|

This article originally appeared in the Gazette Xtra and I thought it had some great information to pass along to everyone to give you some background on Performance Micro Tool JANESVILLE — As a small Janesville manufacturer, Performance Micro Tool likes to fly under the radar.

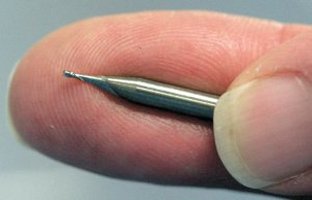

Performance Micro Tool's tools have been used to route communications equipment on the Mars Rover project, cut mother of pearl dots on the frets of Gibson guitars and make a harness for a fruit fly. Its tools cut the "plus" and "minus" signs on the sides of 4 million iPhone 4s. Burton said his company prefers a low profile, primarily to keep competitors off guard. That, however, is becoming more difficult. The Wisconsin Entrepreneurs' Network recently named Performance Micro Tool as one of 33 "Wisconsin Companies to Watch." The annual program recognizes companies that demonstrate high performance in the marketplace and exhibit innovative products, services or processes. Performance Micro Tool got its start after Burton watched a progression of big companies pass along ownership of a Janesville facility. The companies started with International Carbide and ended with Kennametal, a huge company with more than 100 facilities. "We were always owned by some out-of-state manufacturer, and in the public sector, the mantra is always the next quarter," Burton said. Kennametal ultimately closed its Janesville shop and shipped the work to a plant in China. Burton and his partner launched Performance Micro Tool. Kennametal soon found that its China plant couldn't do what Performance Micro Tool did, and Kennametal became one of Burton's largest customers. The 12 employees of Performance Micro Tool work across three shifts in a shop on Kennedy Road on Janesville's north side. Machines that robotically grind the tools fill the shop.

"Making them small is certainly our niche," Burton said. "We also do a lot of private labeling, which helps keep competitors off our backs. "We try to keep our prices pretty low to keep competitors from getting into the business and keep them buying from us." Burton credits the company's steady growth to a stable group of dedicated, talented employees, many of who have been with him for years. "These guys will take a bullet for me and this company," he said. "We have an open shop. We're pretty lax and encourage creativity and playing around." Burton said the company pays high wages, covers 100 percent of its health care plan, provides a 401(k) match and often gives bonuses that have included companywide cruises, trips to Cancun and last year involved a Packer-Viking weekend in Minneapolis. "These guys are really concerned about the health of the company," Burton said. "I give them a bonus, and they ask me if I'm sure. "If I wasn't sure, I wouldn't do it. When times are good, we share." Times have been good. A look at the company's growth chart shows a steadily increasing line offset by routine ups and downs. Burton doesn't want to see his company grow too quickly. He knows that fast ups can create fast downs. "If we were to double in size next year, our customer base would suffer, no doubt," he said. In 2009, Performance Micro Tool's sales were off 15 percent when its competitors experienced declines of 45 percent to 60 percent.

"I might tell a customer it will be three days, but my guy on the floor will look at it and say 'I'm gonna knock this out in one day because there's potential here,'" Burton said.

Performance Micro Tool is the definition of innovation, said Phil Jackson, the Wisconsin Entrepreneurs' Network regional director who nominated the company for the award. "These guys are doing cutting-edge work, no pun intended," Jackson said. "And they're not just sitting here in Janesville looking at U.S. markets. They're looking internationally."

0 Comments

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed