|

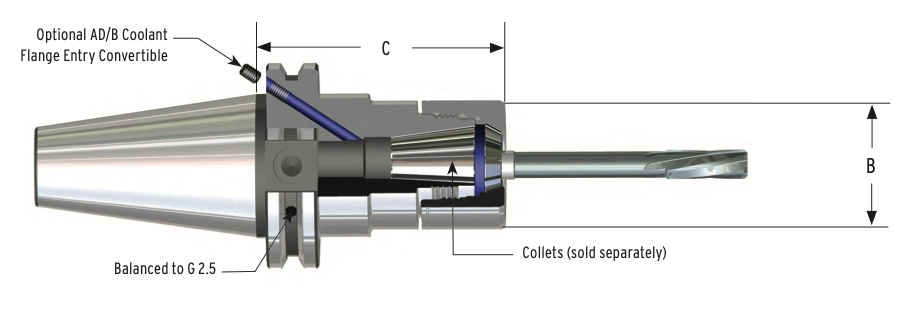

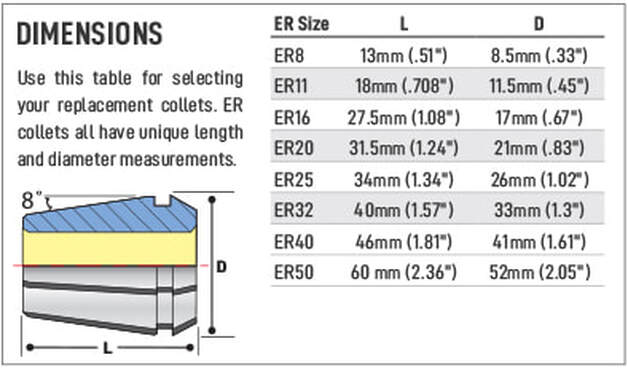

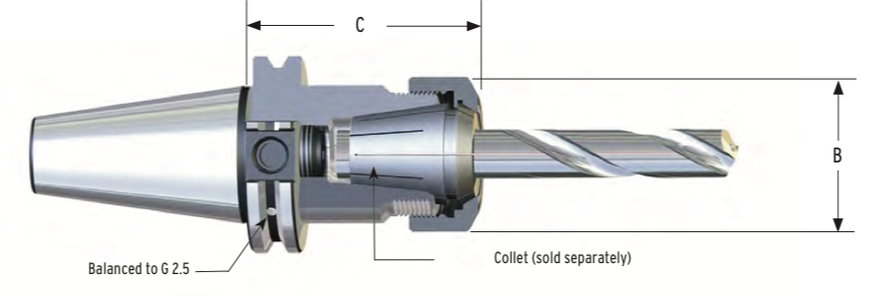

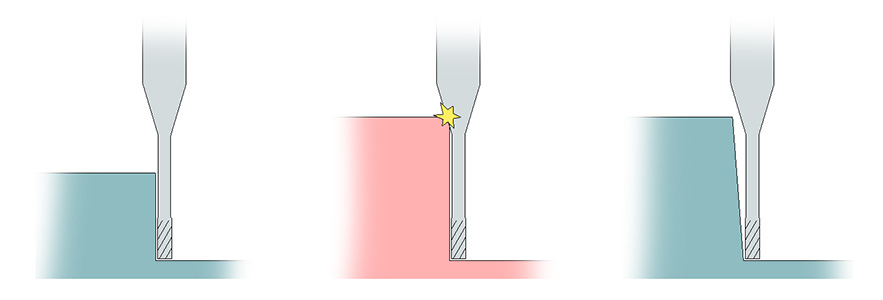

We often get asked to spec out tooling packages for new CNC mills and one of the questions we encounter most, or should, is how do you select the right toolholder collet size for your companies applications? The real choice is in the size of the collet chuck itself. So several considerations should be reviewed... What size are your tools?Your first consideration should be the size of end mills or drills you will be using most often. If you are doing smaller work you would require smaller diameter range collets. Generally you may prefer the ER16 and ER32 sizes. If you are doing very small work then perhaps an ER11 set would be the best choice. If the bulk of your tool requirements are in the mid range you can also use the ER20. The following is a list of tool diameters that can be used with each size collet chuck. Essentially, the most popular, and again, readily available from a number of sources, are the ER 16, ER20, and ER32... in no particular order. If you need more detailed list of dimensions can be found at these links: How far do you need to reach?A second consideration is the actual reach of the tool. Not projection reach, also know as “gage length” "l1" but projection diameter “D”. Obviously, stubbier is better for projection reach "L1". But, you also need to review the families of parts that you intend to run on the machine. If you intend to use the holder to "reach" into a tight fit then the OD of the projection "D" of the toolholder needs to be considered. Many shops don't always consider this and end up using much longer carbide shanked end mills to get into deep pockets when getting a smaller diameter ER collet and collet chuck would be much less expensive over the life of the job. Here is a list of the OD projection diameters:

Sometimes there is just no getting around having a custom tool made. Get in contact with us if you just can't seem to reach into the part with your toolholder.

2 Comments

john

4/27/2024 10:04:11

hello I have an older Hitachi M8 router and need to find a replacement collet and nut for the machine. How do I go about this?

Reply

Leave a Reply. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed