|

A leap forward in shrink-fit technology by Bernard Martin Platinum Tooling has introduced the Rineck Induktherm Rapid Shrink II VCS Machine to its repertoire, promising a paradigm shift in the way machining professionals approach shrink-fit tooling. In this article, we'll explore the key features, benefits, and applications of this cutting-edge machine that has garnered attention in the manufacturing industry.

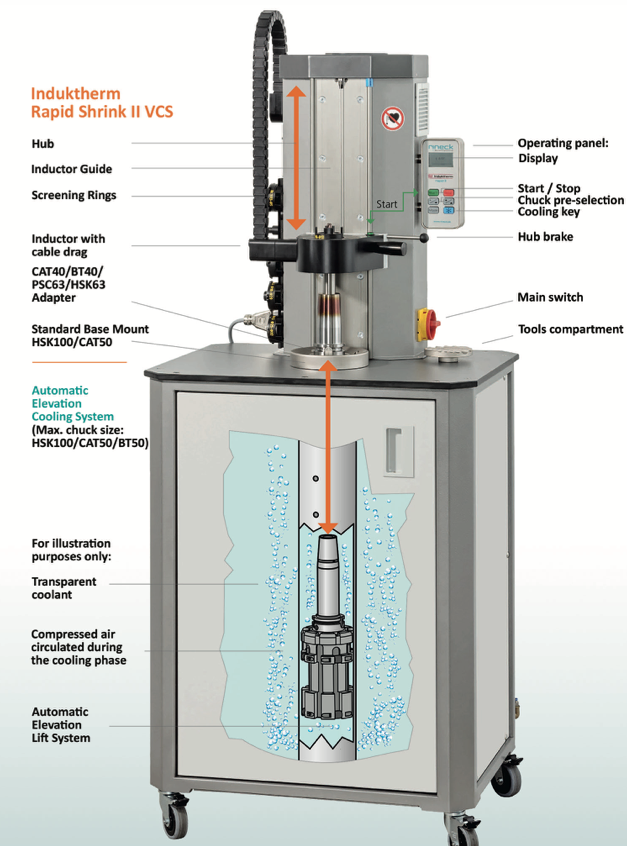

Key Features of the Rineck Induktherm Rapid Shrink II VCS Machine: Rapid Heating Technology The Induktherm Rapid Shrink II VCS Machine is equipped with rapid heating technology, ensuring swift and efficient tool heating. This feature significantly reduces downtime and enhances overall operational efficiency. The heating time takes only between 3 – 9 seconds! Versatile Cooling System (VCS) The VCS system integrated into the machine allows for both air and water cooling, providing flexibility based on the specific requirements of different tools and materials. The cooling time varies between 15 and 50 seconds depending on the mass of the tool holder. User-Friendly Interface The machine boasts a user-friendly interface, making it easy for operators to navigate and control the heating and cooling processes. Intuitive controls contribute to a seamless user experience. Precision and Consistency The Induktherm Rapid Shrink II VCS Machine ensures precise and consistent tool clamping, critical for achieving accuracy in machining processes. This level of reliability is essential in applications where tolerances are tight. It's designed for use with HM tools with shafts of Ø 3 to Ø 32 mm and HSS tools of Ø 6 to Ø 32 mm Compact Design Despite its advanced features, the machine maintains a compact design, making it suitable for various workshop environments. Its space-saving attributes make it a versatile choice for machining facilities of different sizes. Benefits and Applications

0 Comments

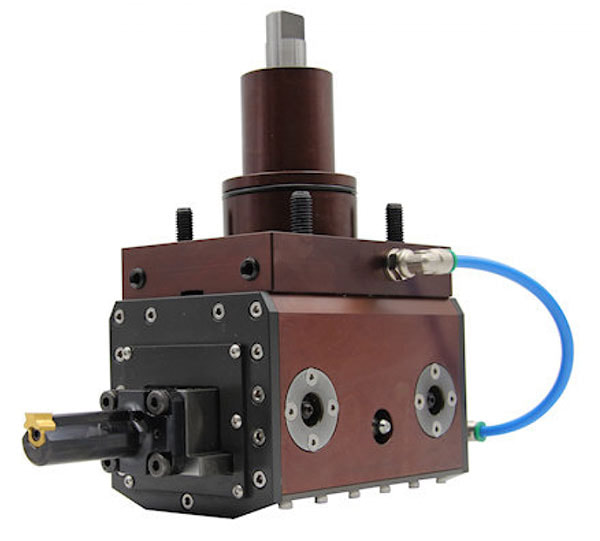

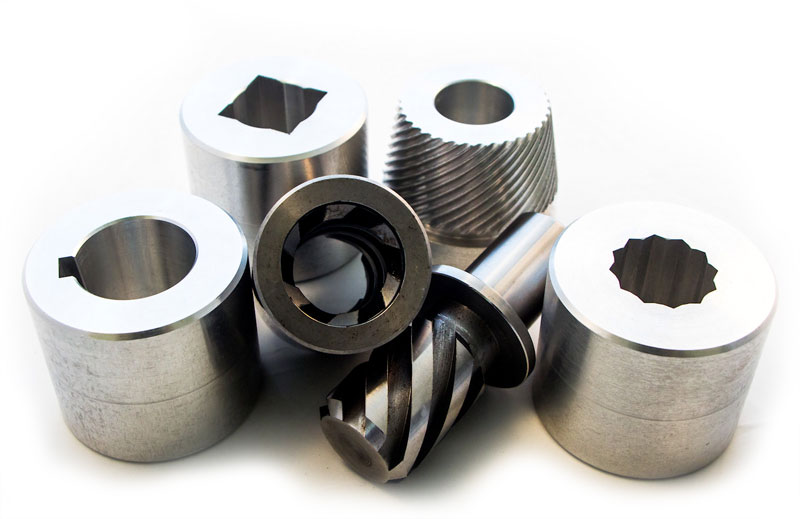

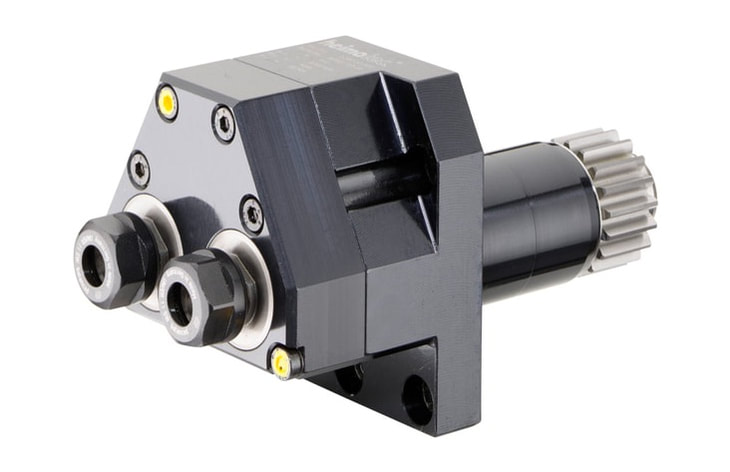

Are you looking for new ways to machine keyways? What about internal or external teeth or spline? Platinum Tooling has you covered with the Rev Broaching Tools for CNC lathes & Machining Centers. REV S.R.L., located in Northern Italy, is the manufacturer of innovative broaching solutions for CNC Lathes and Machining Centers. Ideal for machining simple keyways or internal and external profiles, both teeth and splines. Common profiles including square and hexagon are easily achieved; custom profiles are available. Platinum Tooling offers innovative broaching solutions from REV S.R.L. for both CNC Lathes and Machining Centers. All REV broaching tools offer excellent performance with long insert life and high surface quality. A wide variety of standard and custom profiles and sizes are available.

The REV System for CNC Lathes and Machining CentersStandard and Custom ProfilesA wide variety of standard and custom profiles and sizes are possible with REV broaching tools

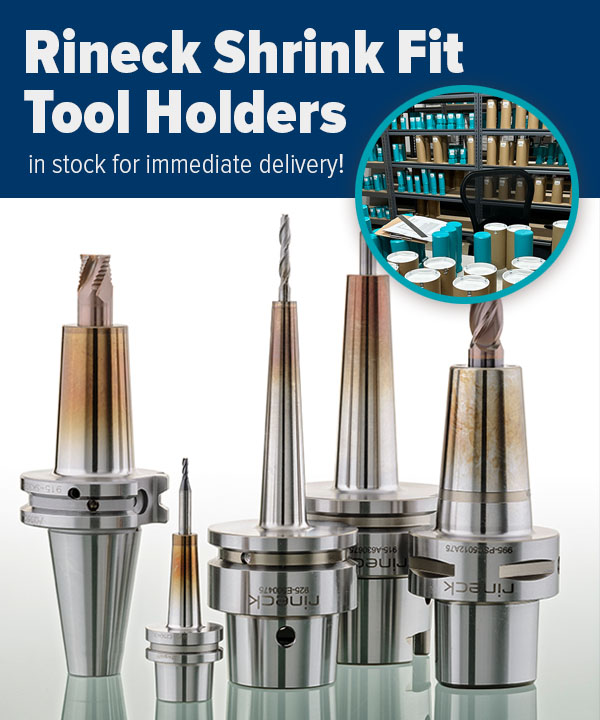

Platinum Tooling now inventories a wide selection of Rineck Shrink Fit Tool Holders in the most common styles and sizes at thier headquarters in Prospect Heights, Illinois. These high-quality German made tool holders are produced for high accuracy and maximum rigidity.

Stock tools are available in imperial (inch) and metric sizes with slim 3° and standard 4.5° execution with the following machine connections:

For more information on Rineck Shrink Fit Tool Holders or any of our other precision machine tool accessory lines, contact us!

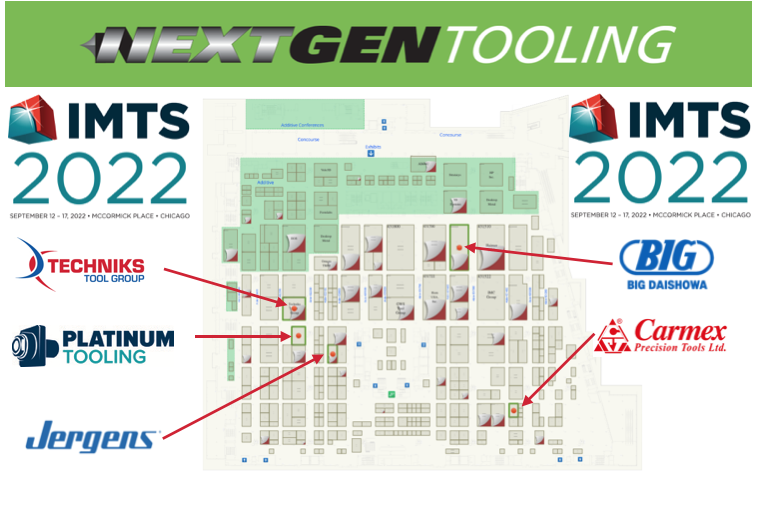

Cutting Tool Engineering visited Preben Hansen, President of Platinum Tooling Technologies Inc., at their IMTS 2022 booth. Preban highlighted some of the features a variety of products from Heimatec, Tecnicrafts, Quick, Henninger and Rineck.

Take a look at the video and let us know if you have any questions. Here's a look at some of the new products and special offers from our manufacturers! You'll want to check them out in-person at the show, on-line during the show or contact us and we can stop in and get into the details at your shop with one of our guys. BIG DAISHOWA High-Performance Tooling SolutionsBIG DAISHOWA designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, military, aerospace, energy, and micro-technology industries. BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system Be sure and check out the two special offers:

Carmex Precision Tools, LLCCarmex Precision Tools specializes in carbide cutting tools for thread turning & thread milling. They will be showcasing a full line of tools for Swiss machines, including turning, back turning, grooving & parting. Jergens, Inc.Jergens Inc is a global manufacturing leader of CNC machining custom workholding products. Today, you'll find their vises, clamps & fixturing systems, tooling components, at work in just about every segment of the metalcutting industry. Check out their innovative engineered solutions like the patented

Platinum ToolingPlatinum Tooling has been hard at work searching to find the highest quality machine tool accessories in the market…and we think they’ve done it! Platinum Tooling will be showcasing the following products at IMTS:

Techniks Tool GroupTechniks Tool Group (TTG), the parent company of Techniks and Parlec, is one of North America’s largest providers of best-in-class tooling solutions for CNC machining centers. Check out the complete list of products they will be demonstrating at IMTS:

The exclusive importer of Heimatec live and static tools, Platinum will offer 1:4 speed increasers for most Citizen machine models. Platinum Tooling Technologies, Inc., the exclusive importer of Heimatec live tools, angle heads, and multi-spindle heads, is excited to announce their extended product offering to the current Citizen tool program.

In addition to the standard live and static tools, they will offer 1:4 speed increasers for the most current Citizen machine models. Designed to optimize the machine’s parameters, these precision tools are efficient and cost effective. Originally developed for the manufacture of precision parts in the watch industry, Swiss-type CNC Automatic Lathes are now widely used throughout the industry to produce automotive components, screws and pins for the medical industry, and precision parts for electrical engineering. Platinum Tooling and Heimatec’s goal during the development of this line was to construct a series of tools that would offer the greatest possible processing quality and longest service life, while additionally enhancing the machine’s capabilities with the use of speed increasers. To achieve this, Heimatec incorporates the highest quality bearings, ground gear components, spindles, and housings to produce superior tools with maximum rigidity. In addition to Citizen, Platinum Tooling is constantly striving to expand their tooling programs to include superior quality products to enhance machining operations, increase productivity, and create cost savings opportunities. Hommel + Keller QUICK Line of Knurling & Marking Tools Added to the Platinum Tooling Family7/13/2022 Platinum Tooling is excited to introduce the Hommel + Keller QUICK line of Knurling & Marking Tools. These quality, precision tools are a perfect complement to Platinum Tooling's existing machine tool accessory lines. Knurling Tools The QUICK product line offers innovative solutions for diverse cut & form knurling applications. These tools are available for use on a wide range of workpiece diameters including small tools for Swiss type lathes. Marking Tools

The QUICK marking tools make it possible to mark workpieces with a variety of geometries in a matter of seconds. These tools are customizable and available in 2 different size diameters. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed