|

by, Preben Hansen is President of Heimatec Inc. Live tooling is driven by the CNC control and the turret of various spindle and powered sub-spindle configurations on CNC lathes to perform various operations while the workpiece remains in orientation to the main spindle. These devices, whether BMT or VDI, are also called driven tools, as opposed to the static tools used during turning operations and are usually customized for the particular machine tool builder’s turret assembly. A common error is often made by accepting the standard tooling packages provided by the builder. This is not a criticism of the standard packages from builders, but this article is meant to give you a set of parameters to consider when evaluating the tooling and toolholding devices to use in your shop or production department. Do as much evaluation of your process, when determining the proper tooling to be used, as you did when you evaluated the various machines available for purchase. Identical Job, Different Tooling RequirementsTool life is the product of cutting intensity, materials processed, machine stability and, of course, piece parts produced. Two seemingly identical job shops can have vastly different tooling needs because one is automotive and one is medical, or one specializes in the one-offs and low-volume work, while the other has a greater occurrence of longer run jobs. The totality of your operation determines the best tooling for the machines being purchased. Bearings & Gears Bearing construction and the resulting spindle concentricity drive the life of any tool and you might find a 10-15 per cent greater investment in a better design can yield longer lasting cutters and consistently superior finish on your products.

Coolant, RPM & 2nd Op Considerations Also look for an internal vs. external collet nut, so the tool seats more deeply in the tool, as superior rigidity will result. Likewise, coolant high pressure might be desirable. Look for 2000 psi in 90o and 1000 psi minimum in straight tools. Standard live tooling is best suited to production work, where the finish, tolerances and cutter life are critical, while quick-change systems may be better suited to the shop producing families of products and other instances where the tool presetting offline is a key factor in keeping the shop at maximum productivity. Long-Term Flexibility

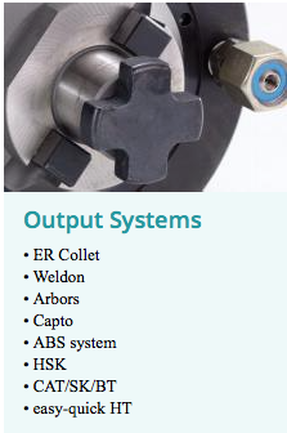

Dedicated tools for large families of product may be desirable, but consider a changeable adapter system and talk to your supplier before making that determination.

Adjustable angle head systems can be costly, but worthwhile, owing to the stability and rigidity of their construction, when producing families of parts with only slight differences in the dimensions.

2 Comments

6/5/2020 05:09:58

I didn't realize that there were so many different tools that can be used for one job. As you mentioned, the custom spindle can be so different depending on if it is a long time use, or a one-off. I will have to keep this in mind if I am ever needing custom spindles in the future.

Reply

7/7/2020 01:09:22

I appreciate that this post encouraged us to always check the package when we receive as it is a common mistake for some packages to be faulty or missing a few things when purchasing live tooling. The other day my brother mentioned that he would like to own a live tooling kit. I will remind him to check the package when he receives it.

Reply

Leave a Reply. |

Technical Support BlogAt Next Generation Tool we often run into many of the same technical questions from different customers. This section should answer many of your most common questions.

We set up this special blog for the most commonly asked questions and machinist data tables for your easy reference. If you've got a question that's not answered here, then just send us a quick note via email or reach one of us on our CONTACTS page here on the website. AuthorshipOur technical section is written by several different people. Sometimes, it's from our team here at Next Generation Tooling & at other times it's by one of the innovative manufacturer's we represent in California and Nevada. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed