|

Easier Positioning And Clamping For Multiple Part Setups

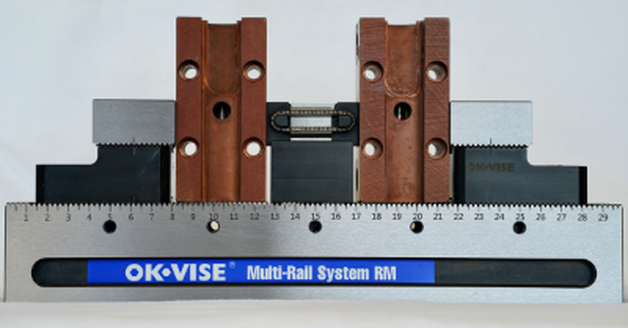

Many machining operations benefit from multiple part setups, right? Maximize machine uptime, capacity and capability. Size, shape and complexity of surfaces to be machined usually dictate what’s possible. So does the total machining envelope that the CNC will allow. Jergens has an answer to how to best position and clamp the highest number of parts while staying clear of tool paths and spindle movements – sound OK? Watch Your Machining Take Off On A Rail The OK-Vise® is Jergens low profile modular clamping system that uses the RM Multi-Rail and clamping modules to hold tight and stay out of the way. General-purpose and totally customizable, Multi-Rail and the other OK-Vise® system components, make it possible, even easy, to configure your workholding exactly to your need in order to optimize machining. We’ve recently added a number of fixture set components for even greater ease of use and capability, including Parallels and Side Guides for positioning, as well as Clamp and Stop Modules to hold workpieces securely during machining. Getting Positioned For Productivity QuicklyT Slot, magnetic and Snap-in Parallels assist in the positioning of a workpiece on the RM rail, avoiding contact with the serrations through a raised datum surface. Mechanical and magnetic Side Guides also assist in positioning the workpiece. They are mounted either to the tapped holes in the side of the rail or via the strong magnet for a wide range adjustment and the ability to move rapidly from one location to another. You can adjust each side guide for a specific product while keeping the guide ready for the next production batch. Clamped In And Held Tight Holding workpieces securely with OK-Vise® is done with Clamp and Stop Modules. In addition to our full line, we have added new B and D Series Clamp Modules that feature a standard clamp combined with a riser plate (B Series), socket head cap screw, and t-nut, as well as a choice of jaw faces – smooth, serrated, mixed and mounting jaw. Stop Modules hold fast against clamping pressure and are also available in several styles including smooth, serrated, knife, V-stops – both vertical and horizontal – and more. In total, this system provides near-endless fixture configurations, consistent holding and machining of challenging workpieces both large and small including multiples clamped simultaneously, and the ability to mount to the Jergens Quick Locating (QLS) Grid System for next-level productivity. For more information on the new OK-Vise® additions, or any of our complete line of workholding solutions, don't hesitate to contact us.

0 Comments

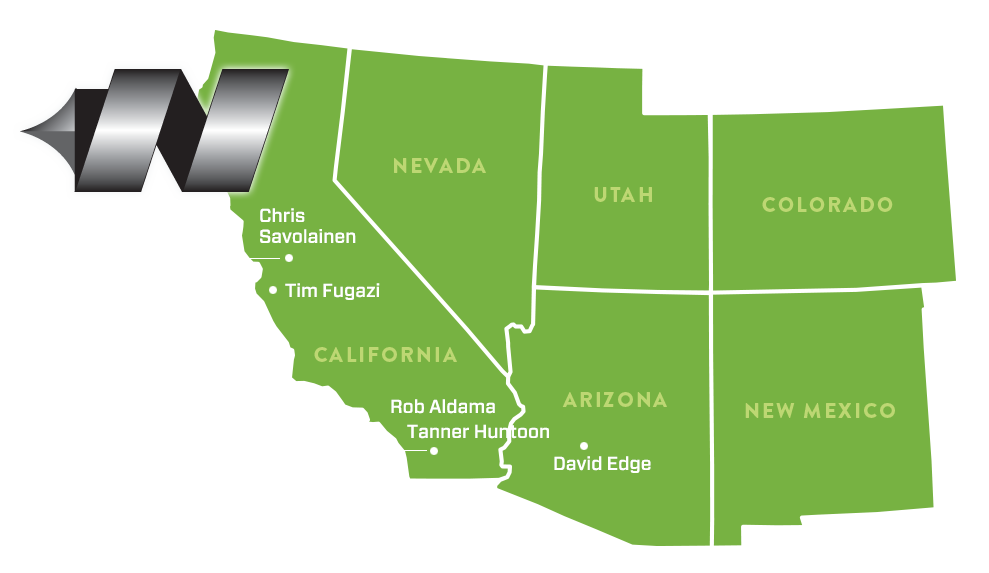

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

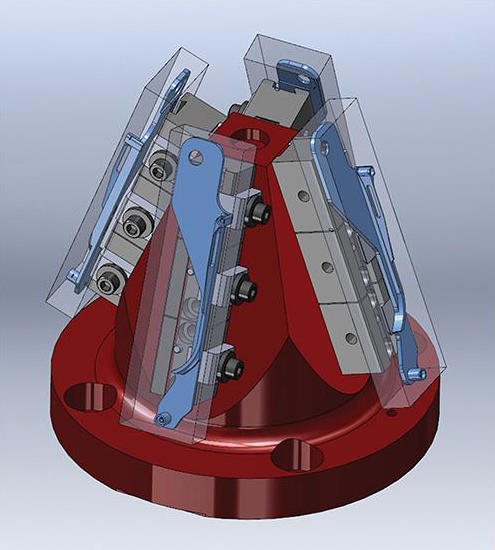

In case you missed How Its Made, Season 24, episode 9, featured a show on 5TH Axis Metalworking Vises! Check it out over lunch!  David Edge David Edge We are very excited to announce that David Edge has joined the Next Generation Tooling team. David has a wealth of experience from his 45+ years in the metalcutting industry. He not only knows the technical aspects of cutting tool applications but also the procedural functions that are important to manufacturers, Industrial distributors and machinery dealers. David began his career in 1972 as a manufacturing engineer in turning applications, with Pneumatic Auto Turret lathes, Tracer lathes and manual Turret lathes. He cut his teeth in sales for 11 years as a cutting tool specialist for Valenite in the Bay area. He moved north to work for RTW and Iscar where he managed Washington, Oregon and Western Canada for the many aerospace applciations in that area. In 2012 he moved back to the Bay area to manage Northern California for Tungaloy. David also brings first hand experience as a distributor from his time at J&L Industrial Supply and Aronson-Campbell Industrial Supply as a carbide application engineer. He has a deep understanding of what the expectations are of a industrial distributor from a manufacturer. David also has an inside knowledge of the expectations of a machine tool dealer from his time back in the late 1980's working at Selway Machine Tools.

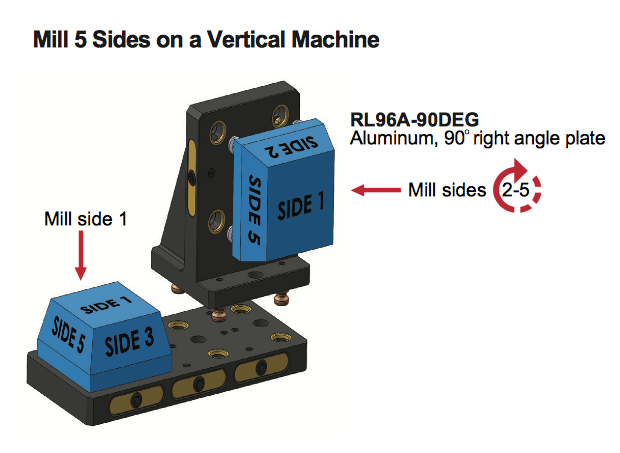

The RockLock quick change system is here. Featuring Industry standard 96 mm pull stud spacing. Standardize them all with incredible speed and repeatability.

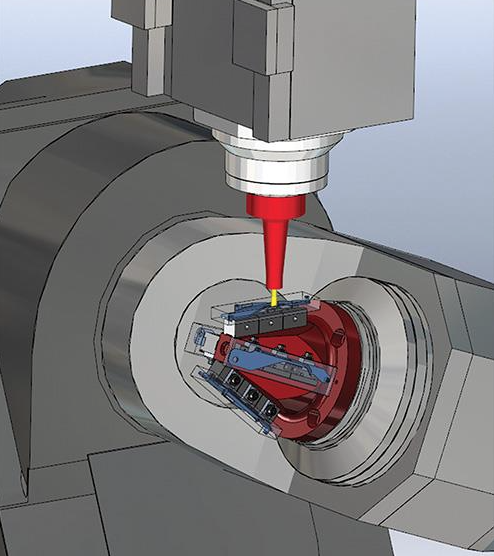

Note: This article originally appeared as a Case Study From: 5/1/2016 Modern Machine Shop, Edited by Emily Probst , Associate Editor VIDEO NOTE: Scroll to the bottom of the page for a behind-the-scenes look at 5th Axis, and hear Chris Taylor talk about how Hypermill software has helped his company. From day one, 5th Axis Inc.’s business strategy has been to take advantage of the most advanced software, equipment and technologies available so it could competitively enter demanding niche markets like aerospace, medical and other challenging high-tech industries. However, during the company’s entry into five-axis machining, co-founders Steve Grangetto and Chris Taylor realized their CAM software had major shortcomings—machining collisions were common, and they weren’t able to realize the full potential of their machine tools. Using Hypermill from Open Mind Technologies AG of Wessling, Germany, the company achieves faster run times, better surface finishes and overall better quality

Business grew dramatically during the company’s first three years. To meet the growing demand for complex, five-axis machining, 5th Axis purchased a new high-performance five-axis machine to accompany its original Haas machine. However, during programming, the company realized the shortcomings of its existing, mainstream CAM software. Along with unexpected machining collisions, the company couldn’t fully utilize the speed, capabilities and potential of its new high-end machine. That’s when Mr. Grangetto and Mr. Taylor decided to give Hypermill a try.

For instance, five-axis machining greatly improves part precision by eliminating alignment errors that are introduced in standard machining when a part is removed and refixtured in another orientation. It is also extremely time-efficient, because most or all of the work is performed in a single setup with no delays while waiting for an operator to unload, reload and reposition the part.

Stepping through the tool path to watch it remove material and verify that it clears the machine without any collisions is a valuable time-saver. “I do not have to walk out to the shop floor and manually look inside a machine with coolant flowing to check clearances,” he says.

By controlling the amount of volume or the angle of the cutter’s engagement, the cutter can loop into a corner. The Maxx Machining roughing module extends tool life, and machining time is reduced by 30 to 75 percent by maintaining a constant chip load, Mr. Levine says. 5th Axis can use Hypermill Maxx Machining on materials ranging from aluminum to hard materials like Inconel because its high-speed machines are fast enough to keep up with the rapid toolpath motion that is generated. “The bottom line is that using Hypermill Maxx Machining results in super-efficient and fast tool paths,” Mr. Norton says.

Open Mind uses internal experts to develop postprocessors, which it considers to be a core technology of the company. The customized postprocessors have configurable parameters that enable users to control their particular environments. This means that the core mathematics and the basic structure of the post are created and locked down by Open Mind, but 5th Axis can change certain parameters, which influence the locked portion. According to Mr. Levine, “Some companies give the customer a tool kit and the ability to build their own post, but those guys are not there to write postprocessors; they are there to cut metal. Also, writing the entire postprocessor is too much for the original equipment manufacturer that has to ensure compatibility with various CAM software products. An alternative approach is to give the customer no control, but then they would have to call back to the service supplier to make custom changes. Our combination of locked and open is not entirely common, and we believe it gives customers the best of both worlds.” The high-quality tool paths, advanced CAM software capabilities, postprocessor support and skilled technical support give 5th Axis the confidence to take on ever more challenging jobs that require programming complex parts, Mr. Taylor says. “With Open Mind’s help, we never burn money getting stuck on a job. Their contribution has been a really big part of the growth of our business.” |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed