|

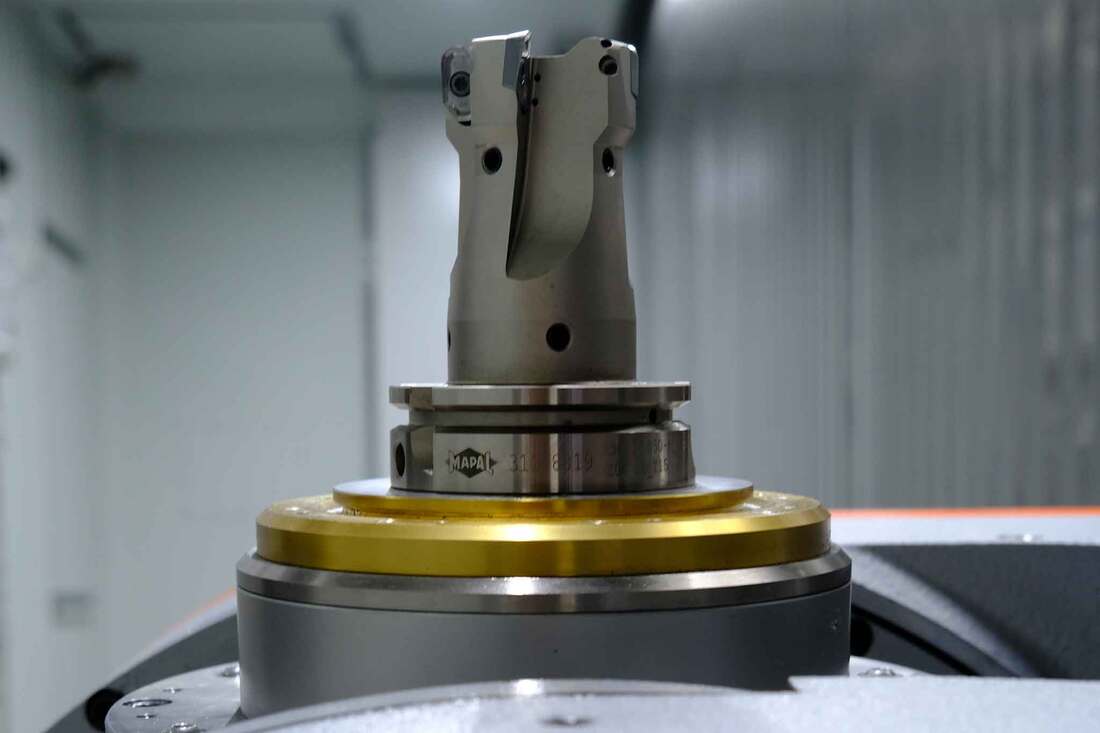

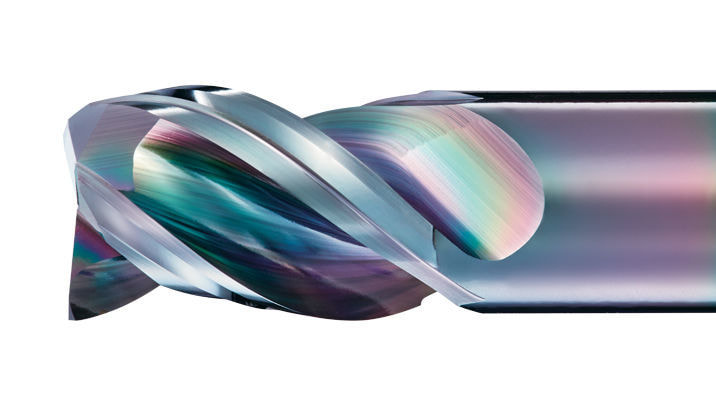

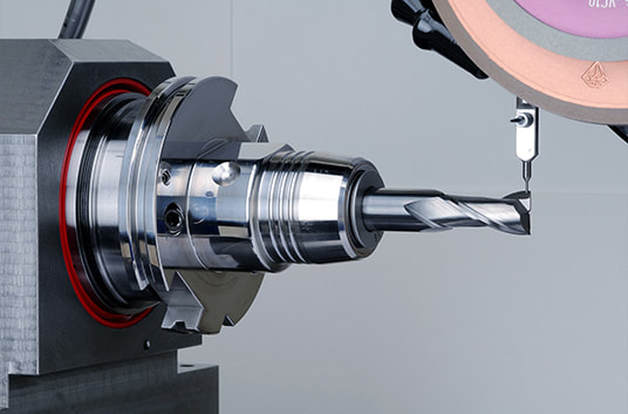

by Kathrin Rehor, MAPAL The machine tool manufacturer bavius technologie gmbh was able to achieve impressive material removal rates of over 20 litres per minute on its new high-end model HBZ AeroCell 160 with a new generation of aluminium high-volume milling cutters from the tool manufacturer MAPAL. The result of this successful collaboration comes at the right time for the aerospace industry, which is taking off again following the downturn caused by coronavirus. The machine manufacturer, which emerged from the Handtmann Group, has been operating as an independent company under the name bavius technologie gmbh since a management buy-out in 2017 and has its headquarters in Baienfurt. Despite all the changes, the business area has remained the same for almost four decades. CNC machining centres are designed and built for the precise high-speed machining of large workpieces made of aluminium. “Over 80 percent of our work is for the aerospace industry, where our AeroCell machines are used primarily to produce large structural parts”, explains Amit Paranjape, Sales Manager at bavius. Customers are aircraft manufacturers and their first and second tier suppliers. Large volumes are required to make full use of the bavius systems. There are currently two different machine lines from Baienfurt. The PBZ profile machining centres are used, among other things, to machine seat tracks for aircraft. The HBZ horizontal machining centres are used to manufacture large structural parts from solid. “Everything long and wide is machined here”, explains Paranjape. “Users can machine all the necessary parts for the airframe of an aircraft on our machines.” The material removal rates are extreme, as one example from a bavius customer shows, who mills out finished parts weighing only 35 kilograms from blanks weighing 1.3 tonnes. Trend towards horizontal machiningThe aerospace industry is undergoing a transformation in terms of machine concepts. After decades of preferring to work on gantry machines or vertical machining centres, horizontal machines are now preferred for new investments, where the components are clamped upright and the spindle is moved horizontally. The main advantage of the horizontal design is the easier removal of the large quantity of chips, which practically fall into the chip conveyor by themselves. At bavius, it’s clear that the aerospace industry has recovered from Covid. Passenger numbers have already returned to pre-pandemic levels and are continuing to rise. As a result, new planes are needed again, which keeps machine manufacturers busy. Demand in Germany, France, Spain and other countries reveals that there is a lot of investment in Europe again. Dynamic machines with high spindle power are particularly sought after. bavius is currently expanding its high-end series HBZ AeroCell with the new AeroCell 160. With a range of mechanical changes, the manufacturer also achieves even greater dynamics with the new machine. Modifications in automation reduce non-productive times. Instead of functioning with hydraulic arms, it is now electrically powered. With the set-up station in front of the machine, a complete pallet change takes two to three minutes. If the pallet is already connected with the part, this takes less than a minute. Tool change has also been optimised with a chip-to-chip time now of 12 seconds. To the limits and beyondThe AeroCell 160 is designed for maximum material removal rates in aluminium. A powerful jet of coolant and a widened chip conveyor ensure that no chip particles can build up anywhere. “Thanks to our concept, we avoid problems that occur with gantry machines. In this way, we can optimally deploy modern tools”, explains Stefan Diem, Application Engineer at bavius. In order to test new machines and at the same time provide customers with references, bavius carries out milling tests that push them to their limits and beyond. “Lots of customers want to see evidence first before they buy a machine”, admits Diem. It is important for the machine manufacturer to use the most efficient tools currently available for the tests, which are then also available for customer demonstrations. bavius regularly tests various manufacturers’ tools. Due to the tight production deadlines, there are not many options. “To save time, it is important for us to have a good exchange with the tool manufacturer”, says Stefan Diem. “We’ve had a good relationship with MAPAL for many years and have always been very pleased with the roughing and finishing tools. I appreciate our close collaboration with MAPAL. We receive excellent advice and are in good hands.” Because milling cutters from the OptiMill-SPM series had previously been used at bavius and performed very well, MAPAL was asked again. It was perfect timing: the tool manufacturer had just finished developing a new solid carbide roughing cutter, the OptiMill-Alu-Wave, and also offered the new aluminium high-volume milling cutter NeoMill-Alu-QBig with indexable inserts for larger diameters. The milling tests are kept simple in design but put the tools through their paces. bavius mills a series of flutes in a large aluminium plate for this. Stefan Diem takes a very pragmatic approach: “if the tool can do the flute, we can also use it to mill pockets and do any other machining.” This means that the determined cutting data can be directly applied to customer parts. The tool could do even moreFor the tests with the OptiMill-Alu-Wave, bavius chose the largest diameter of this three-fluted cutter at 25 mm. At a spindle speed of 25,465 rpm and a cutting speed of 2,000 m/min, the spindle power was gradually increased. Slot number 6 delivered the best material removal rate with a record-breaking 20 dm3/min. This test run was performed with a spindle power of 175 kW, with a torque of 66 Nm, and a material removal rate of 30 mm. The machine stopped during tests at higher powers. “The tool can be fully deployed, the limiting factor is the spindle”, Diem comments on the result. “With the 25 mm OptiMill-Alu-Wave, we have achieved a new dimension in aluminium machining. The milling cutter is definitely better than anything we had previously used.” bavius used the Safe-LockTM system as pull-out protection. “In this speed range, symmetrical pull-out protection is very important in order not to create imbalance”, explains Tim Rohmer, Product Manager Solid Carbide Milling Tools at MAPAL. A Weldon flat, which is often attached to such tools as pull-out protection, is the wrong solution here. To guarantee the smooth running of the machine, there is no way around careful balancing, even with symmetrical tools. The tests in Baienfurt were also met with a great deal of satisfaction in terms of surface quality. The cord geometry of the OptiMill-Alu-Wave ensures optimum chip formation. The polished groove profile ensures seamless chip removal, which is supported by the central cooling of the tool in cooperation with the external cooling in the machine. In further tests, pockets were milled into the aluminium plate, with a material removal rate of 16 litres still being achieved with very good surfaces. For Application Engineer Thomas Jungbeck and Component Manager Alexander Follenweider, who monitored the tests for MAPAL, this is proof of the very good dynamics of the bavius machining centre: “Other machines often stop in the corners and cause high vibrations. This doesn’t occur at all with the AeroCell, which goes round corners almost unrestrained.”  As an indexable insert tool, the new aluminium high-volume milling cutter NeoMill-Alu-QBig from MAPAL is an economic solution for larger diameter ranges. In the tests, the 50-mm milling cutter stood out with a high degree of stability and smooth running. It achieved a material removal rate of 18.4 dm3/min. ©bavius The tests at bavius with the new indexable insert tool NeoMill-Alu-QBig from MAPAL, for which the 50 mm diameter was selected, were also extremely positive.

The aluminium high-volume milling cutter achieved a material removal rate of 18.4 dm3/min. On the machine, the milling cutter stood out with its high level of stability, smooth running and low cutting forces. For use at spindle speeds up to 35,000 rpm, MAPAL fitted the tool body with four threaded bores for fine balancing. The high-precision peripherally ground indexable inserts achieve surface finishes of Ra 0.8 µm and Rz 4 µm during rough and fine machining. They are equipped with a polished chip guiding stage to reduce frictional resistance and heat release. Weight was also saved in order to reduce centrifugal forces. “For larger diameters, milling cutters with indexable inserts are the more economical solution”, explains Heiko Pup, Product Manager for tools with indexable inserts, contrasting the NeoMill-Alu-QBig milling cutters with solid carbide milling cutters. With a 25 mm diameter, the two systems merge. “Some of our customers always go for the more cost-efficient indexable inserts if possible, others prefer to save themselves an extra machining step and continue with the solid carbide milling cutter”, explains Stefan Diem. With different possible radii for its tools, MAPAL provides users with flexibility. With the horizontal machining centre AeroCell 160 and the aluminium high-volume tools, bavius and MAPAL provide users with a combination that takes machining structural parts to a whole new level.

0 Comments

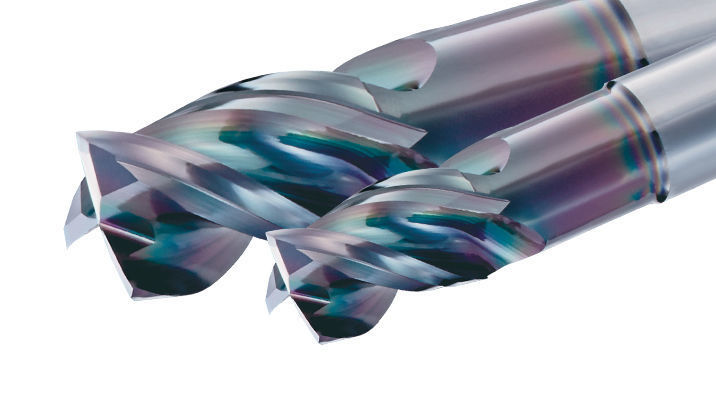

OSG has expanded their A Brand AE-N series! The new additions to their advanced performance DLC Coated end mills, are designed for non-ferrous materials in a wide range of cutting applications delivering efficient and quality processing. The following list numbers are associated with the A Brand AE-N End Mill Series expansion: This series offers the following features & benefits:

A Brand AE-VTS-N (8830)Advanced Performance DLC Coated End Mills for Non-Ferrous Materials. The AE-VTS-N high performance DLC coated carbide end mill for non-ferrous materials is suitable for a wide variety of applications with high efficiency and quality. Its DLC-IGUSS coating further improves tool life with excellent welding resistance and lubricity, which is effective in the machining of non-ferrous materials such as aluminum alloys.  We are very excited to announce that effective October 1, 2017 we will be representing Precision Cutting Tools Inc. in the California and Nevada market areas. Precision Cutting Tools Inc. was founded in 1963 and ever since has specialized in the production of high-quality cutting tools. Today, with over fifty years of experience, PCT is a leading cutting tool manufacturer that distributes its products all across the United States and Mexico. They have based their company’s success on their long-standing commitment to satisfy our customers’ needs, by utilizing the finest raw materials, introducing innovative cutting tools and providing excellent customer service. We look froward to working with them to develop new Carbide, Cobalt & Powdered Metal end mill and drill substrates and geometries that will meet the material cutting needs we find uniquely on the West Coast. We think you are in for a a real treat once we see what we're working on with PCT!!! Farewell & Parting: Next Generation Tooling ends relationship with MA Ford after 22 years.9/29/2017 After 22 years, Next Generation Tooling has ended our relationship as an independent sales agent for MA Ford in the Northern California and Northern Nevada territories. Our last effective day will be September 30, 2017.

We truly appreciate and greatly value our long, successful relationship fostered by both MA Ford and NextGen since the inception of our company. We realize, with no reservation, that the wonderful people at MA Ford were a huge part of our success by working with us to develop technical solutions and will always value our memories and our personal friendships. At the outset of our relationship in the late 1990's, we worked hand-in-hand with MA Ford to introduce their products to the unique applications and high speed machining that takes place in our markets. In conjunction with the MA Ford engineering team we developed the 138 series end mills for use in aluminum and non-ferrous milling. As a result, many other end mill manufacturer's followed in the footsteps of that tool and began developing material specific tooling. Because of the unique needs of our market, we suggested the expansion of LOC and OAL from what was commonly offered in "Stub, Standard, Long & Extra Long" lengths. The 138 series end mills where the first nationally recognized brand to offer 7 different lengths of cuts as stock standard. We are very grateful to everyone at the MA Ford team who has worked with us hand-in-hand for so many years, and wish only the best for MA Ford in the future. Designed for EXTREME aluminum milling! This MA Ford end mill (series 138) is offered in corner radius, square end and neck-relief options. Don't just take our word for it! Watch the video!!

DiACON, a part of M.A. Ford’s Advanced Product Group, features a wide range of high performance, polycrystalline diamond (PCD) tipped tools to improve your productivity in today’s metal, wood and composite material industries. PCD tooling is ideal for more efficient machining of non-ferrous metals, plastics, composite materials, graphite and other hard to machine and abrasive materials. DiACONTM offers end mills, drills, step drills, step reamers and countersinks. Special tools are quoted upon request. According to MA Ford, "DiACONTM is dedicated to continually developing innovative products manufactured with efficient state-of-the-art technology while offering great value and top quality at reasonable prices." The tools will be offered in the following standard configurations. Here are the series names and some information about them.

Here's some of the details on the new tools:  DES (DiACON End Mill Square) Series A straight flute PCD tipped end mill available with 1 or 2 flutes depending on tool size and configuration. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials. A straight flute PCD tipped end mill available from 3 flute to 9 flutes depending on tool size and configuration. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials.  DEB (DiACON End Mill Ball) Series A straight flute PCD tipped ball nose end mill available in 1 or 2 flutes depending on tool size. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber- Reinforced Polymer), fiberglass, aluminum and other very abrasive materials.  DSE (DiACON Spiral End Mill) Series A spiral veined PCD end mill designed with a 30 degree helix (15 degree helix angleavailable as a special). Available in 2 flute for 6mm and 1⁄4” diameters, and 4 flute for larger diameters. A through hole can also be provided as a special on sizes 3/8” (10mm) and above. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiber-glass, aluminum and other very abrasive materials.  84PCD Series A two flute PCD tipped microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. Available in inch and metric sizes and also can be reconditioned for maximum cost per hole.  87PCD Series A three flute PCD tipped microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. The three flute design allows for optimal wear resistance. Available in inch sizes and also can be reconditioned for maximum cost per hole.  83PCD Series A two flute PCD tipped integral pilot microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. Available in inch and metric sizes. Due to the integral pilot design, tools are not typically reconditioned, but can be quoted if needed.  DWD (DiACON Spiral Wafer Drill) The spiral wafer drill offers excellent performance in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials. Available as a special from 1/8” to 1/2” and 3mm to 16mm.  DND (DiACON Nib Drill) Series DiACONTM’s Full Nib Drill has been specifically developed for the drilling of CFRP and CFRP/Metal stack used on all modern aircraft today. The high performance point and fluting geometry greatly reduces separation and delamination in the drilling process. The DiACONTM Full Nib Drill can also be reconditioned two to three times for improved cost per hole. Available as a special in sizes from 1/8” to .354” and 3mm to 10mm. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed