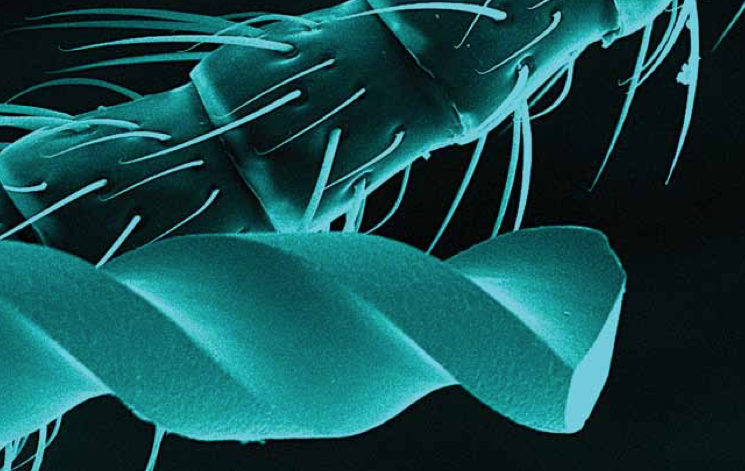

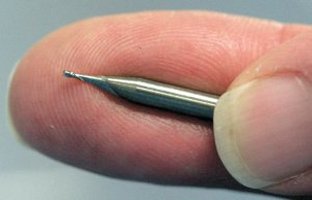

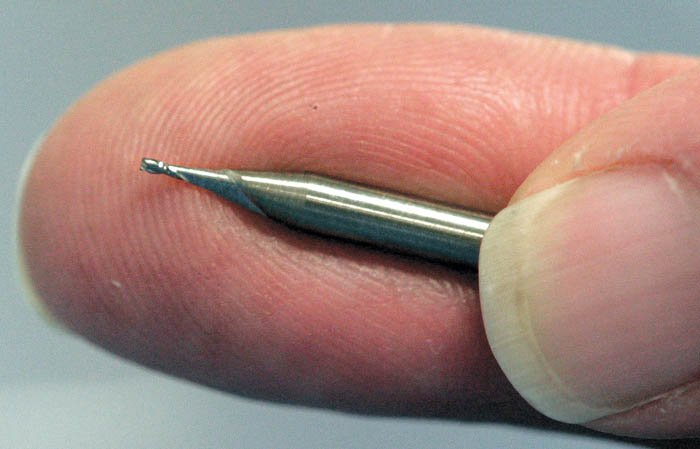

Performance Micro Tool's Unprecedented Advancements in End Mills and Cutting-Edge Applications3/13/2024 Performance Micro Tool first to make the world's first 5 micron end mill. Today, Performance Micro Tool end mills are approaching diameters and tolerances thought impossible just a few years ago. Their unique manufacturing ability has led to many firsts including the world's first 5 micron end mill. PMT's in-stock and custom end mills are used in some amazing applications - from designing medical diagnostic tools for use inside the body to developing micro components for U.S. fighter jets. The PMT product line and unique quality controls assure customers of superior end mill performance and longevity. They also offer the shortest lead times in the industry! PMT Features

PMT Applications

0 Comments

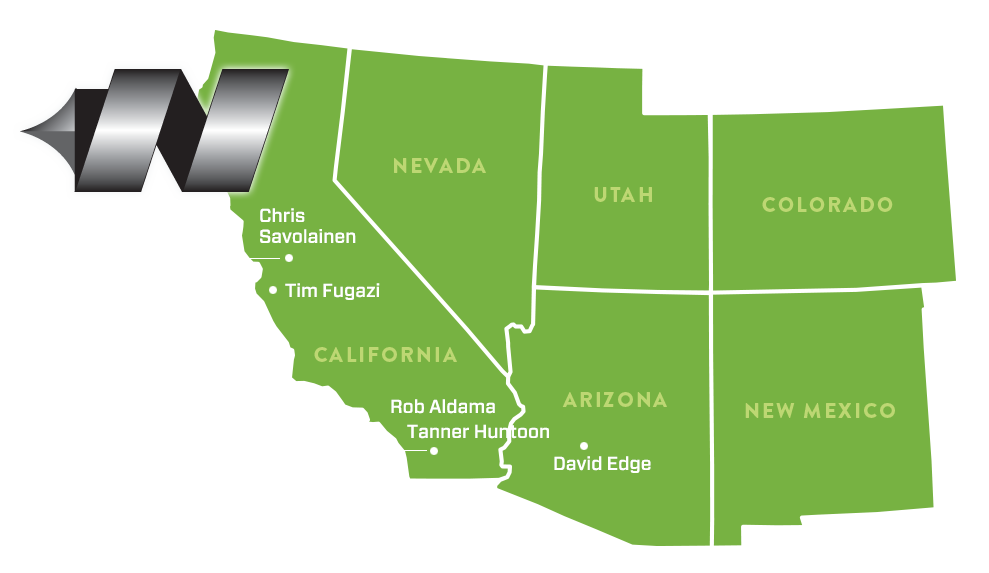

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

This article originally appeared in the Gazette Xtra and I thought it had some great information to pass along to everyone to give you some background on Performance Micro Tool JANESVILLE — As a small Janesville manufacturer, Performance Micro Tool likes to fly under the radar.

Performance Micro Tool's tools have been used to route communications equipment on the Mars Rover project, cut mother of pearl dots on the frets of Gibson guitars and make a harness for a fruit fly. Its tools cut the "plus" and "minus" signs on the sides of 4 million iPhone 4s. Burton said his company prefers a low profile, primarily to keep competitors off guard. That, however, is becoming more difficult. The Wisconsin Entrepreneurs' Network recently named Performance Micro Tool as one of 33 "Wisconsin Companies to Watch." The annual program recognizes companies that demonstrate high performance in the marketplace and exhibit innovative products, services or processes. Performance Micro Tool got its start after Burton watched a progression of big companies pass along ownership of a Janesville facility. The companies started with International Carbide and ended with Kennametal, a huge company with more than 100 facilities. "We were always owned by some out-of-state manufacturer, and in the public sector, the mantra is always the next quarter," Burton said. Kennametal ultimately closed its Janesville shop and shipped the work to a plant in China. Burton and his partner launched Performance Micro Tool. Kennametal soon found that its China plant couldn't do what Performance Micro Tool did, and Kennametal became one of Burton's largest customers. The 12 employees of Performance Micro Tool work across three shifts in a shop on Kennedy Road on Janesville's north side. Machines that robotically grind the tools fill the shop.

"Making them small is certainly our niche," Burton said. "We also do a lot of private labeling, which helps keep competitors off our backs. "We try to keep our prices pretty low to keep competitors from getting into the business and keep them buying from us." Burton credits the company's steady growth to a stable group of dedicated, talented employees, many of who have been with him for years. "These guys will take a bullet for me and this company," he said. "We have an open shop. We're pretty lax and encourage creativity and playing around." Burton said the company pays high wages, covers 100 percent of its health care plan, provides a 401(k) match and often gives bonuses that have included companywide cruises, trips to Cancun and last year involved a Packer-Viking weekend in Minneapolis. "These guys are really concerned about the health of the company," Burton said. "I give them a bonus, and they ask me if I'm sure. "If I wasn't sure, I wouldn't do it. When times are good, we share." Times have been good. A look at the company's growth chart shows a steadily increasing line offset by routine ups and downs. Burton doesn't want to see his company grow too quickly. He knows that fast ups can create fast downs. "If we were to double in size next year, our customer base would suffer, no doubt," he said. In 2009, Performance Micro Tool's sales were off 15 percent when its competitors experienced declines of 45 percent to 60 percent.

"I might tell a customer it will be three days, but my guy on the floor will look at it and say 'I'm gonna knock this out in one day because there's potential here,'" Burton said.

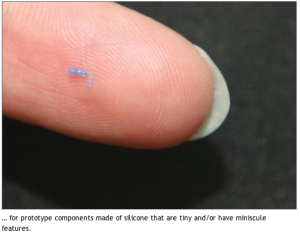

Performance Micro Tool is the definition of innovation, said Phil Jackson, the Wisconsin Entrepreneurs' Network regional director who nominated the company for the award. "These guys are doing cutting-edge work, no pun intended," Jackson said. "And they're not just sitting here in Janesville looking at U.S. markets. They're looking internationally." Here's a story from the east coast that was in Modern Machine Shop not to long ago that we didn't want you to miss… A molder of tiny, silicone components for the medical industry explains how a patient, conservative approach to micromachining enables it to deliver prototypes faster. Article From: 10/12/2011 Modern Machine Shop, Derek Korn, Senior Editor

The pin in the center of this mold component is just 0.01 inch in diameter. In most cases, the single-cavity compression molds (typically machined from aluminum) are used to produce 10 to 100 silicone parts. Although the compression molding process is a manual one that uses hand-loads, it’s still quicker than creating tooling with mechanical or hydraulic actions for injection molding machines. Some molding is performed in Albright’s Class 7 clean room. In addition to providing a detailed white paper on its website about the features and benefits of silicone for medical applications, Albright provides free molded samples, such as the ones above, to show various surface finishes. The samples include machined, bead-blasted and polished surfaces for silicone components. Albright Technologies has become adept at micromachining molds for silicone parts such as the one to the right. This has enabled the company to become effective in quickly generating prototypes for medical device manufacturers pressured to speed new products to market. Many of the silicone components it creates are either tiny themselves or have miniscule features measuring just a few thousands of an inch. What’s interesting is that the company has found it can produce prototypes faster by taking a slower, more conservative approach to micromachining molds using end mills that measure just a few thousands of an inch in diameter. Plus, while one might assume that very high spindle speeds are needed to effectively mill molds using such small tools, the machine that performs micromachining at Albright—a 30-taper VMC—typically spins 0.005-inch-diameter tools at just 9,000 rpm. Although that means feed rates and cycle times are relatively slow, there are a number of reasons why a company focused on quickly turning prototyping work finds this acceptable. David Comeau, Albright’s president, and Robert Waitt, vice president, explained why during a recent visit to the New England-area molder.

Early on, Mr. Comeau noticed that medical device manufacturers needed responsive vendors that could quickly generate small batches of little silicone components for product prototypes. In its first attempt at this type of work, Albright was able to create tooling and present a limited number of prototypes to its customer in just three weeks. This was half the time that the customer’s other vendor could deliver such small parts. Ultimately, Albright created prototypes for 60 iterations of that product, and Mr. Waitt estimates the company saved its customer 1.5 years in development time because of fast prototype turnaround. After that, the customer presented Albright with other similar projects, which ultimately spurred the company to shift its strategy to focus on low-volume, silicone parts production for medical device manufacturers. Today, typical turnaround from receipt of a CAD file to the delivery of parts is only five days.

Here are some of the key elements of Albright’s micromachining process:

The 30-taper Cyclone VMC from Amera Seiki that Albright uses for micromachining was selected for a few reasons, including its price, size, thermal stability and PC-based control. Its small size occupies minimal floor space, and its moving components have less mass to facilitate quicker movements. A cooling jacket around the machine’s spindle helps maintain machining stability, because just a small amount of thermal growth becomes a big issue during micromachining. This is also why the company accurately controls temperature and humidity on its shop floor. The VMC’s PC-based control eases adjustments to parameters such as acceleration and deceleration. The control’s open-architecture platform also simplified replacement of the machine’s original rotary encoders with glass scales. These half-micron-resolution scales deliver precise positioning feedback, which is vital when making micromachining movements. Plus, shop personnel can remotely log in to monitor unattended machine performance.

Given its experience, Albright will replace the tools, based on knowledge of approximate life, before wear becomes an issue. Even though each tool costs approximately $70, the company would rather not risk losing a day’s worth of machining due to unexpected breakage or premature wear just to maximize total cutting time for a tool.

Albright uses balanced toolholders from Techniks, but these are not hydraulic or shrink-fit models. Instead, the company has found that collet-style toolholders that use a setscrew to secure tools work well for its micromachining operations. These toolholders help to provide accurate concentricity, which is important to prevent a micro-tool from taking a deeper-than-anticipated cut and possibly breaking. Plus, while the company experimented with the aforementioned types of toolholders, it didn’t notice any improvement in surface finish versus the collet-style toolholders. Achieving a quality surface finish is important to minimize or eliminate polishing, which can adversely affect dimensional accuracy as well as extend mold manufacturing time.

Consider touching-off micro-tools. Mike Collette, senior tool and die maker, sets up many micromachining jobs. Although he had no prior experience with such small cutters, he’s become adept at manually touching-off tools with tips that he can barely see without magnifying lenses. Of course, it took time to master this art, and he did break some of the costly micro-tools. However, unlike his previous jobs in which there might be hell to pay for mishaps such as that, Mr. Comeau was understanding and accepting. He tolerated some breakage during initial setups because he recognizes how challenging the job is. Without the pressure to be perfect right out of the gate, Mr. Collette was able to establish an effective approach for touching-off tools. Now, breakage during setup isn’t an issue. Mr. Collette has found ways to do it quicker, too. He used to position a tool 0.050 inch or so away from a workpiece before moving in 0.0001-inch increments to bring the tool in contact with the part. This would take almost 20 minutes. These days, he starts closer to 0.004 inch away from the workpiece, meaning fewer increments are required prior to contact. In fact, he’s reached the point in which he can tell whether a delicate end mill touched a workpiece on a “hard” tenth or a “light” tenth. Touching the workpiece with a light tenth means the tool hit the top of a ridge left behind by a previous tool, while the tool hits the true depth with a hard tenth. Trending Smaller Albright is in a good position to succeed, because medical devices continue to get smaller, and silicone is becoming more widely accepted for medical applications. The key for the company is becoming involved with a customer early in the new-product design cycle. Albright focuses on not only providing design for manufacturability input, but also educating its customers about the key properties and benefits of silicone. Albright offers a wealth of information on its company website, but it also offers silicone.pro and matsilicone.com. At silicone.pro, the company blogs about the latest silicone technologies, answers customer questions and encourages other silicone professionals to contribute with blog posts of their own. On the other hand, matsilicone.com is a growing silicone database in which users can search and compare properties of all health-grade silicone materials that are currently available. In addition, Albright provides sample strips demonstrating the types of finishes that are possible with machining molds for silicone. These and other sales tools help the company get its foot in the door with new customers, Mr. Waitt notes. While Albright continues to refine its micromachining processes, it is keeping its eye on additive manufacturing technologies. Mr. Comeau says some of these technologies currently can produce parts in materials that are somewhat similar to silicone, but none can work with actual silicone. This is likely to change as additive equipment manufacturers continue material R&D, he says, and it is leaving the door open to integrating such a process as a complement to its conventional micromachining and molding practices.  Next Generation Tooling is very proud to welcome Performance Micro Tool to our specialized family of CNC products! PMT is a high technology micro carbide tool company that specializes in real world customer performance with results gained through both superior manufacturing processes and second-to-none customer service. It's performance you can measure in microns – and in years. Performance Micro Tool IS the world leader in micro end mills and other micro tools. They have over 30 years of experience in micro engineering, design, and manufacturing. They where the first and only company that to develop a 5 μm end mill! |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed