|

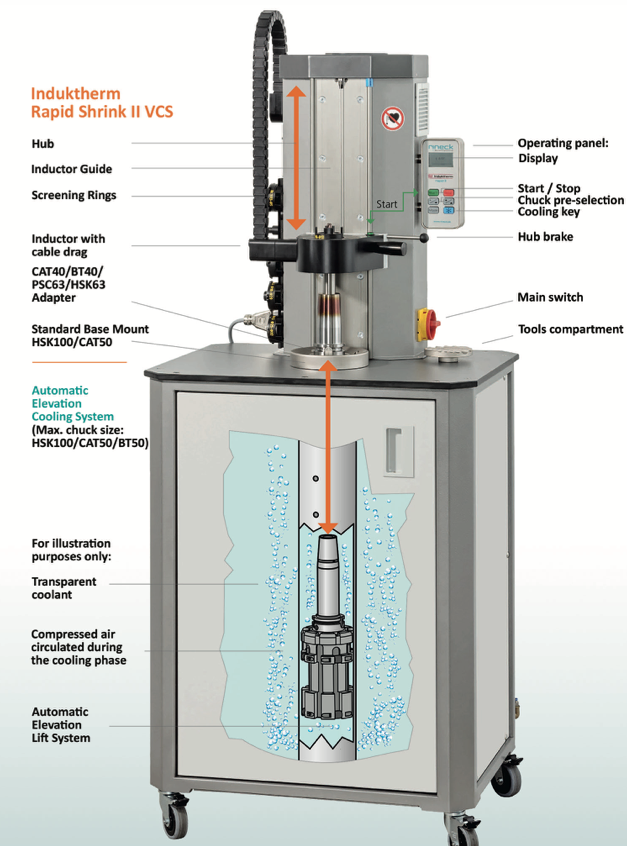

A leap forward in shrink-fit technology by Bernard Martin Platinum Tooling has introduced the Rineck Induktherm Rapid Shrink II VCS Machine to its repertoire, promising a paradigm shift in the way machining professionals approach shrink-fit tooling. In this article, we'll explore the key features, benefits, and applications of this cutting-edge machine that has garnered attention in the manufacturing industry.

Key Features of the Rineck Induktherm Rapid Shrink II VCS Machine: Rapid Heating Technology The Induktherm Rapid Shrink II VCS Machine is equipped with rapid heating technology, ensuring swift and efficient tool heating. This feature significantly reduces downtime and enhances overall operational efficiency. The heating time takes only between 3 – 9 seconds! Versatile Cooling System (VCS) The VCS system integrated into the machine allows for both air and water cooling, providing flexibility based on the specific requirements of different tools and materials. The cooling time varies between 15 and 50 seconds depending on the mass of the tool holder. User-Friendly Interface The machine boasts a user-friendly interface, making it easy for operators to navigate and control the heating and cooling processes. Intuitive controls contribute to a seamless user experience. Precision and Consistency The Induktherm Rapid Shrink II VCS Machine ensures precise and consistent tool clamping, critical for achieving accuracy in machining processes. This level of reliability is essential in applications where tolerances are tight. It's designed for use with HM tools with shafts of Ø 3 to Ø 32 mm and HSS tools of Ø 6 to Ø 32 mm Compact Design Despite its advanced features, the machine maintains a compact design, making it suitable for various workshop environments. Its space-saving attributes make it a versatile choice for machining facilities of different sizes. Benefits and Applications

0 Comments

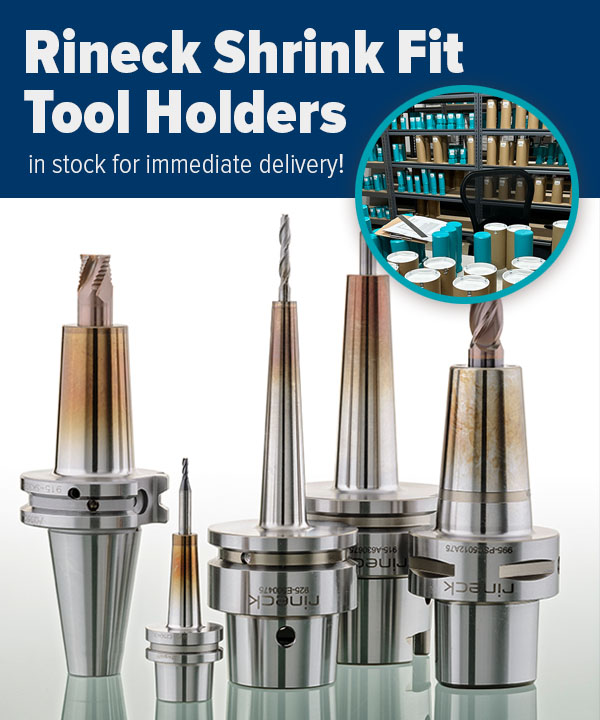

Platinum Tooling now inventories a wide selection of Rineck Shrink Fit Tool Holders in the most common styles and sizes at thier headquarters in Prospect Heights, Illinois. These high-quality German made tool holders are produced for high accuracy and maximum rigidity.

Stock tools are available in imperial (inch) and metric sizes with slim 3° and standard 4.5° execution with the following machine connections:

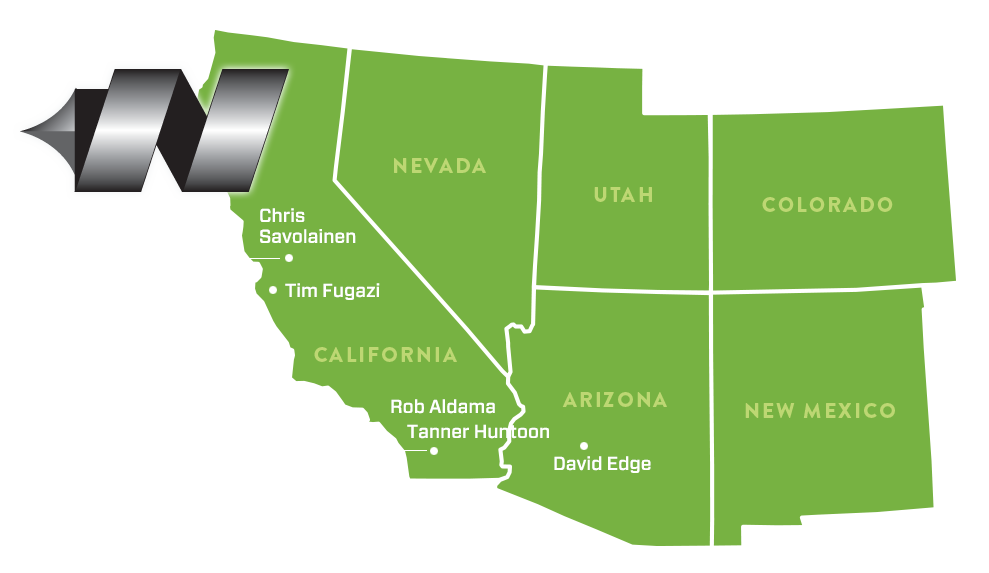

For more information on Rineck Shrink Fit Tool Holders or any of our other precision machine tool accessory lines, contact us! Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

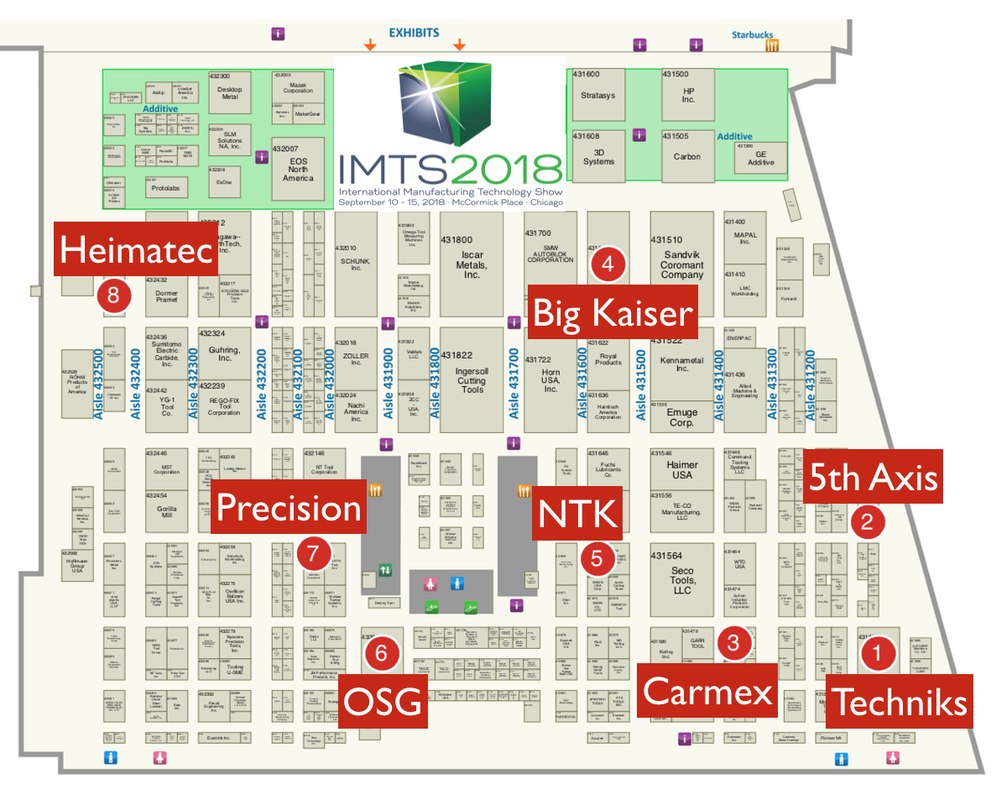

Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075 By Jack Burley Many shops are unaware that a lot of their spindles are BIG-PLUS, so they don’t realize the capabilities they possess that this system provides. If you identify these spindles on your floor and want to start taking advantage of them, there are some things you should know I was recently chatting with our friends at SPS Spindle Parts and Service, LLC (Goffstown, NH). They are, to my understanding, the only certified BIG-PLUS® spindle grinder in America that performs onsite regrinds. Chris Vigneault, their onsite grinding manager, explained that most of their onsite visits, BIG-PLUS or not, are the result of a crash or poor drawbar retention that allows a tool to loosen in the spindle. That isn’t usually surprising news, but Vigneault explained that their testing and examination process often does reveal something else that is very surprising for customers: “One of the things that most customers are unaware of is that a lot of their spindles are BIG-PLUS and they simply don’t know it,” he said. “Not all, but a lot of customers lately are looking for that ability and just don’t know that they already have it.” This is common after the purchase of a used machine tool, but shops are even more surprised when they hear this news about new machines. There are a couple of reasons this happens:

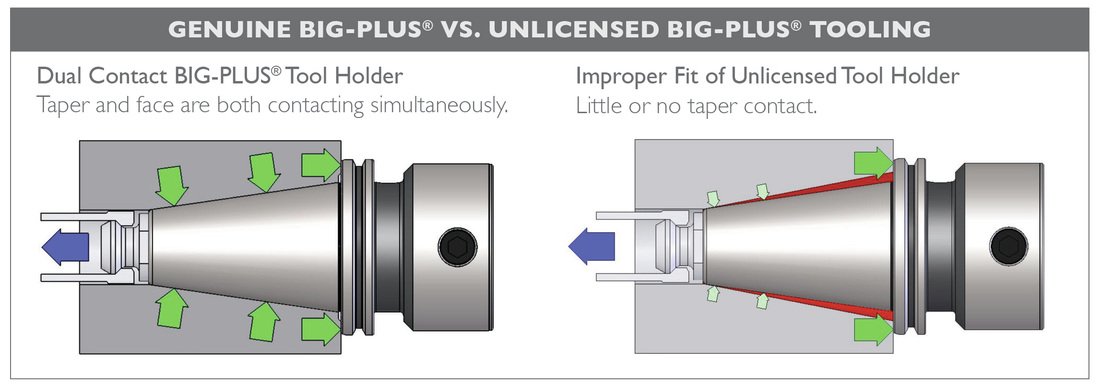

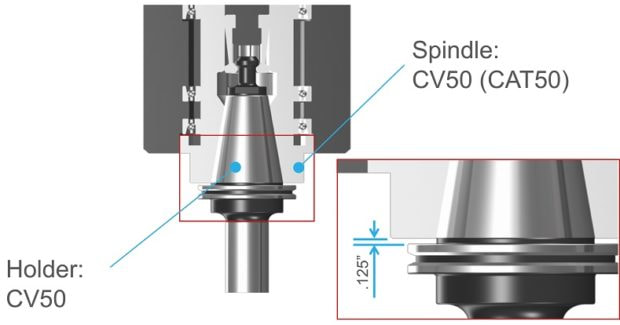

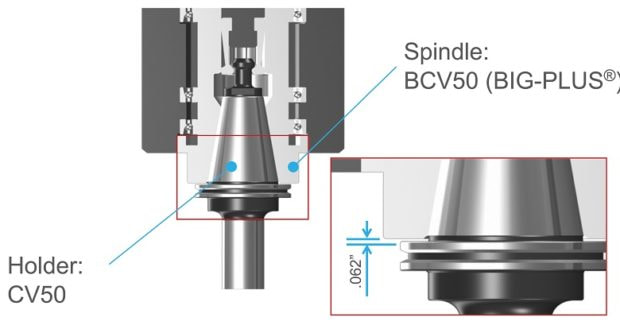

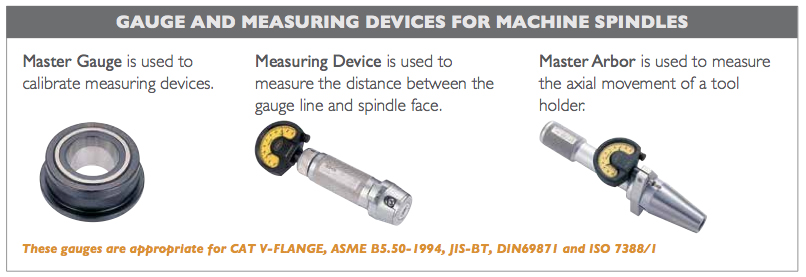

All of which begs the question, how do you find out if you have a BIG-PLUS spindle? We have learned over the years which builders are making their spindles to BIG-PLUS as a standard or as an option, and on which models. So when I visit a customer or talk to them over the phone, I ask what brands of machines they use and compare this with the master list of authorized machine tool builders for BIG-PLUS. However, the easiest way to figure it out is to place a standard tool into the spindle and see how much of a gap there is between the tool holder flange face and spindle face. Without BIG-PLUS, the standard gap should be visible, or about .12 in. If it is BIG-PLUS, the gap is half of this amount, or only .06 in. These values change depending on 30 taper, 40 taper or 50 taper sizes, but the gap is visibly less than usual. If you identify BIG-PLUS spindles on your floor and you want to start taking advantage, there are some things you should know. First, if you’ve been using standard V-flange tools in that spindle, you likely won’t be able to realize the full benefits of the system. Over time, standard tooling will wear the spindle in ways that change its geometries. “We were just at a shop in Connecticut checking out a BIG-PLUS spindle,” recalled Vigneault. “Because of the way it wears when you don’t use BIG-PLUS tooling – which is exactly the way this customer was using the machine – the face was very heavy, or oversized. If we were grinding it back into spec, it would probably take quite a bit of work. We would have to take a lot of material off the face to get there.” Because both taper and face contact are what make the system shine, the geometry is critical. If someone trying to transition to BIG-PLUS tooling after learning they have the spindle doesn’t understand that, they won’t experience the performance they expect. There’s also the factor of maintenance. If a shop didn’t know it had BIG-PLUS machines, it’s a safe bet they didn’t take the preventive steps to help preserve the crucial geometry. These include keeping the spindle, tools and carts clean; misaligned automatic tool changer arms can also harm a BIG-PLUS spindle. These very reasons are why we offer spindle and tool taper cleaners, as well as arm alignment tools. Also, resist the temptation to use less expensive, unlicensed dual-contact tools if you want to give the system a shot. These tool makers do not have the master gauges necessary to create the correct geometry . . . for reference, read my Depth of Cut column titled “Is BIG-PLUS an International Standard?” It shares comparative test results and details the risks. There’s really one proven way to restore a BIG-PLUS spindle to proper specifications: with a certified regrind. Just as tool makers need the right gauges and measuring devices, so do spindle grinders. If you discover you have BIG-PLUS spindles and want to take advantage, keep these factors in mind to see what the system can do. Jack Burley is the vice president of sales and engineering at BIG KAISER Precision Tooling Inc., 2600 Huntington Boulevard, Hoffman Estates, IL 60192, 847-228-4011, Fax: 847-228-0881, [email protected], www.bigkaiser.com. More and more, we are asked this fairly simple question from shops who want to purchase BIG-PLUS® dual contact tooling from sources other than us. One would certainly think that this must be the situation, given that more than 100 of the world’s top selling machine tool builders have adopted the BIG-PLUS spindle system as their own standard. The truthful answer to anyone who asks is that this system has not been standardized by any governing body such as ISO, DIN, JIS, or ASME.  This comparison of licensed BIG-PLUS vs. unlicensed BIG-PLUS tooling shows how little or no taper contact in the unlicensed tool holder can allow “float” in the spindle taper with no positive radial location, causing large cutter runout and immediate fretting corrosion on that spindle face that can severely damage the spindle. BIG Daishowa, the original developer of this system and a major reason that it has been so widely accepted throughout the world, still holds all of the proprietary information and, more importantly, the grand master gages that are used for reproducing spindles and tooling. Access to this information and gaging is well protected by BIG and is only provided to those companies who acquire a license agreement, mostly to protect the integrity of the system, which uses very close tolerances in order to function at its designed performance level. The popularity of BIG-PLUS has surged over the past ten years as many shops have tried the system and have witnessed for themselves the huge benefits in higher performance and accuracy over standardized taper contact tooling systems, such as CAT or BT. Other dual contact systems, such as HSK, have also seen a rise in popularity for similar reasons, but perhaps not with all of the same benefits of BIG-PLUS. Unfortunately, all of this increased popularity and demand has been accompanied by a surge in unlicensed copies to the market that offer all kinds of promises and prices never seen before. BUYER BEWARE I cannot fault a shop for purchasing cheap dual contact tooling after being told by their supplier that it will work just as good as the originals for half the price. After all, human nature wants to find the best offer at the best price – that sort of deal is capitalism at its best. As consumers, we are all confronted with choices every day about buying similar products that do similar functions from a wide range of suppliers and costs. For me personally, I usually decide to buy cheap only when I know the product will be used one time and then thrown away. On all other purchases, I’m in it for the long haul and willing to pay higher prices. At the end of the day, I want to be confident I made the right choice for the long term, and I’m willing to pay more for my peace of mind. Master gages for tooling are quite common. Generally all of them are traceable to a known master to compare the accuracy for rate of taper for production of tool holders, such as CAT or BT. ISO dual contact systems such as HSK rely on the use of a grand master gage that all other master gages are produced to, thereby guaranteeing that all HSK tool holders are the same everywhere in the world. Our company decided to find out how the world’s leading suppliers of HSK tool holders compared to the tolerances of the ISO standard. After acquiring more than 30 HSK-A63 taper tools from our competitors from all over the world and making a detailed quality inspection of the taper itself, we found that 50 percent of the samples were not in tolerance.

What are the consequences to a poorly researched choice in BIG-PLUS tooling? Unless all of the tools are marked “BIG-PLUS® Spindle System-License BIG DAISHOWA SEIKI,” the use of tooling not made by BIG Daishowa or its licensees may result in unsatisfactory performance and/or damage to very expensive spindles. Conditions producing such unsatisfactory performance include:

Jack Burley Jack Burley is the vice president of sales and engineering at BIG KAISER Precision Tooling Inc., 2600 Huntington Boulevard, Hoffman Estates, IL 60192, 847-228-4011, Fax: 847-228-0881, [email protected], www.bigkaiser.com. by Steve McBride, Product Specialist, OSG Tap & Die There are a variety of Shrink Fit Toolholding Systems on the market, all of which use thermal contraction to grip cutting tools. However, while most Shrink Fit holders are one-piece type, OSG has improved upon this design with our “hybrid” Shrink Fit System. The word “hybrid” is defined as “something of mixed origin or composition” and this is what OSG has accomplished with our shrink fit system, as our holders have the accuracy and rigidity of Shrink Fit Holders, but the versatility of Collet Chucks.

HOW ACCURATE IS IT? Since all surfaces are precision ground, OSG’s Shrink Fit System maintains a runout accuracy of 5 microns (0.0002”) or less. This accuracy is consistently repeatable, since our Shrink Fit Collets are made of a stainless steel alloy (rather than tool steel) and our hot air Shrink Fit unit keeps the heat to a manageable level. This high level of accuracy helps the customer to machine the part to a finished state without worry.

Using the OSG’s Shrink Fit Holders with standard cutting tools (rather than EDM or special extended-length cutting tools) save customers considerable money. OSG’s Shrink Fit Collets can also be modified to fit extremely tight spaces

FLEXIBILITY In addition to accuracy and reach, OSG’s Shrink Fit System offers flexibility that others do not. One Base Holder can accommodate a variety of Shrink Fit Collets, allowing customers to keep initial investments low. Also, since Shrink Fit Collets can be used in any Base Holder, customers can use OSG’s Shrink Fit System in multiple machines simply by purchasing new Base Holders. This is particularly helpful since a shop can get greater versatility out of existing tooling when they purchase new machines. MAXIMUM COST SAVINGS OSG’s Shrink Fit System provides maximum accuracy, reach and flexibility, all of which contribute to increased productivity and cost savings. Your customers should consider our system not only for new tooling purchases, but also for improving productivity on existing jobs. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed