|

OSG is pleased to announce the release of their NEW OSG PHOENIX® PDZ Flat Drill Series!

The OSG PHOENIX® PDZ is an indexable drill series designed for stable flat-bottom hole making. It is an ideal solution for a wide variety of materials such as carbon and alloy steel, stainless steel and cast iron. The following list numbers are associated with the new OSG PHOENIX® PDZ Flat Drill series:

0 Comments

The EXOTAP® A-Tap® is an all-purpose tap series designed to simplify tool management and to excel in a wide variety of materials and applications. The EXOTAP® A-Tap® is made from powdered metal HSS and has OSG's patented V coating to achieve excellent wear resistance.

We are very excited to announce that effective October 1, 2017 we will be representing Precision Cutting Tools Inc. in the California and Nevada market areas. Precision Cutting Tools Inc. was founded in 1963 and ever since has specialized in the production of high-quality cutting tools. Today, with over fifty years of experience, PCT is a leading cutting tool manufacturer that distributes its products all across the United States and Mexico. They have based their company’s success on their long-standing commitment to satisfy our customers’ needs, by utilizing the finest raw materials, introducing innovative cutting tools and providing excellent customer service. We look froward to working with them to develop new Carbide, Cobalt & Powdered Metal end mill and drill substrates and geometries that will meet the material cutting needs we find uniquely on the West Coast. We think you are in for a a real treat once we see what we're working on with PCT!!! Farewell & Parting: Next Generation Tooling ends relationship with MA Ford after 22 years.9/29/2017 After 22 years, Next Generation Tooling has ended our relationship as an independent sales agent for MA Ford in the Northern California and Northern Nevada territories. Our last effective day will be September 30, 2017.

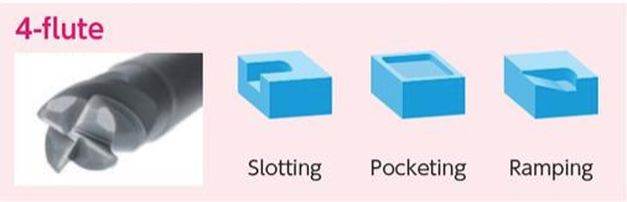

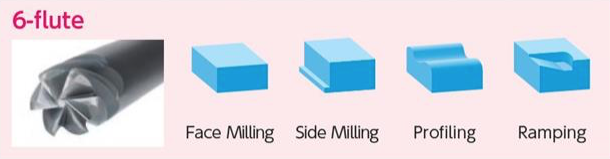

We truly appreciate and greatly value our long, successful relationship fostered by both MA Ford and NextGen since the inception of our company. We realize, with no reservation, that the wonderful people at MA Ford were a huge part of our success by working with us to develop technical solutions and will always value our memories and our personal friendships. At the outset of our relationship in the late 1990's, we worked hand-in-hand with MA Ford to introduce their products to the unique applications and high speed machining that takes place in our markets. In conjunction with the MA Ford engineering team we developed the 138 series end mills for use in aluminum and non-ferrous milling. As a result, many other end mill manufacturer's followed in the footsteps of that tool and began developing material specific tooling. Because of the unique needs of our market, we suggested the expansion of LOC and OAL from what was commonly offered in "Stub, Standard, Long & Extra Long" lengths. The 138 series end mills where the first nationally recognized brand to offer 7 different lengths of cuts as stock standard. We are very grateful to everyone at the MA Ford team who has worked with us hand-in-hand for so many years, and wish only the best for MA Ford in the future. NTK's industry leading line of ceramic cutting tools is expanding with new solid ceramic end mills. It's time to upgrade from carbide to this unique "SX9" SiAlON end mill which increases productivity more than 10 times over traditional end mills when machining Heat Resistant Super Alloy (HRSA) materials. NTK's durable SX9 grade can run at speeds of 2000 SFM. The line-up includes 4 and 6 flutes in inch and metric versions. The NEW SX9 SiALON Ceramic end mills are available in both a 4 flute and 6 flute configuration and can be used for slotting, pocketing, ramping, face milling, side milling and profile milliing. Contact a Next Generation Tooling Regional Manger for more information or for an on-site demonstration. For more infomation abotu machinginig parameters please see:

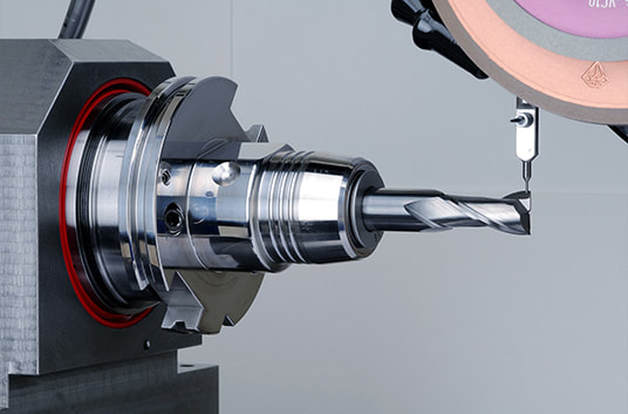

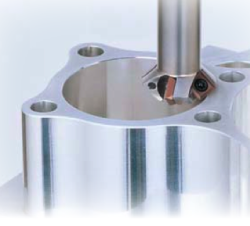

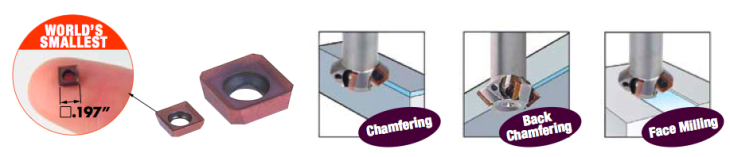

General Guidelines for Successful Milling with NTK Ceramics Everyone wants to chamfer quickly but still keep a fine surface finish. The Big Kaiser C-Cutter Mini was developed to deliver ultra high speeds and feeds. Now you can greatly multiply cutting efficiencies with the new C-Cutter Mini from Big Kaiser. The compact, multifunctional, ultra high feed chamfer mill. Whether you need to chamfer, back chamfer or even perform light face milling, the C-Cutter Mini has you covered.

The C-Cutter Mini is now available with an offset body extension to achieve bolt hole and tap chamfers. The new design utilizes a single insert to achieve 45 degree top and bottom chamfers while the offset design avoids interference with the inside of the hole. Chamfer diameters range from .217" - .827" with tap sizes ranging from M8-M20 and bolt sizes ranging from M6 to M16. Multiple extension lengths are available to reach through holes as deep as 3.031". The newly introduced SE (Sharp Edge) insert type prevents burrs and is recommended for stainless and mild steel applications. Increased reach is now possible with new long-type models for existing single-, 3- and 4-insert designs for front & back chamfering, and even light face milling (4-insert model only). Another expansion to the line includes the world's smallest hexagon insert. The hexagonal design provides additional angles and more indexes for superior cutting speeds on the smallest single- and multi-insert C-Cutter Mini models. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed