Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations.

0 Comments

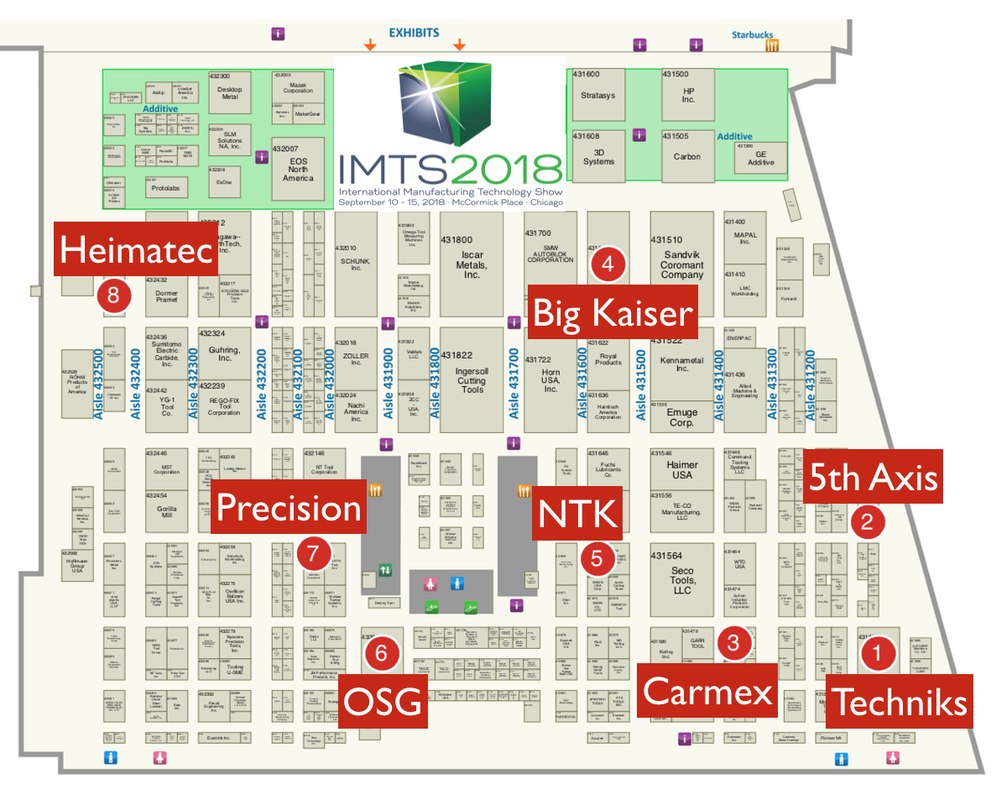

Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075  David Edge David Edge We are very excited to announce that David Edge has joined the Next Generation Tooling team. David has a wealth of experience from his 45+ years in the metalcutting industry. He not only knows the technical aspects of cutting tool applications but also the procedural functions that are important to manufacturers, Industrial distributors and machinery dealers. David began his career in 1972 as a manufacturing engineer in turning applications, with Pneumatic Auto Turret lathes, Tracer lathes and manual Turret lathes. He cut his teeth in sales for 11 years as a cutting tool specialist for Valenite in the Bay area. He moved north to work for RTW and Iscar where he managed Washington, Oregon and Western Canada for the many aerospace applciations in that area. In 2012 he moved back to the Bay area to manage Northern California for Tungaloy. David also brings first hand experience as a distributor from his time at J&L Industrial Supply and Aronson-Campbell Industrial Supply as a carbide application engineer. He has a deep understanding of what the expectations are of a industrial distributor from a manufacturer. David also has an inside knowledge of the expectations of a machine tool dealer from his time back in the late 1980's working at Selway Machine Tools.

We where very excited to meet and greet many of our customers at the 2017 Western Tool & Supply Open House. It was held at their San Jose, CA. on September 21- 22, 2017. We featured quite a few featured products from our principals during the two day event. It was great discussing lots of technical applications that machinists brought to us! The International Manufacturing Technology Show is one of the largest industrial trade shows in the world, featuring 1,900 exhibitors and 100,000 visitors. The event is held every two years in September at McCormick Place, Chicago.

Don't miss out on the biggest show in Manufacturing - Register today! On-site registration is open Monday, Sept. 12 through Saturday, Sept. 17 in all four buildings of McCormick Place. Tooling & Workholding Systems Pavilion in the West Building is open 9:00 a.m. - 5:00 p.m. Several of our Principals will have products on display at IMTS 2016. Below is where you can find them at the show.

Pavilion: Tooling & Workholding Systems

Let us know if you're attending and let's make plans to meet each other in Chicago! Please welcome Matt Smith to the Next Generation Tooling Team! We are very pleased to announce that Matt Smith has joined our team.

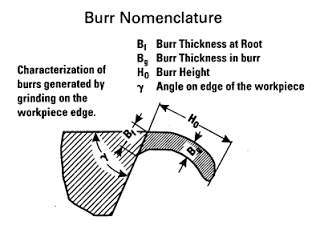

What kind of burr can the sPINner remove? We are often asked, “What kind of burr will the sPINner remove?” The standard answer is “a light burr”. This answer leaves a lot of room for interpretation. What is a light burr to some will be a heavy burr to others. The rule of “Thumb”: In order to form an initial evaluation if the sPINner will work on a particular part try the rule of “thumb”. As a general rule, if you can take a fingernail and remove the burr, the part has a good chance of testing well in the sPINner. Burrs heavier than this may tend to roll and flatten, but not be removed during the process. A quick lesson on burrs: Light Burrs

A lighter burr can be loosely defined as a burr with a thin thickness at root (B1). As the amount of material holding the burr to the parent metal increases, a more aggressive deburring action is required to remove the burr. Using this definition it is possible to have burrs that are tall, yet are “lighter” by our definition because the thickness at the root is small. Burrs of this type are good candidates for the sPINner. Short Heavy Burrs An example of short, yet heavy burrs are the ridges created from drilling. When a drill breaks through a part a ridge is pushed up around the hole on the side where the drill breaks through. While this ridge can be short in burr height (H0), the thickness at burr root is wide. Often this material is more a part of the parent metal than the burr. These burrs will not be good candidates for the sPINner as a very aggressive and abrasive action that has a high stock removal rate is required to remove these burrs. Brittle Materials Another factor to weigh in this process is the material itself. More brittle materials will tend to have the burr break away from the part (parent metal) making the sPINner a good option. Softer Materials Softer or more malleable material will tend to have the burr roll and flatten. Softer materials need to have a thinner thickness at root to be good candidates for the sPINner. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed