|

Hoffman Estates, IL – BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, introduced Hydraulic Chucks for Swiss lathes in 2018, the first improvement to the technology in more than 30 years. This year, the program has expanded to include inch-size Standard Type chucks, as well as new F Type and R Type chucks.

Standard Type Hydraulic Chucks with tool-side clamping are now available in inch sizes with the clamping range of ø1/8”, 3/16” and 1/4”. The new F Type’s single wrench enables easy cutting tool changes on the tool post. The easy-access rear clamping design is ideal for front tool post. Clamping from the opposite side of the cutting tool and optimum-length design improves overall ease of use. The F Type is available in a clamping range of ø3-10mm and coolant delivery is possible with an Rc(PT)1/8’’ screw. The new R Type eliminates interference at both the upper or lower tool post positions with a unique block design and tightening at an offset position in the tool side. The R Type is available in a clamping range of ø3-10mm and its oil hole drills can be used for coolant delivery when mounted on the upper section. To minimize machine downtime and provide operator safety, these Hydraulic Chucks use a simple hex wrench that requires only two to three turns for both clamping and unclamping. Tightening is complete when the clamping screw hits the bottom; controlling tightening torque is not needed. Once a Hydraulic Chuck is centered, the runout will not vary, even if a cutting tool is changed repeatedly. Runout of fewer than three microns at four times diameter can be achieved. Hydraulic Chucks have a standard pipe thread for coolant-through connection and are available for most Citizen and Star machines with 3/4'’ or 22mm straight shank.

0 Comments

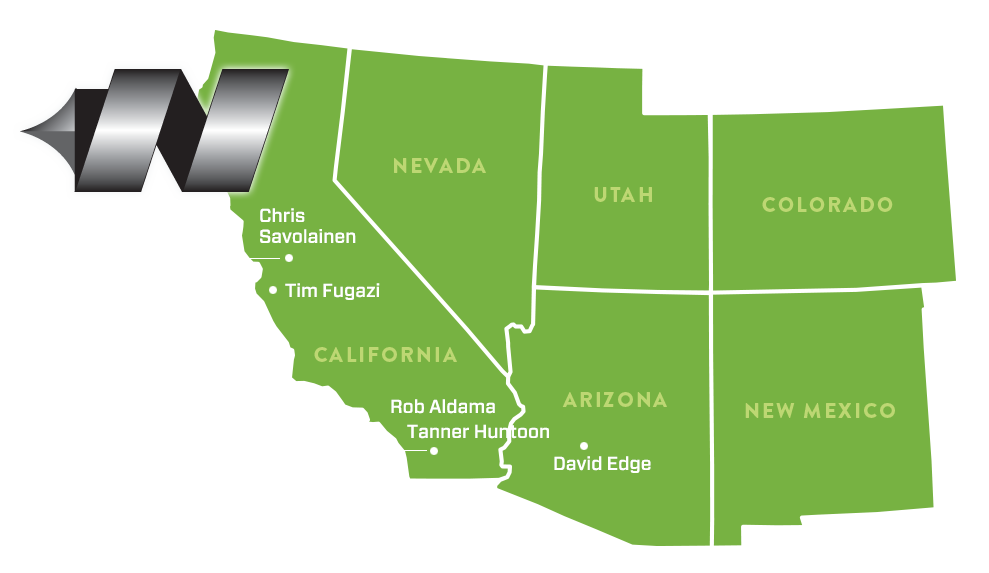

Next Generation Tooling has relocated the Northern California warehouse to a new expanded facility in Lodi, CA, "This new place has a bigger demonstration area than our old facility," said Chris Savolainen, "we can now bring in some CNC equipment to run cutting tools for training and testing. But, more importantly, it has the power requirements we needed to be able to do that." Chris continued. "The biggest feature of the new facility in Lodi is that it is so much easier for customers from the Bay Area and other parts of Northern California to get to us due to its more central location." Get in touch with us is you would like to scheduled for one of our TECHNICAL TRAINING classes!.

Maximize Performance and Functionality With Lathe and Machining Center Tools From Platinum Tooling1/27/2021 Are you utilizing your machine to the fullest? Welcome to 2021! Now more than ever, it is critical to evaluate your manufacturing processes to be sure you are maximizing your current machine tools’ capabilities. Limited turret space?

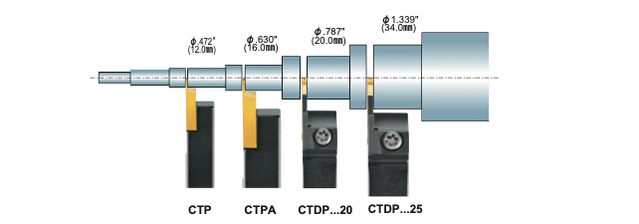

Platinum Tooling offers a wide range of live, static, and multiple spindle heads to allow for additional cutting tools in the existing space. Drilling and tapping functions become possible from the same turret position. Need more RPM? Speeders for lathes and machining centers, with rpm’s up to 80,000, increase productivity and extend tool life. Optimum speeds and feeds can be achieved by using the correct tool. Do you have a complex angle or hard to reach surface? Universal style tools with angular adjustments, up to 180°, allow for machining at compound angles. Contact us and one of our tooling specialists can discuss ways to improve your machines cycle time and productivity. NTK has launched a really sweet Swiss Cut-off Tool Promotion. The promotion runs from December 1, through March 31, 2021. The tooling promotion includes both inserts and holders. CTP / CTPA / CTDP inserts in grades ST4, DM4, QM3 are the focus of this promo, but, if the application material requires different grade, you can use DT4, ZM3, VM1 or KM1 grades when you order. For the holders you can choose between CTP / CTPA / CTDP holders – standard & coolant through, and CTP/CTPA-SUB. The promotion has a limit of 2 sets (insert+ holder) per customer. Simply put:

To qualify for the promotion you must complete the Order Form with: Customer information, Distributor information, Machine information, Current tooling, List the Cut-off insert(s) that will be purchased (item number; grade; EDP#; Qty), the free cut-off toolholder(s). NTK will also need the contact email for the end user because you will get a follow-up Product Survey and, if you complete it, you'll get an NTK wrench set as a gift ! Finally, the Order Form MUST be submitted with the Purchase Order to apply for the promotion. The PO should ONLY be for promotional items. Everything you need to know is in the below promotional brochure! Give us a call and we'll help you get your order placed! Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Platinum Tooling recently announced that it has an extensive line of Heimatec tooling available for the new Haas BMT turret.

NTK introduces TFX Front Turning Carbide Inserts with up to 0.197" Depth Of Cut in a Single Pass12/11/2019 NTK Cutting Tools’ TFX front turning carbide inserts, designed for Swiss-type CNC applications, machines large depths of cut ranging to 0.197" (5 mm) in a single pass. The inserts incorporate a chip-breaker with a sharp cutting edge to optimize chip control and surface finishes. The inserts are available in DM4 (for titanium, cobalt chrome, heat resistant alloys and stainless steels) and ST4 (for stainless steels like 304 and 17-4PH). TFX front turning carbide inserts (wiper style available) with up to 0.197" depth of cut in a single pass, incorporate a special chip-breaker with sharp cutting edge for chip control and surface finishes. Pairing the inserts with a coolant-through holder can improve chip evacuation, surface finish, part tolerance and tool life, says the company. The company’s corresponding TFT series holders have rigid side screw clamping to ensure stable turning by preventing movement of the insert from Z directional cutting forces. TFT series holders have rigid side screw clamping for stable turning, preventing insert movement from Z-directional cutting forces. Pair the TFX inserts with a coolant-through holder (TFT...-OH2) to improve chip evacuation, surface finish, part tolerance, and tool life. The -OH2 style holders are compatible with new coolant-through gangs (Citizen L20 & D25 CNC machines). TFX inserts are available in DM4, for titanium, cobalt chrome, heat resistant alloys, stainless steels, and now in ST4, a super- tough PVD-coated carbide grade. The CrAlN coating provides high hardness and resists oxidation, solving issues related to machining materials such as 304SS, 17-4PH, and Nitinol. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed