|

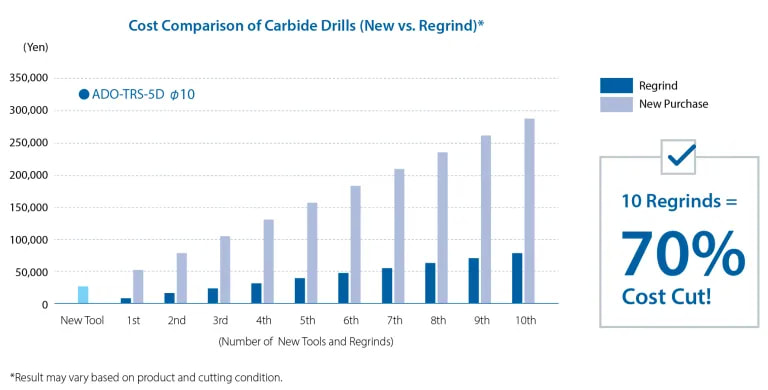

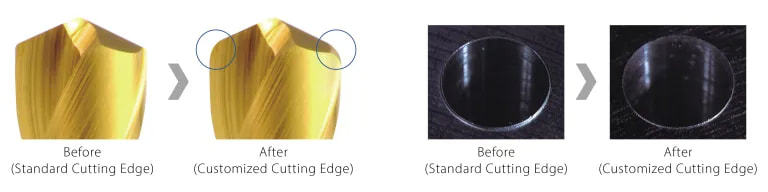

Enhancing sustainability by tool reconditioning and recycling services by Masatoshi Kageyama | OSG Corporation As a global company manufacturing responsible products, OSG is committed to a healthy planet and society. In order to reduce environmental impact, OSG actively implements initiatives relating to resource and energy conservation, waste reduction, prevention of pollution, and material recycling in various processes throughout the OSG Group. OSG’s tool reconditioning program is a part of the company’s commitment to promote resource conservation and to improve energy efficiency in its business activities. The primary benefit of tool reconditioning is obvious: reduction in overall tooling costs. Although many shops regrind their own drills, few shops have given thought to regrinding high performance cutting tools, even though substantial cost savings can be obtained. These efforts not only save customers thousands of dollars each year but are also environmentally friendly and sustainable. As a comprehensive cutting tool manufacturer, OSG is capable of regrinding and recoating an array of products, such as solid carbide tools, HSS tools, PCD tools, rolling dies, specials, and more. Tool reconditioning services provided by OSG restore used tools to like-new condition. OSG’s tool reconditioning division uses original OSG manufacturing drawings for all regrinding processes. OSG Group companies also adhere to the OSG quality control manual and use the same inspection equipment used by the manufacturing division during the inspection procedures. With tool reconditioning facilities in 14 countries, OSG can respond to customer needs worldwide. In addition to tool reconditioning, OSG also offers customization services to help manufacturers optimize machining based on individual application needs. OSG USA's Regrind CapabilitiesOSG USA has comprehensive Regrind and Coating Capabilities for Drills, End Mills, Reamers, Taps and more! Get the best coating based on your application and tool. Additional Coatings available. Drills

End Mills

Reamers

How to Get the Ball RollingEvaluation Services Tailored for Your Needs

To begin, contact your nearest Next Generation Tool regional manager to set up an evaluation appointment. We will evaluate each and every one of your application before sending the tools off for reconditioning.

0 Comments

OSG Tap & Die is pleased to announce the following release of NEW product and product expansions to the OSG line-up.

This is one of the largest number of new products released all at one time! A separate product release for each product is available with further details including features and benefits of each new product/expansion. Simply click on the link for each product to be directed to the individual product release announcement. The following is a complete list of NEW products and their associated list numbers: DRILLS: NEW Drill Series: A Brand® ADO-TRS Advanced Performance High Feed 3-flute Drill Series

A Brand® ADFLS-2D Flat Bottom Drill Series

A Brand® ADFO-3D Flat Bottom Coolant-Through Drill Series

A Brand® ADO-SUS 8D Extended Reach Drill Series

A Brand® AD-LDS Advanced Performance Spot Drills

EXPANSION to DRILL SERIES: A Brand® ADO-SUS 3D & 5D Series

TAPS NEW TAP SERIES: A Brand® AT-1 Thread Mill Series

A Brand® A-CSF Spiral Flute Carbide Tap Series

A Brand® A-CHT Straight Flute Carbide Tap Series

END MILLSNEW END MILL SERIES: A Brand® AE-VMS End Mill Series

Expansion to End Mill Series EXOCARB® AERO DLC Series

EXOCARB® UVX-Ti Series

INDEXABLES Expansion to Indexable Series OSG Phoenix® PXM Exchangeable Head End Mill Series

OSG Phoenix® PXD Exchangeable Head Drill Series

OSG Phoenix® PSTW 90° Shoulder Cutter Series

OSG Phoenix® PSFL 90° Roughing Cutter Series

OSG Phoenix® PD Indexable Drill Series

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed