NTK introduces TFX Front Turning Carbide Inserts with up to 0.197" Depth Of Cut in a Single Pass12/11/2019 NTK Cutting Tools’ TFX front turning carbide inserts, designed for Swiss-type CNC applications, machines large depths of cut ranging to 0.197" (5 mm) in a single pass. The inserts incorporate a chip-breaker with a sharp cutting edge to optimize chip control and surface finishes. The inserts are available in DM4 (for titanium, cobalt chrome, heat resistant alloys and stainless steels) and ST4 (for stainless steels like 304 and 17-4PH). TFX front turning carbide inserts (wiper style available) with up to 0.197" depth of cut in a single pass, incorporate a special chip-breaker with sharp cutting edge for chip control and surface finishes. Pairing the inserts with a coolant-through holder can improve chip evacuation, surface finish, part tolerance and tool life, says the company. The company’s corresponding TFT series holders have rigid side screw clamping to ensure stable turning by preventing movement of the insert from Z directional cutting forces. TFT series holders have rigid side screw clamping for stable turning, preventing insert movement from Z-directional cutting forces. Pair the TFX inserts with a coolant-through holder (TFT...-OH2) to improve chip evacuation, surface finish, part tolerance, and tool life. The -OH2 style holders are compatible with new coolant-through gangs (Citizen L20 & D25 CNC machines). TFX inserts are available in DM4, for titanium, cobalt chrome, heat resistant alloys, stainless steels, and now in ST4, a super- tough PVD-coated carbide grade. The CrAlN coating provides high hardness and resists oxidation, solving issues related to machining materials such as 304SS, 17-4PH, and Nitinol.

0 Comments

We are very excited to announce that effective October 1, 2017 we will be representing Precision Cutting Tools Inc. in the California and Nevada market areas. Precision Cutting Tools Inc. was founded in 1963 and ever since has specialized in the production of high-quality cutting tools. Today, with over fifty years of experience, PCT is a leading cutting tool manufacturer that distributes its products all across the United States and Mexico. They have based their company’s success on their long-standing commitment to satisfy our customers’ needs, by utilizing the finest raw materials, introducing innovative cutting tools and providing excellent customer service. We look froward to working with them to develop new Carbide, Cobalt & Powdered Metal end mill and drill substrates and geometries that will meet the material cutting needs we find uniquely on the West Coast. We think you are in for a a real treat once we see what we're working on with PCT!!! Farewell & Parting: Next Generation Tooling ends relationship with MA Ford after 22 years.9/29/2017 After 22 years, Next Generation Tooling has ended our relationship as an independent sales agent for MA Ford in the Northern California and Northern Nevada territories. Our last effective day will be September 30, 2017.

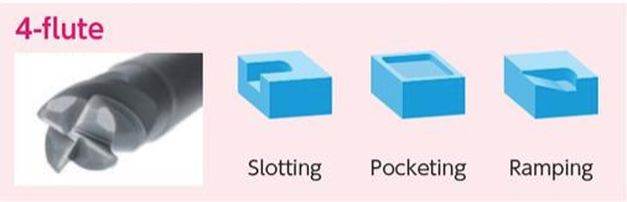

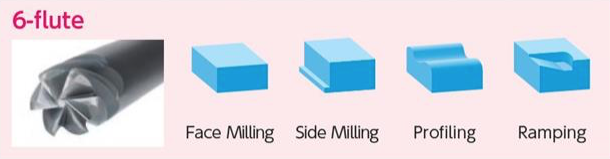

We truly appreciate and greatly value our long, successful relationship fostered by both MA Ford and NextGen since the inception of our company. We realize, with no reservation, that the wonderful people at MA Ford were a huge part of our success by working with us to develop technical solutions and will always value our memories and our personal friendships. At the outset of our relationship in the late 1990's, we worked hand-in-hand with MA Ford to introduce their products to the unique applications and high speed machining that takes place in our markets. In conjunction with the MA Ford engineering team we developed the 138 series end mills for use in aluminum and non-ferrous milling. As a result, many other end mill manufacturer's followed in the footsteps of that tool and began developing material specific tooling. Because of the unique needs of our market, we suggested the expansion of LOC and OAL from what was commonly offered in "Stub, Standard, Long & Extra Long" lengths. The 138 series end mills where the first nationally recognized brand to offer 7 different lengths of cuts as stock standard. We are very grateful to everyone at the MA Ford team who has worked with us hand-in-hand for so many years, and wish only the best for MA Ford in the future. NTK's industry leading line of ceramic cutting tools is expanding with new solid ceramic end mills. It's time to upgrade from carbide to this unique "SX9" SiAlON end mill which increases productivity more than 10 times over traditional end mills when machining Heat Resistant Super Alloy (HRSA) materials. NTK's durable SX9 grade can run at speeds of 2000 SFM. The line-up includes 4 and 6 flutes in inch and metric versions. The NEW SX9 SiALON Ceramic end mills are available in both a 4 flute and 6 flute configuration and can be used for slotting, pocketing, ramping, face milling, side milling and profile milliing. Contact a Next Generation Tooling Regional Manger for more information or for an on-site demonstration. For more infomation abotu machinginig parameters please see:

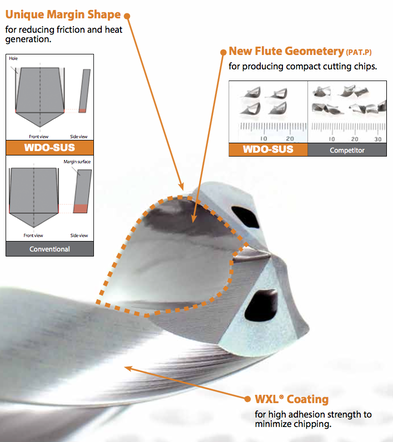

General Guidelines for Successful Milling with NTK Ceramics The new OSG WDO-SUS drill was released on Monday, June 1 2015 and we really can't say enough good things about it already! It's a game changer!

What makes it different:

Bottom line…this drill has a very smooth cutting action that allows it drill more linear inches than the competition and already our initial testing indicates that it improves the tool life of the threading tools and/or reamers that are used to finish the drilled hole. To say that we have been impressed in the first few days of testing is an understatement. You gotta run this one! OSG will be running a promotion on this tool starting in July and running through August so you WILL want to contact us now to figure out where you can use it and then take advantage of the introductory promotion starting in July. Call us now to schedule an appointment for a test

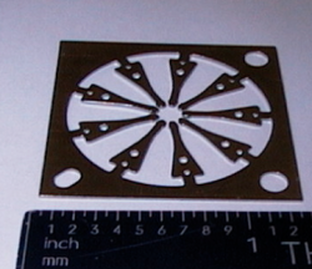

During our testing of these parts, the entire production run of these parts was place a container and run through the sPINner for 2 minutes.

The sPINner does not damage even the most delicate parts, so no parts were lost due to bending. Also, the cycle time of 2 minutes for the entire lot was drastically less that the many days it took with manual methods. Lastly, all the parts were fully deburred as the sPINner does not miss areas. All areas of the part are affected equally. This customer has purchased two sPINners to meet a growing production demand. Visit Earth Chain for more details. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed