|

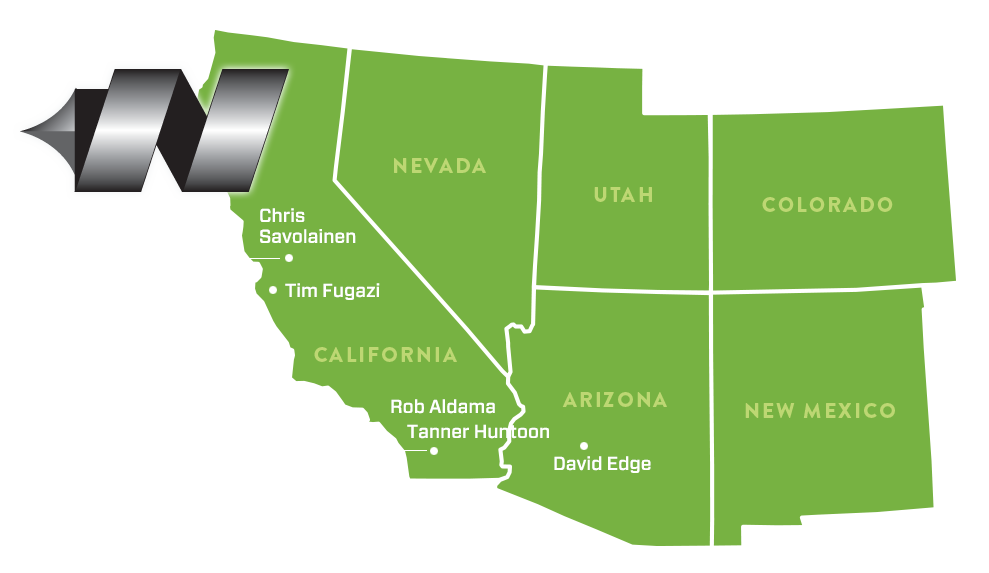

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

3 Comments

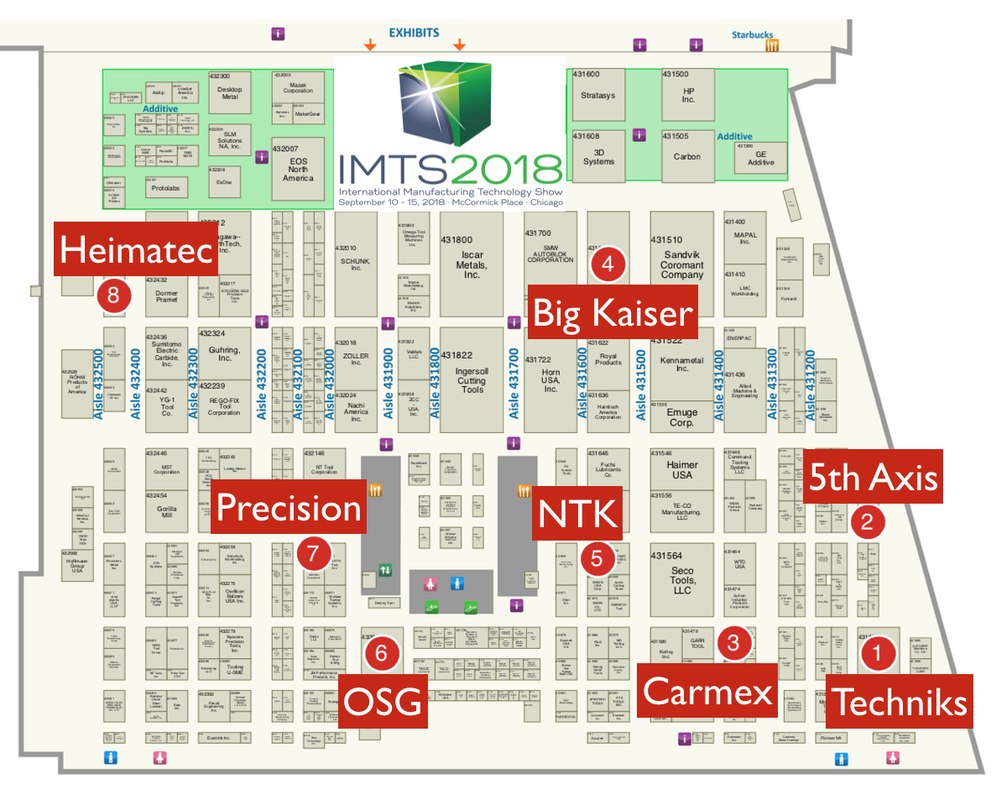

Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075  David Edge David Edge We are very excited to announce that David Edge has joined the Next Generation Tooling team. David has a wealth of experience from his 45+ years in the metalcutting industry. He not only knows the technical aspects of cutting tool applications but also the procedural functions that are important to manufacturers, Industrial distributors and machinery dealers. David began his career in 1972 as a manufacturing engineer in turning applications, with Pneumatic Auto Turret lathes, Tracer lathes and manual Turret lathes. He cut his teeth in sales for 11 years as a cutting tool specialist for Valenite in the Bay area. He moved north to work for RTW and Iscar where he managed Washington, Oregon and Western Canada for the many aerospace applciations in that area. In 2012 he moved back to the Bay area to manage Northern California for Tungaloy. David also brings first hand experience as a distributor from his time at J&L Industrial Supply and Aronson-Campbell Industrial Supply as a carbide application engineer. He has a deep understanding of what the expectations are of a industrial distributor from a manufacturer. David also has an inside knowledge of the expectations of a machine tool dealer from his time back in the late 1980's working at Selway Machine Tools.

We where very excited to meet and greet many of our customers at the 2017 Western Tool & Supply Open House. It was held at their San Jose, CA. on September 21- 22, 2017. We featured quite a few featured products from our principals during the two day event. It was great discussing lots of technical applications that machinists brought to us! Masa Tool has just introduced the F20M10 Cartridge as the latest expansion of the Microconic™ system . The System was developed specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The new F20M10 Cartridge is compatible with spindles that accept Schaublin F20, Southwick & Meister TF20, KEB (MasWerks) MC20, Hardinge TF20 / 4611 collets to name but a few. The Microconic™ system and F20M10 Cartridge has unsurpassed concentricity: Our manufacturing tolerance is 3µm(.0001") and we guarantee our cartridges to be within 5µm (0.0002") in production use in your machine. The F20M10 Cartridge fits the following models of Swiss Machines as well as several others.

Micrograd™ Face Dial Wrench permits accurate clamping pressure adjustment

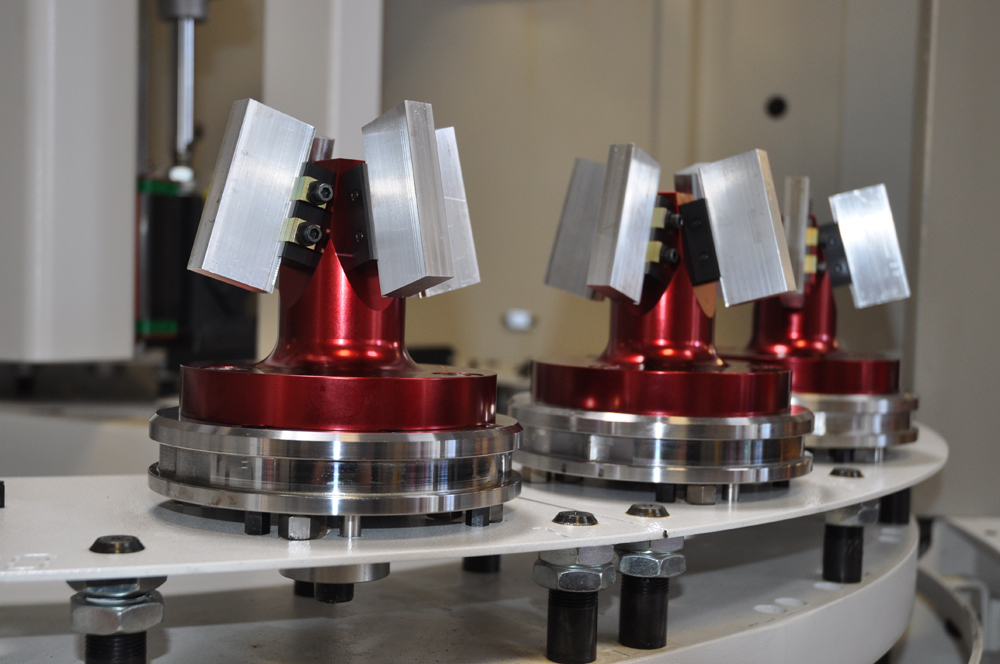

We are very excited to announce a new partnership with 5th Axis Workholding located in San Diego, CA. 5th Axis has created a very nice dovetail workholding system for use in 5 axis milling and can also be used in turning. Please give them a big welcome to out family of principals!  5th Axis Workholding was created out of shear necessity. When Co-CEO’s Steve Grangetto and Chris Taylor started 5th Axis Inc. in 2005, they immediately recognized the need for quality workholding that addressed many of the common issues machinists encounter when moving into the 4th and 5th axis machining. “Fixturing may be the ultimate in problem-solving,” he continues. “If you don’t start with a good, solid fixture – in either 3- or 5-axis work – you’re not going to end up with a good part. More axes just add more layers of complexity.” “A lot of people still aren’t used to thinking in 5 axes when it comes to fixturing,” observes Chris. “They often design them to get a part on and off quickly, without stopping to think about clearance issues.” In 5-axis work, A- and B-axis movement can seriously impact Z-axis clearance. Careless designs invite costly crashes. Longer tools lessen some clearance issues, but introduce problems of their own.

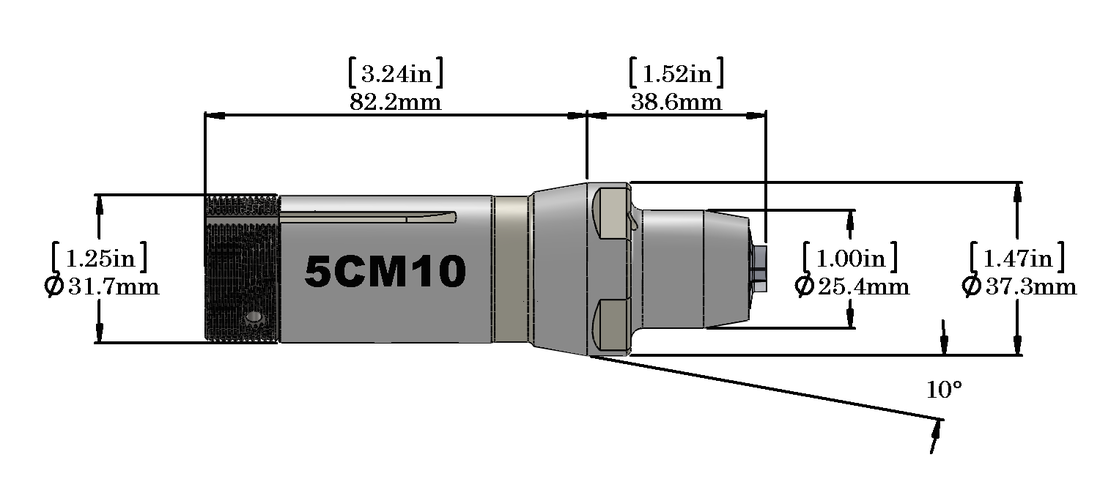

“Fixturing may be the ultimate in problem-solving. If you don’t start with a good, solid fixture – in either 3- or 5-axis work – you’re not going to end up with a good part. More axes just add more layers of complexity.” “When the fixture is right at the beginning,” Steve continues, “we can let the machine take care of most other problems. But, there are one or two areas that require further attention . . .” Masa Tool introduces a 5C Microconic cartridge that maintains 5 µm concentricity and is now available for machining centers, CNC lathes, CNC mills, gang-tool lathes, like Omniturn, CNC mill/turn, like Nakamura, Miyano, Mori-Seiki, and even rotary indexers as well as tool and cutter grinders!

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed