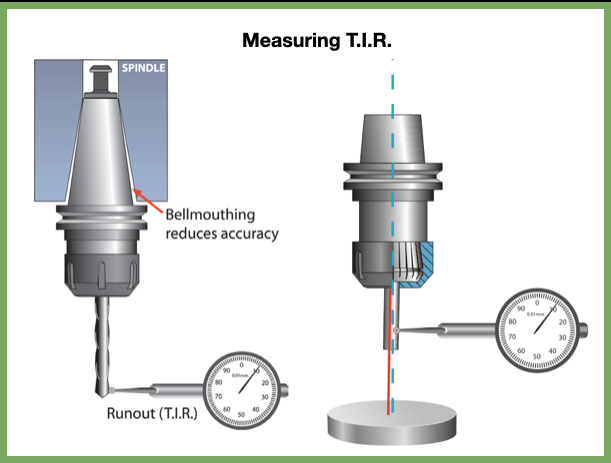

Fretting is caused by imperfect mating between tooholder taper and spindle, creating vibration and heat which develops the fretting. It is visible as small copper colored pits or marks on the taper. This is evidence that the toolholder is becoming worn. Fretting is easily mistaken for rust, but it is not. Once noticeable fretting develops the toolholder should be replaced. New toolholders that quickly develop fretting, or toolholders that stick in the spindle, may indicate a spindle that needs to be reground. A worn taper causes an out-of-round condition when the holder is inserted into the spindle. This is called “runout”. Runout causes premature tool wear and excessive vibration during operation. This vibration can cause poor surface finish which may require additional operations to correct. Vibration can also cause heat build-up in the spindle and damage spindle bearings. See our video below to learn how to check toolholder T.I.R. “How to check Runout”. This video will help you learn how to check runout (total indicator runout or T.I.R.) to check your CNC machine tool holders performance.

Good T.I.R. (less than .0002") keeps cutting tools cutting smoothly and prevents cutting tools from wearing out prematurely. Tool holders do wear out over time and if good T.I.R. cannot be achieved either the collet, nut, or holder may need replaced.

0 Comments

Leave a Reply. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed