|

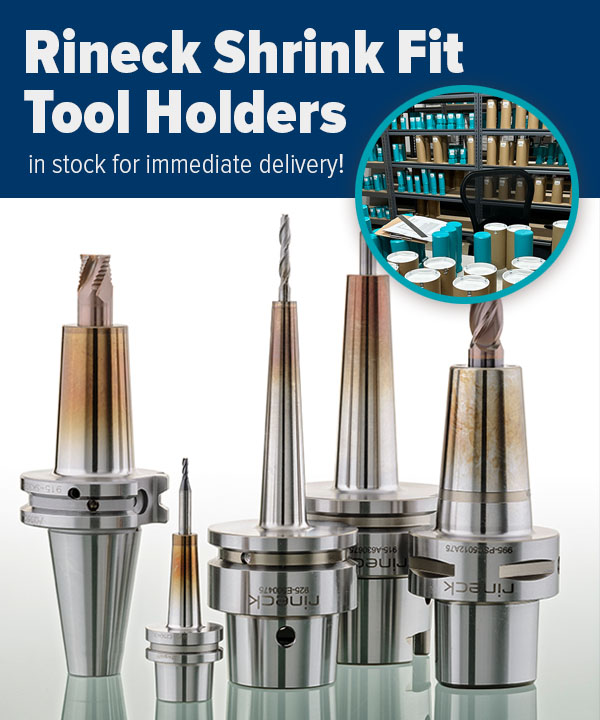

Platinum Tooling now inventories a wide selection of Rineck Shrink Fit Tool Holders in the most common styles and sizes at thier headquarters in Prospect Heights, Illinois. These high-quality German made tool holders are produced for high accuracy and maximum rigidity.

Stock tools are available in imperial (inch) and metric sizes with slim 3° and standard 4.5° execution with the following machine connections:

For more information on Rineck Shrink Fit Tool Holders or any of our other precision machine tool accessory lines, contact us!

0 Comments

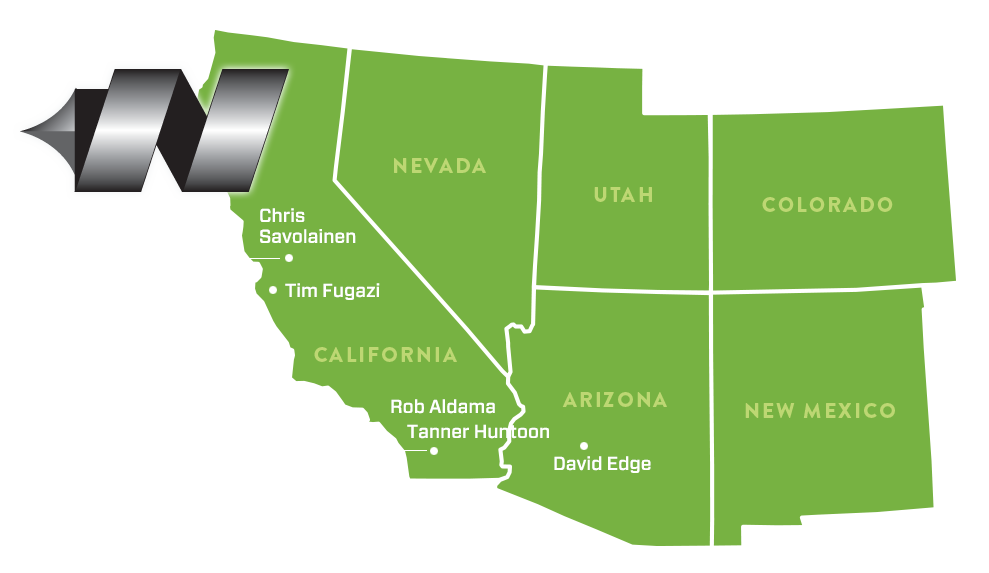

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Farewell & Parting: Next Generation Tooling ends relationship with MA Ford after 22 years.9/29/2017 After 22 years, Next Generation Tooling has ended our relationship as an independent sales agent for MA Ford in the Northern California and Northern Nevada territories. Our last effective day will be September 30, 2017.

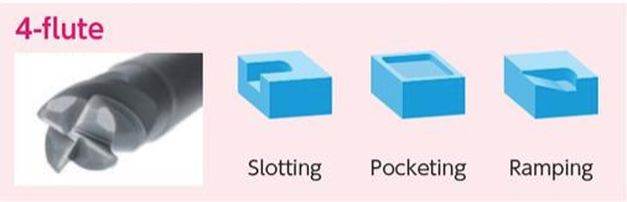

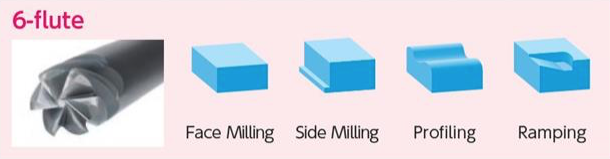

We truly appreciate and greatly value our long, successful relationship fostered by both MA Ford and NextGen since the inception of our company. We realize, with no reservation, that the wonderful people at MA Ford were a huge part of our success by working with us to develop technical solutions and will always value our memories and our personal friendships. At the outset of our relationship in the late 1990's, we worked hand-in-hand with MA Ford to introduce their products to the unique applications and high speed machining that takes place in our markets. In conjunction with the MA Ford engineering team we developed the 138 series end mills for use in aluminum and non-ferrous milling. As a result, many other end mill manufacturer's followed in the footsteps of that tool and began developing material specific tooling. Because of the unique needs of our market, we suggested the expansion of LOC and OAL from what was commonly offered in "Stub, Standard, Long & Extra Long" lengths. The 138 series end mills where the first nationally recognized brand to offer 7 different lengths of cuts as stock standard. We are very grateful to everyone at the MA Ford team who has worked with us hand-in-hand for so many years, and wish only the best for MA Ford in the future. NTK's industry leading line of ceramic cutting tools is expanding with new solid ceramic end mills. It's time to upgrade from carbide to this unique "SX9" SiAlON end mill which increases productivity more than 10 times over traditional end mills when machining Heat Resistant Super Alloy (HRSA) materials. NTK's durable SX9 grade can run at speeds of 2000 SFM. The line-up includes 4 and 6 flutes in inch and metric versions. The NEW SX9 SiALON Ceramic end mills are available in both a 4 flute and 6 flute configuration and can be used for slotting, pocketing, ramping, face milling, side milling and profile milliing. Contact a Next Generation Tooling Regional Manger for more information or for an on-site demonstration. For more infomation abotu machinginig parameters please see:

General Guidelines for Successful Milling with NTK Ceramics |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed