|

Cleveland, OH - Jergens Inc. is pleased to announce the official launch of our new and improved tooling and workholding website! How to Navigate the NEW Jergens Website:Ready to check it out for yourself? Just CLICK HERE!

0 Comments

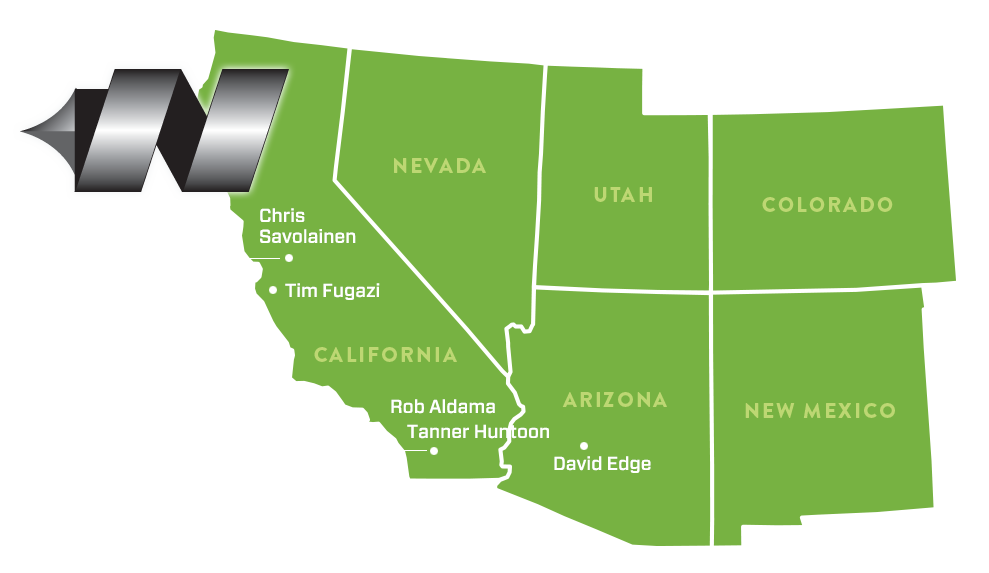

Next Generation Tooling has relocated the Northern California warehouse to a new expanded facility in Lodi, CA, "This new place has a bigger demonstration area than our old facility," said Chris Savolainen, "we can now bring in some CNC equipment to run cutting tools for training and testing. But, more importantly, it has the power requirements we needed to be able to do that." Chris continued. "The biggest feature of the new facility in Lodi is that it is so much easier for customers from the Bay Area and other parts of Northern California to get to us due to its more central location." Get in touch with us is you would like to scheduled for one of our TECHNICAL TRAINING classes!.

Maximize Performance and Functionality With Lathe and Machining Center Tools From Platinum Tooling1/27/2021 Are you utilizing your machine to the fullest? Welcome to 2021! Now more than ever, it is critical to evaluate your manufacturing processes to be sure you are maximizing your current machine tools’ capabilities. Limited turret space?

Platinum Tooling offers a wide range of live, static, and multiple spindle heads to allow for additional cutting tools in the existing space. Drilling and tapping functions become possible from the same turret position. Need more RPM? Speeders for lathes and machining centers, with rpm’s up to 80,000, increase productivity and extend tool life. Optimum speeds and feeds can be achieved by using the correct tool. Do you have a complex angle or hard to reach surface? Universal style tools with angular adjustments, up to 180°, allow for machining at compound angles. Contact us and one of our tooling specialists can discuss ways to improve your machines cycle time and productivity. Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

As companies begin to implement policies to protect from any outside physical interaction in their facilities due to the coronovirus, our entire team as Next Generation Tooling is still available to to meet with you via voice or video call to provide technical support.

To schedule a call with a member of our team just click the button below. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed