|

NEW YORK--(BUSINESS WIRE) - Techniks Tool Group (“TTG)”, one of the largest manufacturers and suppliers of branded highly engineered, consumable, high-cost-of-failure aftermarket and OEM tooling products in North America, announced that it has acquired Eppinger Group (“Eppinger”), a Denkendorf / Baden-Württemberg, Germany-based leading designer and manufacturer of sophisticated, high precision static and live tools, complete CNC (Computerized Numerical Control) tooling systems, rotary tables for CNC machines, and gears and gearboxes for robotics applications. TTG is a portfolio company of Z Capital Partners, L.L.C., the private equity fund management arm of Z Capital Group, L.L.C. ("ZCG"), a leading privately held merchant bank. The transaction is expected to close later this week. Founded in 1925, Eppinger is one of the leading mechanical engineering companies in the field of development and production of tool holders, specifically for CNC turning & milling centers and precision gears. Eppinger has three manufacturing and distribution facilities located in Germany, India, and the U.S. and holds extensive direct relationships with machine shops, machine OEMs and robot manufacturers in Europe and Asia. The combined business will be named Eppinger Technologies and will expand its broad product offering of highly engineered solutions to cover both milling and lathe CNC machines. Eppinger leadership, including CEO Uwe Eppinger, will remain with the combined business. Mr. Eppinger will also remain an investor in the combined company. "This transaction will enhance our global positioning and provide us with a broader platform, expanded manufacturing and distribution channels, and a wider customer set from which to grow," said Dean Glover, CEO of TTG. "The combined entity will be renamed Eppinger Technologies, and we will continue to build upon our industry-leading channel presence and diversified suite of products." “We are pleased to add Eppinger, a company with a rich German engineering history in providing the highest quality products to its customers, to our portfolio. Eppinger is a highly complementary business to Techniks Tool Group and together, they represent an extremely compelling partner in the attractive tooling market,” said James Zenni, Founder, President and Chief Executive Officer of ZCG. “We look forward to building on this strategic combination to continue to capture market share and drive substantial global growth.” “For nearly 100 years, Eppinger has focused on providing the finest high-quality solutions for our customers,” said Mr. Eppinger. “We were attracted to the ZCG team and Techniks Tool Group because they share our focus on innovation, superior quality, technical support and customer service, and we are excited to partner together to address the technical needs of an expanded customer base across the market spectrum.” About EppingerThe Eppinger Group is a company based in Denkendorf / Baden-Württemberg. The company has been specializing in precision tools for lathes for almost 100 years and is a leader in the design and manufacture of tool holders for CNC Turning & Milling Centres. Eppinger currently has more than 53 patents underpinning a product range that includes fixed and driven tool holders and complete tool systems. Recent Eppinger Innovations include rotary tables and industry leading precision gear units that are used in all areas of mechanical engineering. The product range includes angular and coaxial gear units as well as geared motors for a wide variety of applications in automation, robotics and mechanical engineering. The high-quality products occupy a leading position on the international market. Eppinger offers individual and end-to-end solutions from a single source: from development and design to production. For more information, please visit https://eppinger.de/en/. About Techniks Tool GroupTechniks Tool Group is the North American industry leader in high quality branded toolholding and workholding solutions for demanding and high precision CNC applications. TTG has an unparalleled network spanning the manufacturing and tooling industries with a focus on strategic supplier relationships, leading channel access, extensive engineering capabilities and unmatched customer support. For more information, please visit www.technikstoolgroup.com. About ZCG ZCG is a leading, privately held merchant bank comprised of private markets asset management, business consulting services, technology development and solutions.

For almost 30 years, ZCG Principals have invested tens of billions in capital and have industry leading track records in private equity and credit. ZCG has approximately $6.5B of AUM in asset management and its investors are some of the largest and most sophisticated global institutional investors including pension funds, endowments, foundations, sovereign wealth funds, central banks, and insurance companies. ZCG has a global team comprised of over 375 professionals. For more information, please visit www.zcg.com.

0 Comments

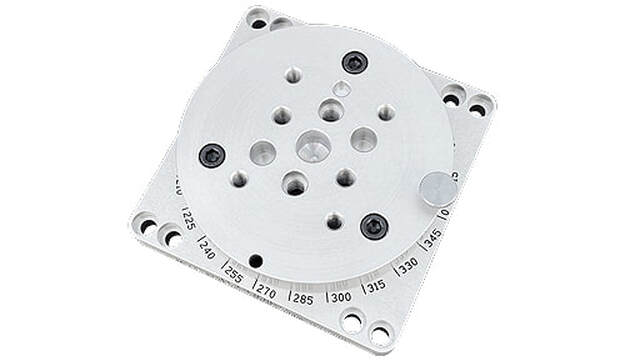

+1Axis Indexer allows you to easily and economically add another axis to your machining. The +1Axis Indexer is adjustable in 15° increments and is compatible with the Techniks DV-075 Dovetail Vise, the 5th Axis D-22 Dovetail Fixture and the Raptor RWP-024 and RWP-024SS Dovetail Fixtures. You can now perform accurate 3+1 index machining on 3-axis machines for one workpiece or multiple positions across a fixture plate. On a 4-axis machine you can perform 4+1 axis machining in a single part setup or, if mounting multiple +1Axis Indexers on a rotary tooling block, you can perform 4+1 machining on several parts gaining access to 5 sides of the workpiece. Using the +1Axis indexer on a 5-axis machine allows access to workpiece faces that are unreachable on common pyramid riser block setups.

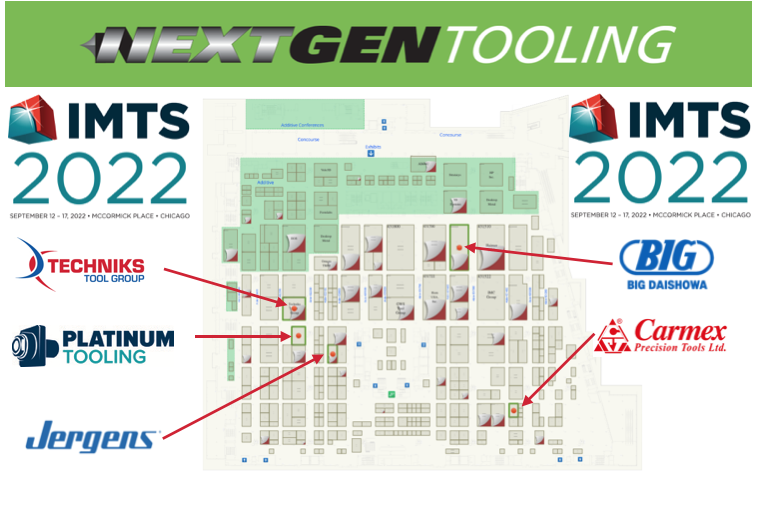

Here's a look at some of the new products and special offers from our manufacturers! You'll want to check them out in-person at the show, on-line during the show or contact us and we can stop in and get into the details at your shop with one of our guys. BIG DAISHOWA High-Performance Tooling SolutionsBIG DAISHOWA designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, military, aerospace, energy, and micro-technology industries. BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system Be sure and check out the two special offers:

Carmex Precision Tools, LLCCarmex Precision Tools specializes in carbide cutting tools for thread turning & thread milling. They will be showcasing a full line of tools for Swiss machines, including turning, back turning, grooving & parting. Jergens, Inc.Jergens Inc is a global manufacturing leader of CNC machining custom workholding products. Today, you'll find their vises, clamps & fixturing systems, tooling components, at work in just about every segment of the metalcutting industry. Check out their innovative engineered solutions like the patented

Platinum ToolingPlatinum Tooling has been hard at work searching to find the highest quality machine tool accessories in the market…and we think they’ve done it! Platinum Tooling will be showcasing the following products at IMTS:

Techniks Tool GroupTechniks Tool Group (TTG), the parent company of Techniks and Parlec, is one of North America’s largest providers of best-in-class tooling solutions for CNC machining centers. Check out the complete list of products they will be demonstrating at IMTS:

Download CAD Drawings for you toolholders! Techniks is excited to announce that they are entering into a new stage of development for their website. Over the past several weeks Techniks has compiled 2D and 3D model files for each product available on www.techniksusa.com. That’s almost 4,800 total SKUs, 9,600 2D and 3D model drawings added for your convenience! The addition of downloadable CAD files is just the next phase in thier continued development of their site to improve its user-friendliness. You can now find your specific drawings through directly searching for the part number in the “Drawings” section of the main menu or by navigating directly to the product page. Simply navigate to the appropriate product table, locate the item you need, and click on the drawing file format you require. You will see a links to the 2D DWG and 3D STP files in the right-hand columns. Can’t find what you’re looking for?

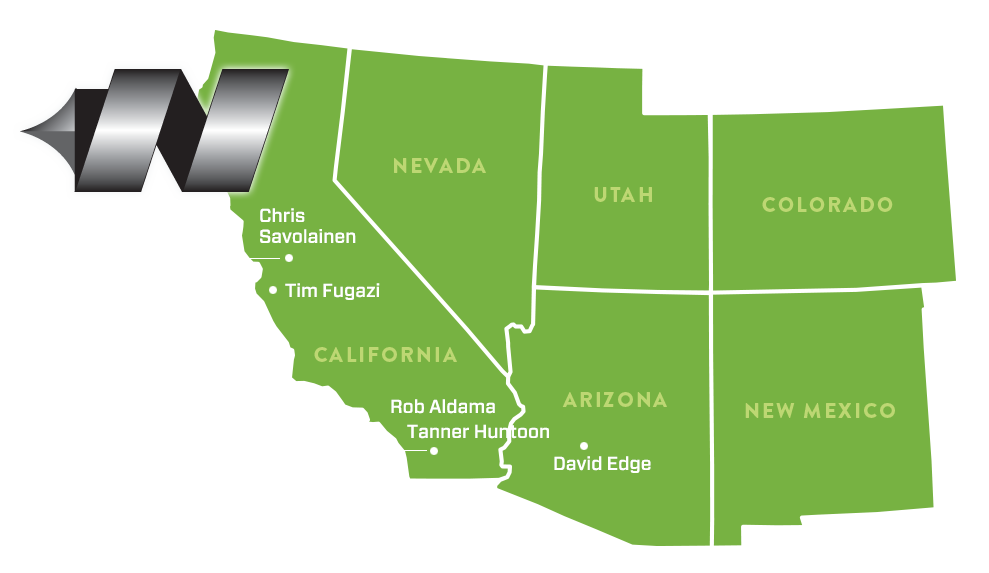

Techniks is adding more drawings every day, but if you do not find the drawings you need let them know at [email protected] and they'll prioritize your request to get you the drawings you need, FAST! As you begin to take advantage of their available CAD files, please don't hesitate to continue to provide feedback on your website experience to us and we can pass it along to Techniks. It’s been with your help that Techniks is able to provide the highest levels of customer service. A lot of that feedback comes form us passing along that information from you! Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

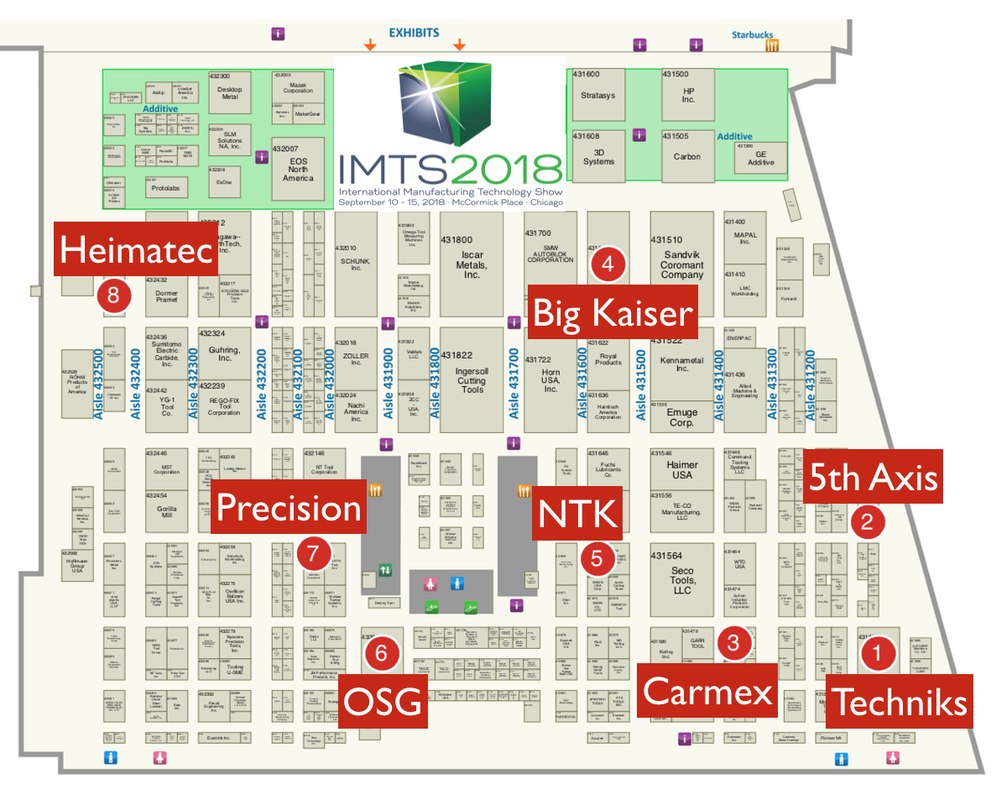

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations. Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075 |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed