|

Hoffman Estates, IL – BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, introduced Hydraulic Chucks for Swiss lathes in 2018, the first improvement to the technology in more than 30 years. This year, the program has expanded to include inch-size Standard Type chucks, as well as new F Type and R Type chucks.

Standard Type Hydraulic Chucks with tool-side clamping are now available in inch sizes with the clamping range of ø1/8”, 3/16” and 1/4”. The new F Type’s single wrench enables easy cutting tool changes on the tool post. The easy-access rear clamping design is ideal for front tool post. Clamping from the opposite side of the cutting tool and optimum-length design improves overall ease of use. The F Type is available in a clamping range of ø3-10mm and coolant delivery is possible with an Rc(PT)1/8’’ screw. The new R Type eliminates interference at both the upper or lower tool post positions with a unique block design and tightening at an offset position in the tool side. The R Type is available in a clamping range of ø3-10mm and its oil hole drills can be used for coolant delivery when mounted on the upper section. To minimize machine downtime and provide operator safety, these Hydraulic Chucks use a simple hex wrench that requires only two to three turns for both clamping and unclamping. Tightening is complete when the clamping screw hits the bottom; controlling tightening torque is not needed. Once a Hydraulic Chuck is centered, the runout will not vary, even if a cutting tool is changed repeatedly. Runout of fewer than three microns at four times diameter can be achieved. Hydraulic Chucks have a standard pipe thread for coolant-through connection and are available for most Citizen and Star machines with 3/4'’ or 22mm straight shank.

0 Comments

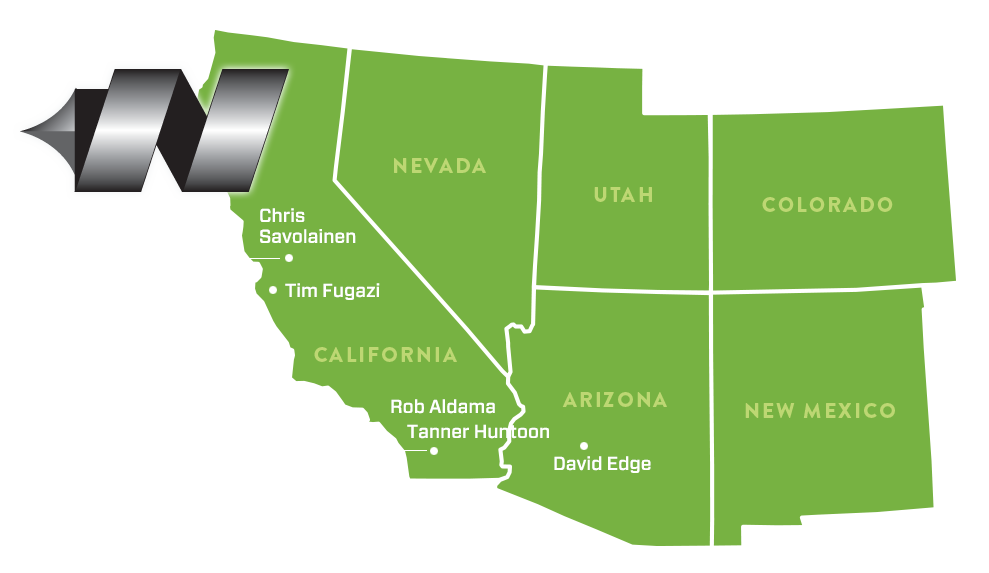

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Breaking NEWS from Platinum Tooling: ER Collet Chucks are available in single or double ended style and come in various lengths. Offered in both metric or inch sizes, these tools can be ordered in round or with flats. Tecnicrafts manufactures these toolholders to a tight run out tolerance of 5 microns or less and adheres to the h6 standard for shank diameter. All Tecnicrafts Collets and Guide Bushings are available in Standard and Ultra-Precision grades. The bore profiles include Round, Square, Hexagon, Rectangle and Custom as per customer specifications. The collets are offered in steel and carbide lined versions with Grooved, Smooth, or Serrated bores in Standard and Long Nose types. Special V-line and Over-Grip collets are also available. Tecnicrafts Guide Bushings are generally offered in carbide lining with U-line, Over-Grip, and Extended Nose & Long Bores available.

Tecnicrafts Swiss Collets & Guide Bushings are also available to complement your machining operations. For quick delivery, Platinum Tooling inventories the most common sizes and styles of Collets & Guide Bushings at their headquarters located in Prospect Heights, Illinois. Non-standard items are available to ship within 3-4 weeks.

Platinum Tooling is stocking many common styles and sizes of Tecnicraft collets and guide bushings at their Illinois facility.

These high quality collets and guide bushings for Swiss type CNC lathes are manufactured with run-out tolerances as low as 5 microns. Also available for special order with long nose, extended carbide, and special bore shapes. Hoffman Estates, IL – BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announces the MEGA Micro Coolant Nut, a solution developed to provide precise coolant supply to micro cutting tool applications at high speeds. Efficient coolant delivery prevents chip jamming, which can cause machine stoppages, service calls, and increase tool wear and poor surface finish. As spindle speeds continue to increase, getting the coolant to the cutting tip has become more challenging.

Exclusively for MEGA Micro Chuck 6S, the MEGA Micro Coolant Nut is an ideal design for high-speed micro machining up to Ø6 mm. By using it instead of a standard nut, tool lifetime is increased by about 35 percent and better cutting performance is achieved for milling applications. The MEGA Micro Coolant Nut is a continuation of BIG KAISER's efforts to drive coolant toward the cutting edge and help to maintain process security. For coolant through drills, BIG KAISER offers the MEGA Micro Perfect Seal Nut. If coolant is required, it should be optimized to maximize its true potential. For more information please contact us! Heimatec Inc., the North American importer of Live Tooling and Angle Heads, is now Platinum Tooling Technologies, Inc. As Platinum Tooling, they are committed to providing the same superior quality products and service but with an expanded product offering.

In addition to their continued commitment to Heimatec tooling for all major Live Tool lathes, Next Generation Tooling and Platinum Tooling are excited to bring you complementary machine tool accessories from Tecnicrafts, Henninger, AMF, and Suzuki. For Swiss machines, we will continue to offer Heimatec Live Tools, but now will also provide tooling solutions from Tecnicrafts Precision Collets and Guide Bushings and Suzuki Live Tool speed increasers. For Machining Centers, we offer Heimatec standard Angle Heads, Henninger Spindle Speed Increasers and custom Angle Heads. In addition, we offer AMF markers, cleaners, and radio sensor systems to help maximize existing equipment for long term cost savings. Platinum Tooling's recent office and warehouse expansion have allowed them to increase inventory and staff to better serve their customer’s needs. 2018 is looking good!! Techniks new catalog is at the press and is available on the Techniks website for digital download.

You can click the link above or the picture below to get your copy or give a call and we'll drop on off to your shop! |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed