|

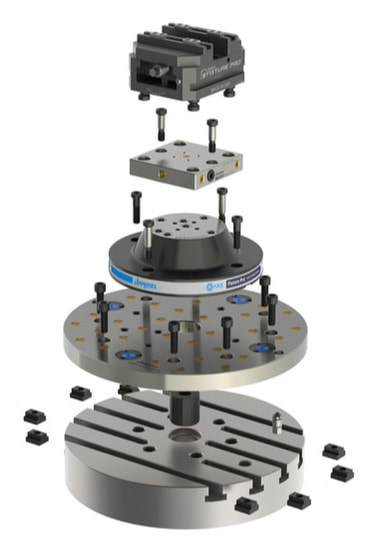

The cast iron tooling columns are said to increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs. EDITED BY CHRIS PASION, Managing Editor, Modern Machine Shop Jergens Inc.introduces its newest cast iron tooling columns that are said to offer maximum rigidity. These columns comprise one single piece of cast iron that is made in the U.S.A. They increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs. Several mounting options are possible, including direct, with center pin locating or edge locating, and also quick-change applications via zero-point system (ZPS) with K20 pull studs and a four module subplate. New column styles include square, cross and rectangular.

Column construction uses stress relieved, class 40 cast iron, with the base and sides milled flat, perpendicular and parallel within 0.001" per ft., providing an accurate foundation on which to setup workholding devices or quick-change systems. Other features include a center locating bore, inch and metric hole patterns, M12 lifting holes for secure hoist ring attachment.

With technical staff support, Jergens tooling columns are customizable as well as easily integrated into full custom design and build projects. Popular patterns and methods include tapped grid, bushed and tapped grid for modular fixturing applications. For quick changes, add either Ball Lock receiver bushings or ZPS modules.

0 Comments

Cleveland, OH - Jergens Inc. is pleased to announce the official launch of our new and improved tooling and workholding website! How to Navigate the NEW Jergens Website:Ready to check it out for yourself? Just CLICK HERE!

Here's a look at some of the new products and special offers from our manufacturers! You'll want to check them out in-person at the show, on-line during the show or contact us and we can stop in and get into the details at your shop with one of our guys. BIG DAISHOWA High-Performance Tooling SolutionsBIG DAISHOWA designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, military, aerospace, energy, and micro-technology industries. BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system Be sure and check out the two special offers:

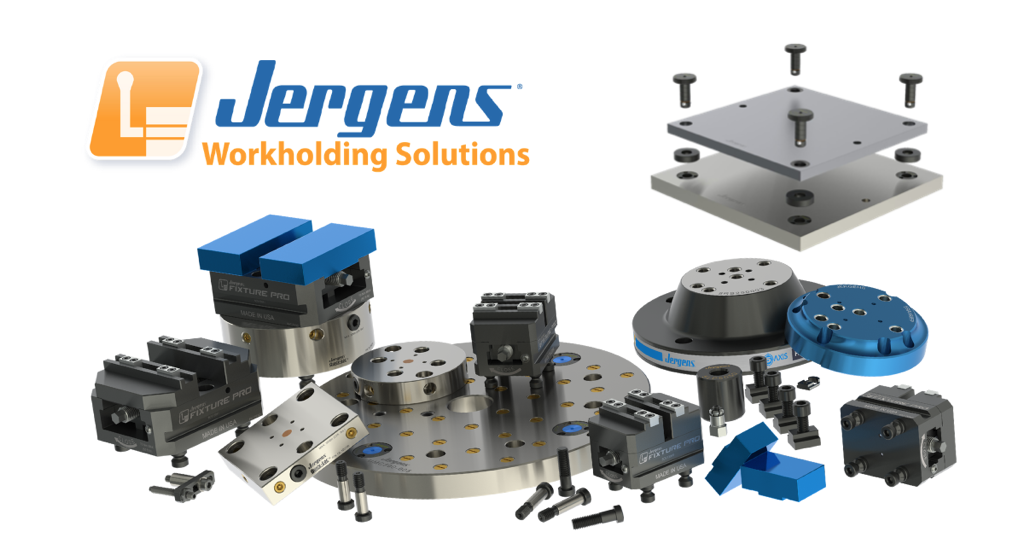

Carmex Precision Tools, LLCCarmex Precision Tools specializes in carbide cutting tools for thread turning & thread milling. They will be showcasing a full line of tools for Swiss machines, including turning, back turning, grooving & parting. Jergens, Inc.Jergens Inc is a global manufacturing leader of CNC machining custom workholding products. Today, you'll find their vises, clamps & fixturing systems, tooling components, at work in just about every segment of the metalcutting industry. Check out their innovative engineered solutions like the patented

Platinum ToolingPlatinum Tooling has been hard at work searching to find the highest quality machine tool accessories in the market…and we think they’ve done it! Platinum Tooling will be showcasing the following products at IMTS:

Techniks Tool GroupTechniks Tool Group (TTG), the parent company of Techniks and Parlec, is one of North America’s largest providers of best-in-class tooling solutions for CNC machining centers. Check out the complete list of products they will be demonstrating at IMTS:

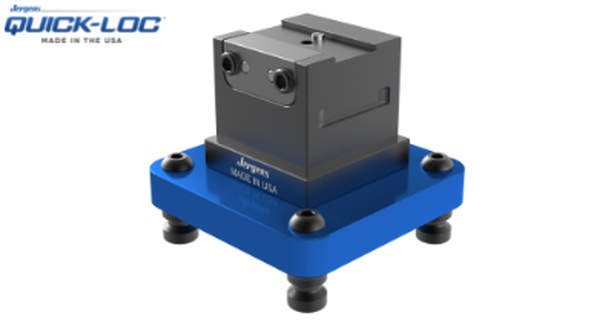

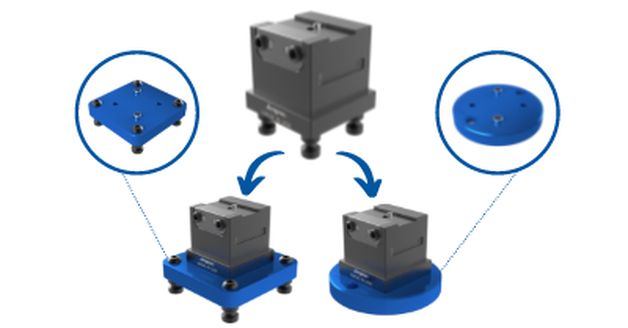

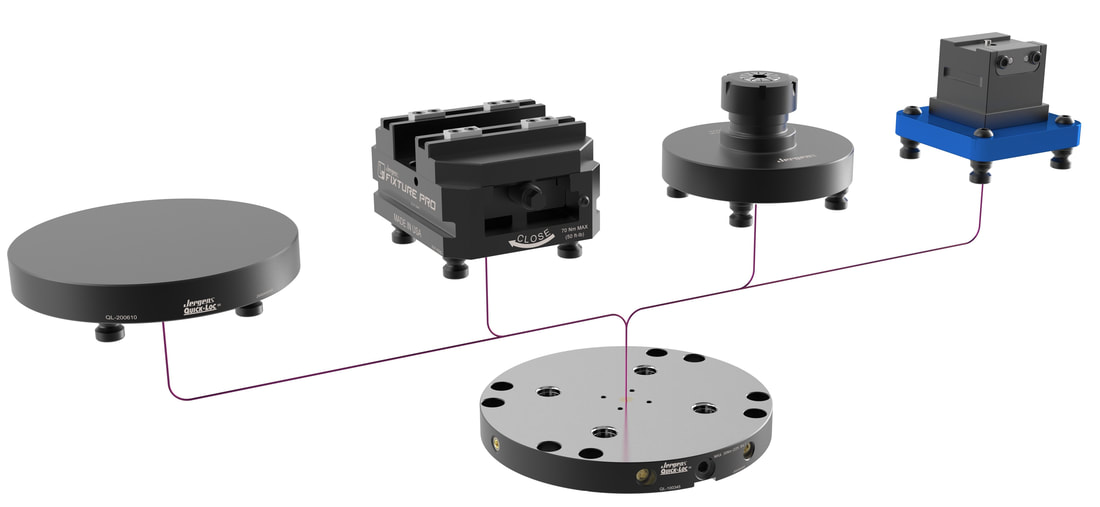

Why dovetail workholding? Dovetail workholding is unique and ideal for holding workpieces that require larger metal removal, and multiple machining passes and operations. The puzzle-piece connectivity provides maximum holding strength with minimum material contact. That means that more of the part is accessible, which is even more advantageous when addressing complex components within limited machining envelopes. All that’s required are a few simple passes with minimal metal removal and your workpiece is ready to grip for a multitude of operations. (Machining) Five Sides on Five-Axis Machining One of the key benefits of dovetail workholding is the unique underneath grip that provides the greatest access to workpieces, making it possible for true five sides machining. Furthermore, dovetails are a versatile solution that can hold a greater variety of parts, in effect reducing the need for custom fixtures and allowing you to standardize on a clamping method and equipment across a wide variety of workpiece types and sizes. Why Jergens? With Jergens Fixture Pro®, you can take the next step in productivity by adding quick-change to the equation. A new group of modular dovetail vises and adapter bases ensures secure clamping and provides Jergens repeatable quick-change solution so you can spend more time in the cut and less time in part changeover. The combination of this type of high-strength workholding with these new modular vises represents a dramatic decrease in overall setup and cycle times. Here's how the math adds up. Part Security + Increased Accessibility + Quick-Change + Number of Parts = Next Level Productivity. Level one: For every securely fixtured workpiece, more operations can be performed without the need to index or reorientate because so much of the workpiece is unencumbered. Level two: When the workpiece needs to be repositioned or changed to the next one, it is done via one of two high-speed changeover solutions - Quick-Loc™ or QLS. Level three: In the case of QLS, several workpieces are loaded along multi-sided columns taking advantage of available vertical (or horizontal) space, filling the machining envelope with numerous parts, and all of those are quick-change as well. Workpieces stay securely clamped in the dovetail vise and adapter base during the changeover to facilitate immediate reloading and secondary operations as needed. Of the new vises, two are engineered with Jergens Quick-Loc™ pallet system and include industry-standard patterns 52mm and 96mm. With a single drive screw, Quick-Loc™ provides fast and repeatable fixture changes for small tooling platforms. A square aluminum adapter base provides the connection to either of the two patterns. A third vise features Jergens Quick Locating System (QLS) mount, for column-mounting possibilities, and a corresponding round adapter base.

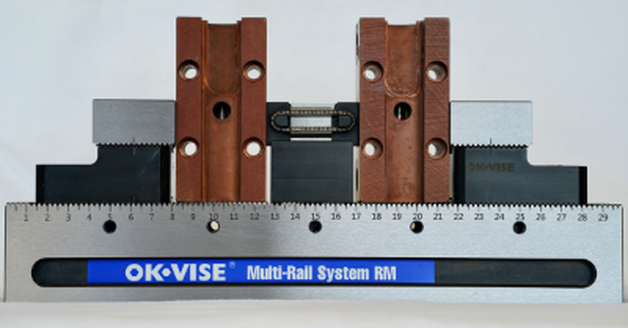

Easier Positioning And Clamping For Multiple Part Setups

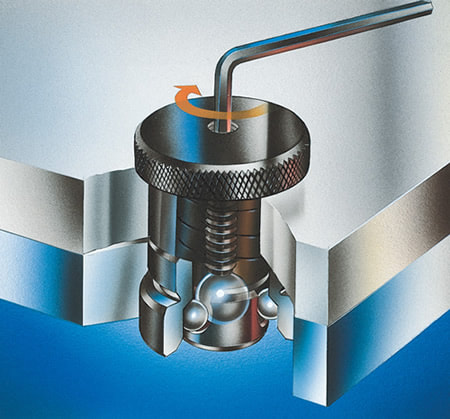

Many machining operations benefit from multiple part setups, right? Maximize machine uptime, capacity and capability. Size, shape and complexity of surfaces to be machined usually dictate what’s possible. So does the total machining envelope that the CNC will allow. Jergens has an answer to how to best position and clamp the highest number of parts while staying clear of tool paths and spindle movements – sound OK? Watch Your Machining Take Off On A Rail The OK-Vise® is Jergens low profile modular clamping system that uses the RM Multi-Rail and clamping modules to hold tight and stay out of the way. General-purpose and totally customizable, Multi-Rail and the other OK-Vise® system components, make it possible, even easy, to configure your workholding exactly to your need in order to optimize machining. We’ve recently added a number of fixture set components for even greater ease of use and capability, including Parallels and Side Guides for positioning, as well as Clamp and Stop Modules to hold workpieces securely during machining. Getting Positioned For Productivity QuicklyT Slot, magnetic and Snap-in Parallels assist in the positioning of a workpiece on the RM rail, avoiding contact with the serrations through a raised datum surface. Mechanical and magnetic Side Guides also assist in positioning the workpiece. They are mounted either to the tapped holes in the side of the rail or via the strong magnet for a wide range adjustment and the ability to move rapidly from one location to another. You can adjust each side guide for a specific product while keeping the guide ready for the next production batch. Clamped In And Held Tight Holding workpieces securely with OK-Vise® is done with Clamp and Stop Modules. In addition to our full line, we have added new B and D Series Clamp Modules that feature a standard clamp combined with a riser plate (B Series), socket head cap screw, and t-nut, as well as a choice of jaw faces – smooth, serrated, mixed and mounting jaw. Stop Modules hold fast against clamping pressure and are also available in several styles including smooth, serrated, knife, V-stops – both vertical and horizontal – and more. In total, this system provides near-endless fixture configurations, consistent holding and machining of challenging workpieces both large and small including multiples clamped simultaneously, and the ability to mount to the Jergens Quick Locating (QLS) Grid System for next-level productivity. For more information on the new OK-Vise® additions, or any of our complete line of workholding solutions, don't hesitate to contact us. FOR IMMEDIATE RELEASE SACRAMENTO, CA. - Next Generation Tooling is excited to announce that effective November 1, 2020, we will be the exclusive agent for California and Nevada for Jergens, Inc. "We've been working with machine shops for a couple decades now to develop more efficient workholding and fixturing methods and we found ourselves in a position of not having a complete product line of workholding solutions that included manual and hydraulic clamping combined with 5 Axis solutions. Jergens checks off all of those boxes" said Chris Savolainen, President of Next Generation Tooling. Jergens Inc's Long History of Workholding on the West Coast.In 1942, Jack Schron, Sr. founded Glenn Tool and Manufacturing, with his father Christy in Cleveland, Ohio. In response to the needs of wartime production, they began to manufacture standard components in the building next door, with the goal of helping American Manufacturers operate quickly and more efficiently. In 1955 Jergens made their first foray in workholding when the received a patent on the Sine Fixture Key and it become the first of many patented workholding items in Jergens' product line. Jergens has a long history on the West Coast as well. In 1981 Jergens, Inc. acquires California distributor Liberty Industrial Company and developed the first 5 axis vises in the early 2000's in their west coast facility well before anyone else was even thinking about 5 axis machining. In the 90's Jergens developed the Ball Lock® Quick change system and in 2008 acquired Bock Workholding form Joe Cousins, who was part of the original team who created the Chick Workholding vise. In 2011, Jergens, Inc. introduced the Fixture-Pro® Line, which was the first comprehensive, modular system approach to 5-Axis Workholding available. NGT to Represent the Workholding Group of the Tooling Component Division (TCD)In 1987 Jergens created three divisions within the company: Assembly Systems Group (ASG), Jergens Industrial Supply (JIS) and the Tooling Component Division (TCD). The Tooling Component Division (TCD) I comprised of of three groups: The Workholding Solutions Group, the Specialty Fasteners Group and the Lifting Solutions Group.

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed