|

Entry-level Tool Presetting and Measuring system Big Daishowa’s Speroni STP Essentia tool presetting and measuring system performs measurements next to machine tools. The SPERONI STP ESSENTIA is the entry-level Tool Presetting and Measuring system. Its robust structure and user-friendly software interface allow customers to benefit from a basic, essential unit with a tangible, long-lasting performance. The ESSENTIA enables users to measure tools offline and has user-friendly controls designed to optimize tool measurement operations. The MaxP runout function, base post processor and entry-level tool database are included in the Essentia control. Presetters measure the cutting edges of tools to ensure they match job specifications and are ready for use in the machine. Adjustments that could take up to 15 minutes can be made offline in less than one minute on a presetter, the company says, allowing the machine to continue cutting.

With the SPERONI ESSENTIA, you can efficiently measure tools, easily and independently of the operator achieving full machining productivity. Robust, space-saving, and long-lasting, ready to deliver quality results right beside your CNC machine.

0 Comments

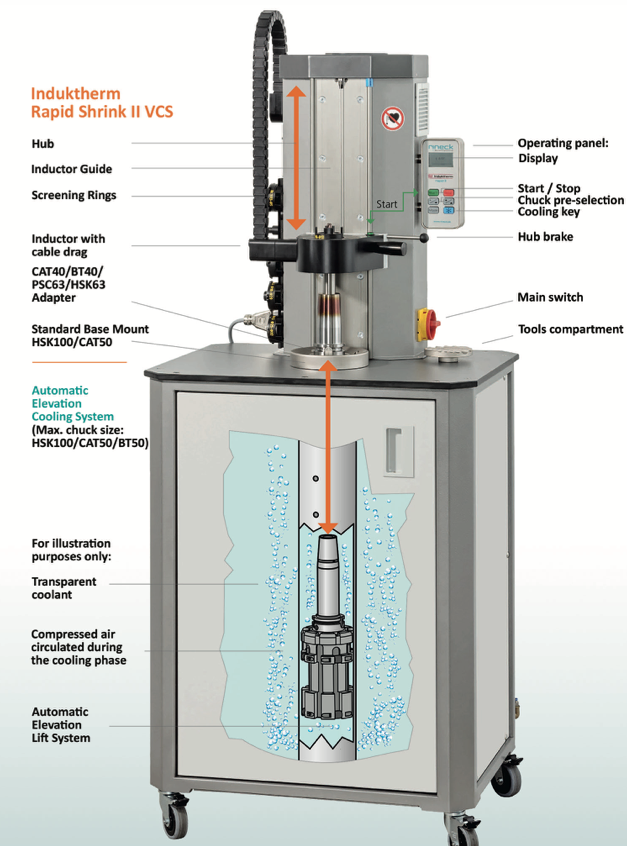

A leap forward in shrink-fit technology by Bernard Martin Platinum Tooling has introduced the Rineck Induktherm Rapid Shrink II VCS Machine to its repertoire, promising a paradigm shift in the way machining professionals approach shrink-fit tooling. In this article, we'll explore the key features, benefits, and applications of this cutting-edge machine that has garnered attention in the manufacturing industry.

Key Features of the Rineck Induktherm Rapid Shrink II VCS Machine: Rapid Heating Technology The Induktherm Rapid Shrink II VCS Machine is equipped with rapid heating technology, ensuring swift and efficient tool heating. This feature significantly reduces downtime and enhances overall operational efficiency. The heating time takes only between 3 – 9 seconds! Versatile Cooling System (VCS) The VCS system integrated into the machine allows for both air and water cooling, providing flexibility based on the specific requirements of different tools and materials. The cooling time varies between 15 and 50 seconds depending on the mass of the tool holder. User-Friendly Interface The machine boasts a user-friendly interface, making it easy for operators to navigate and control the heating and cooling processes. Intuitive controls contribute to a seamless user experience. Precision and Consistency The Induktherm Rapid Shrink II VCS Machine ensures precise and consistent tool clamping, critical for achieving accuracy in machining processes. This level of reliability is essential in applications where tolerances are tight. It's designed for use with HM tools with shafts of Ø 3 to Ø 32 mm and HSS tools of Ø 6 to Ø 32 mm Compact Design Despite its advanced features, the machine maintains a compact design, making it suitable for various workshop environments. Its space-saving attributes make it a versatile choice for machining facilities of different sizes. Benefits and Applications

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed