|

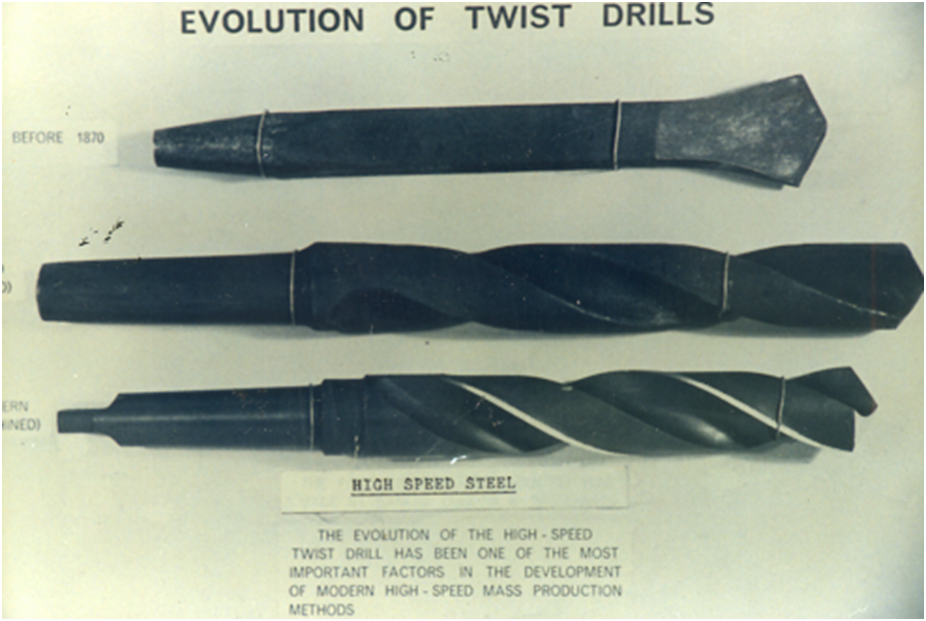

Next Generation Tooling is excited to announce that we have been chosen as he exclusive agent for Northern California and Nevada by Somta Tools. In December 2016, OSG partnered with Somta Tools (Pty) Ltd. Founded in 1954, SOMTA is South Africa’s largest manufacturer of round cutting tools including Drills, Reamers, End Mills, Bore Cutters and Taps which are available in a wide range of sizes using various materials and quality surface coatings to extend tool life. Somta Tools HistorySomta Tools was founded in 1954 by Samuel Osborn Ltd of Sheffield, England. The name Somta is an acronym derived from the names of Samuel Osborn (founder of Osborn Steels U.K.), and Robert Mushet (the 19th century inventor of High Speed Steel). The full name is actually Samuel Osborn Mushet Tools Africa. Somta started out producing Twist Drills, Reamers, Toolbits and Chisels with a complement of about 20 employees. Somta Tools Mission is to manufacture and supply superior cutting tools, driven by a culture of service excellence, to global markets. One of Somta’s claims to fame is that its former parent company produced the first Twist Drill made from High Speed Steel. Prior to 1870, twist drills were made from a flat piece of steel and then physically twisted, hence the name. Thereafter the flutes were produced on milling machines until the grinding method arrived. One milestone worth a mention is when Somta Tools purchased a Hertlein drill flute grinding machine in 1963, even before the parent Sheffield company bought one. This machine is still in operation today. This machine grinds the flutes of a drill (up to 13mm diameter) in one pass in a solid hardened blank. This was unheard of in those days. Growth at Somta: 1963 – 1999Somta gradually grew in both output and number of employees. Numerous products were added to the range during this period. In 1979 the company was purchased by Haggie Ltd, one of the largest steel rope manufacturers in the world. The South African mining sector was their biggest market. Continued Growth at Somta Tools in the 1980’s With Haggie as its owner, Somta progressed and accelerated its growth. This was achieved by investment in capital equipment and by acquisition. Introduction of Friction Welding (HSS body, EN9 shank) Somta Tools introduced friction welding in 1980, the first cutting tool company to do this outside of the UK. Introduction of CNC Grinding Machines In the early 1980’s, CNC grinding machines were being developed in the USA and Europe for this industry. Somta purchased a number of these machines. This technology ensured greater consistency in quality and enabled Somta to enter and compete in world markets. Clarkson & Mitco Acquisition Somta Tools acquired Clarkson Tap and Die South Africa (conveniently located next door) in 1982 and Mitco Tools Pietermaritzburg in 1984. Clarkson had about 60 employees and Mitco about 160. The Mitco premises were closed with all of the employees and machinery moving to the present Somta site at Edendale Road. Factory Expansion & Divisions Working space was at a premium with so many more people and additional equipment. It was therefore necessary to extensively add factory space. It was decided to establish separate factories for product types, for instance Steel Stock and Blank Prep, Drills, Taps, End Mills and other factories. Each factory had its own manager who was responsible for hiring staff, training, quantity, quality, cost etc. This occurred in 1986 and this concept remains today. The employees in each factory became product specialists. Change of Ownership: 1999 – PresentIn 1999 Haggie decided to ‘unbundle’ its non-core or non-mining related companies, of which they had quite a few. Somta was then purchased by Brooke Industrial Holdings in the UK. Unfortunately Brooke ran into difficulties in 2003 and went into liquidation. Somta Tools then underwent a management buyout largely funded by the SCMB (Standard Corporate Merchant Bank). US $2M Investment in Balzers Coating Plant: Immediately after the MBO in 2003, Somta Tools integrated a state of the art Balzers PVD Rapid Coating System into it’s manufacturing programme, offering the innovative range of Balzers BALINIT® high performance coatings on all cutting tools. This has enabled Somta to offer coated cutting tools to compete with the very best high tech tool producers in the world.

Somta Workers Get 7.5% Stake In late 2010, Somta Tools launched an empowerment initiative through the establishment of the Somta Employees’ Trust, which gave the company’s 500 employees a collective 7,5% stake in the company. This all came about when management bought-out, and restructured the company, from its main shareholder, SCMB (Standard Corporate Merchant Bank). The deal was part of the company’s broad-based black economic empowerment strategy in its attempt at initiating its own “African Renaissance” with the aim of making employees feel like they are part of something great. Carbide Production Facility Expansion In 2012 Somta Tools invested over ten million rand that year alone on state-of-the art CNC equipment, which saw the company quadruple its carbide tool manufacturing capacity, thereby improving delivery times. Included in this investment was a Walter Helicheck Basic 3, for non-contact complete measurement of rotationally symmetrical precision tools with complex geometry, which significantly improves quality and inspection procedures as well as 7 other machines with a further 3 to be added. This expansion allowed for a dedicated test and training facility which included the addition of a HAAS VF-3YT CNC vertical machining centre, to test, run and enhance current and new tool designs, as well as for training purposes. Somta Tools can now utilize its state-of-the art R&D facility to find solutions to difficult machining applications or material types. SOMTA is able to simulate the production conditions so that their customers no longer have to break into critical production lines to conduct testing. No other facility on the African continent boasts the combined manufacturing, measuring, coating and testing capabilities. Company StatisticsProduct Distribution Somta Tools has about 370 distributors in South Africa making it the market leader. Somta exports to 70 countries around the world. 58% of sales are to the export market. Somta sells to distributors, catalogue houses and a number of other cutting tool manufacturers worldwide. Product Range Today Somta Tools offers 7 000 standard items, and a further 3 000 made-to-order items, to DIN, ISO, ANSI and JIS standards, as well as custom tools to drawing. Staff Complement

Somta Tools currently employs more than 400 people in total, which includes the Johannesburg sales office and warehouse. Factories Somta Tools has separate factories for Blank Prep, Heat Treatment, Drills, End Mills, Taps, Reamers, Specials, Carbide and Coating all on one site. Company Vision A world class provider of cutting tools. This vision is supported by being ISO 9002 which was achieved in 1991 and ISO 9001 in 2003 and 2008.

1 Comment

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed