|

Hoffman Estates, IL – For the second year in a row, customers who choose best-in-class cutting tools, tool holders and workholding products from BIG DAISHOWA will support their local manufacturing training programs at the same time. From October 1–December 29, 2023, BIG DAISHOWA will once again donate a tooling certificate valued at 20 percent of every qualifying order to the buyer’s school of choice through the Tools for Schools program. Schools can redeem certificates for any BIG DAISHOWA product, including best-in-class tool holders, boring tools, cutting tools, workholding products and presetters. Last year’s program was a resounding success! BIG DAISHOWA issued nearly $30,000 in tooling certificates to high schools, vocational schools, colleges and universities. According to Jack Burley, President/COO of BIG DAISHOWA, it’s all in line with the company’s overall mission to support a new generation of skilled workers. “We are committed to workforce development. This program allows our customers to support local communities by providing their future workforce with the same tools they use in their shops,” said Burley. To participate in the program is as simple as 1-2-3:

Burley says that every dollar spent helps students develop skills they can apply in their careers. “By using BIG DAISHOWA tooling in school, students gain experience with the same tools they will use as future engineers and machinists.” BIG DAISHOWA offers nine product lines of precision tooling, workholding, and tool management systems aimed at reducing both the overall process time and the cost per part. Popular products include face mill holders, end mill holders, collet chucks, angle heads and tapping adaptors. The world-leading KAISER Boring System, high-performance Sphinx Drills and UNILOCK Workholding systems are also available, as are CAT, BT, HSK and BIG Capto systems. If your machine is equipped with a BIG-PLUS spindle, remember that BIG DAISHOWA is the officially licensed provider of BIG-PLUS tool holders in North America. Don’t accept any substitute dual-contact products on your valuable machines. About BIG DAISHOWAAs a member of the BIG DAISHOWA Group (Osaka, Japan), BIG DAISHOWA Inc. is a recognized global tooling provider, with manufacturing facilities in North America, Switzerland and Japan. BIG DAISHOWA is also the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system

0 Comments

Hoffman Estates, IL – Choose best-in-class cutting tools, tool holders and workholding products from BIG DAISHOWA and support your local manufacturing training programs at the same time.

From November 1 to December 30, 2022, BIG DAISHOWA will donate a tooling certificate valued at 20 percent of every order from an NTMA member company to the buyer’s school of choice. “This is a way for us to support our partners and customers in the NTMA and continue to show our commitment to workforce development,” said Jack Burley, president & COO of BIG DAISHOWA Americas. “When buyers select their favorite local school programs, they are sending resources to train their own future machinists and engineers.”

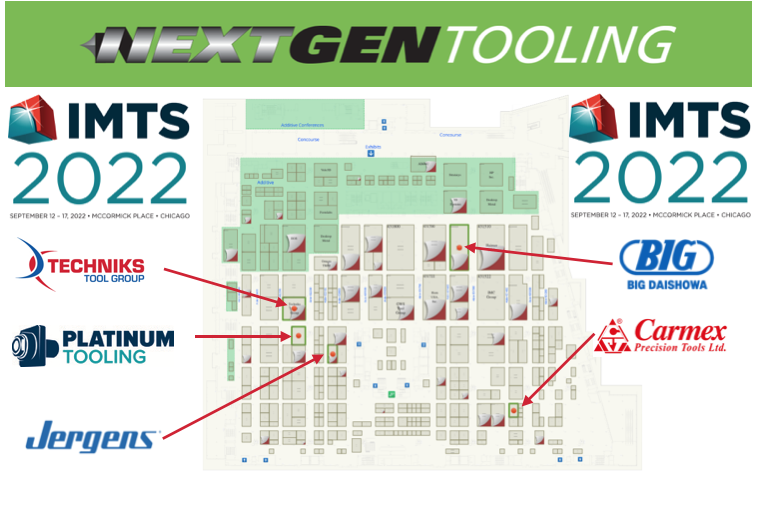

“We’ve been active in NTMA for many years. Our objective is to advise members on applying technology to reduce set ups and cycle times, improve part finishes, and lower costs through longer tool life. I hope this special promotion will be an incentive for those who have not tried our products yet,” Burley said. BIG DAISHOWA offers nine products lines of precision tooling, workholding, and tool management systems aimed at reducing both the overall process time and the cost per part. Popular products include face mill holders, end mill holders, collet chucks, angle heads and tapping adaptors. The world-leading KAISER Boring System, high-performance Sphinx Drills and UNILOCK Workholding systems are also available, as are CAT, BT, HSK and BIG Capto systems. If your machine is equipped with a BIG-PLUS spindle, remember that BIG DAISHOWA is the official licensed provider of BIG-PLUS tool holders in North America. Don’t accept any substitute dual contact products on your valuable machines. As a member of the BIG DAISHOWA Group (Osaka, Japan), BIG DAISHOWA Inc. has grown into a recognized global tooling provider, with manufacturing facilities in North America, Switzerland and Japan. In addition, BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high-performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system. Here's a look at some of the new products and special offers from our manufacturers! You'll want to check them out in-person at the show, on-line during the show or contact us and we can stop in and get into the details at your shop with one of our guys. BIG DAISHOWA High-Performance Tooling SolutionsBIG DAISHOWA designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, military, aerospace, energy, and micro-technology industries. BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system Be sure and check out the two special offers:

Carmex Precision Tools, LLCCarmex Precision Tools specializes in carbide cutting tools for thread turning & thread milling. They will be showcasing a full line of tools for Swiss machines, including turning, back turning, grooving & parting. Jergens, Inc.Jergens Inc is a global manufacturing leader of CNC machining custom workholding products. Today, you'll find their vises, clamps & fixturing systems, tooling components, at work in just about every segment of the metalcutting industry. Check out their innovative engineered solutions like the patented

Platinum ToolingPlatinum Tooling has been hard at work searching to find the highest quality machine tool accessories in the market…and we think they’ve done it! Platinum Tooling will be showcasing the following products at IMTS:

Techniks Tool GroupTechniks Tool Group (TTG), the parent company of Techniks and Parlec, is one of North America’s largest providers of best-in-class tooling solutions for CNC machining centers. Check out the complete list of products they will be demonstrating at IMTS:

PLEASE NOTE: Its a direct result of this announcement we have made some navigation changes on our website to redirect Big Kaiser to BIG Daishowa which has resulted in renaming both their TOOLING page and WORKHOLDING Page URL. All of the information and articles written about Big Kaiser is still here on our website, albeit the actual URL in your bookmark may have changed. The hot links above will take you to the updated information. Hoffman Estates, IL - BIG KAISER Precision Tooling Inc. is excited to share important news concerning the name of its company. BIG KAISER Precision Tooling Inc. will change its name to BIG DAISHOWA Inc., effective January 1, 2022.

“BIG DAISHOWA is a global leader of tooling systems, and we have been a member of the BIG DAISHOWA group of companies for many years,” said Jack Burley, President & COO. “The name change is a natural evolution in this relationship. Being known as BIG DAISHOWA in North America will strengthen our corporate presence on a global scale. “Our customers won’t notice any change in our business day-to-day,” Burley said. “They will receive the same superior products, personal support and performance guarantee we’ve been delivering for more than 30 years.” The name change will not impact operations, product lines, staff, distribution or licensing agreements in North America. The company will continue to offer the same high-precision tool holders, cutting and boring tools, workholding, tool measurement systems and accessories manufactured in Japan, Europe and the United States. As a member of the BIG DAISHOWA Group (Osaka, Japan), BIG DAISHOWA Inc. has grown into a recognized global tooling provider, with manufacturing facilities in North America, Switzerland and Japan. In addition, BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system. Hoffman Estates, IL – BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, introduced Hydraulic Chucks for Swiss lathes in 2018, the first improvement to the technology in more than 30 years. This year, the program has expanded to include inch-size Standard Type chucks, as well as new F Type and R Type chucks.

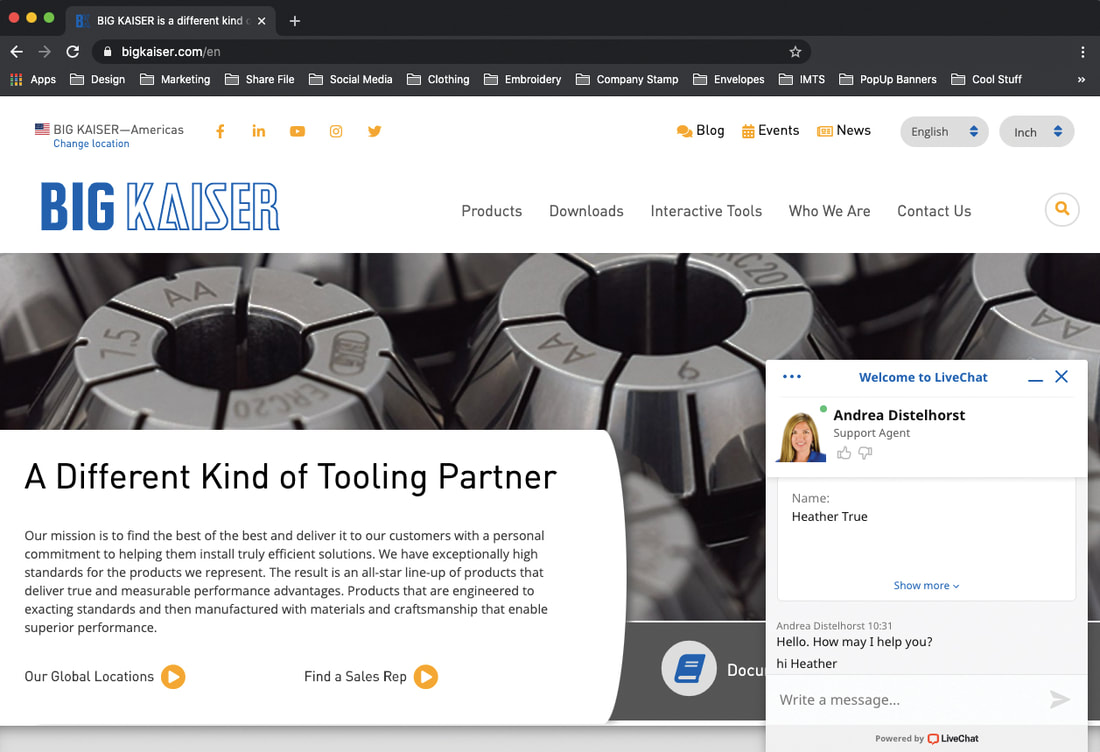

Standard Type Hydraulic Chucks with tool-side clamping are now available in inch sizes with the clamping range of ø1/8”, 3/16” and 1/4”. The new F Type’s single wrench enables easy cutting tool changes on the tool post. The easy-access rear clamping design is ideal for front tool post. Clamping from the opposite side of the cutting tool and optimum-length design improves overall ease of use. The F Type is available in a clamping range of ø3-10mm and coolant delivery is possible with an Rc(PT)1/8’’ screw. The new R Type eliminates interference at both the upper or lower tool post positions with a unique block design and tightening at an offset position in the tool side. The R Type is available in a clamping range of ø3-10mm and its oil hole drills can be used for coolant delivery when mounted on the upper section. To minimize machine downtime and provide operator safety, these Hydraulic Chucks use a simple hex wrench that requires only two to three turns for both clamping and unclamping. Tightening is complete when the clamping screw hits the bottom; controlling tightening torque is not needed. Once a Hydraulic Chuck is centered, the runout will not vary, even if a cutting tool is changed repeatedly. Runout of fewer than three microns at four times diameter can be achieved. Hydraulic Chucks have a standard pipe thread for coolant-through connection and are available for most Citizen and Star machines with 3/4'’ or 22mm straight shank. Hoffman Estates, IL – In order to help current and future customers with their inquiries, BIG KAISER Precision Tooling has introduced an easy and convenient way to directly access the company’s experts. LiveChat is available now on BIGKAISER.com.

No matter which page a customer is on, you can connect directly and instantly with one of the company’s agents in just a few clicks. Agents will be available during normal business hours and customers can leave a message after hours for help with questions on topics such as: • Application support • Tool presetting • Pricing and availability • Order status • Equipment maintenance • And more Users can save a transcript of their chat for future reference. The chat feature appears on the lower right of any page on BIGKAISER.com. Hoffman Estates, IL – BIG KAISER Precision Tooling announces the promotion of Jack Burley to President/Chief Operating Officer as of January 1, 2021. Chris Kaiser, BIG KAISER President and CEO of 30 years, will take on the role of Executive Advisor.  Jack Burley announced as President & Chief Operating Officer of Big Kaiser Jack Burley announced as President & Chief Operating Officer of Big Kaiser “Jack has been my right hand in this company from the very beginning,” said Kaiser. “He’s shown his leadership in managing the sales and engineering teams and has made many significant contributions to BIG KAISER including new product designs and development. He’s more than ready and deserving of this promotion.” Burley began his career with BIG KAISER more than 30 years ago and is currently Vice President, Sales and Engineering. Burley is a U.S. Marine veteran and earned his degree in mechanical engineering from State University of New York at Alfred. As President/COO of the North American operations for BIG KAISER, Burley will continue to hold his seat on the board of directors for BIG KAISER. “I am very honored and excited about my new position with BIG KAISER, and truly grateful to the executive management at BIG Daishowa and to Chris for placing their trust and confidence in me to lead the company,” said Burley. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed