|

Yorba Linda, CA – Next Generation Tooling is proud to announce their recent appointment as the exclusive regional managers for Haydale Cutting Tools in the Southern California and Southern Nevada territories.

Haydale Cutting Tools, headquartered in Greer, SC, is a leading innovator in the manufacturing of advanced cutting tools. This partnership signifies a strategic move to enhance the availability and support of Haydale's cutting-edge solutions in the specified regions. Haydale developed the world’s first whisker reinforced tools, and continues to lead in materials engineering and innovation in this category. According to Rob Aldama, Vice President of Next Generation Tooling: "Next Generation Tooling is excited to announce our exclusive agency agreement with Haydale Cutting Tools. This collaboration aligns with our commitment to offering cutting-edge solutions to our clients. Haydale's innovative ceramic tools open new possibilities in precision machining, enhancing efficiency and performance for our customers." Haydale's Silar product offering, renowned for its groundbreaking ceramic cutting tool formulas, includes cutting tool grades such as CT-10, CT-25, and CBN grades SBN550 and SBN570. CT-10 represents a new era in ceramic cutting tool grades, providing exceptional performance in finishing applications for High-Temperature Super Alloys (HRSA's), Irons, and Hardened Steels. Meanwhile, CT-25, a battle-tested ceramic cutting tool grade, is celebrated for its outstanding performance in machining HRSA's, Irons, and Hardened Steels with a hardness of 40+ HRC. The CBN grades, SBN550 and SBN570, are part of Haydale's Silar CBN line, offering versatile and highly efficient tools for various machining applications. SBN570, with its high CBN content, excels in finishing cast irons and HRSA's, ensuring superior cutting performance and extended tool life. On the other hand, SBN550, a low-content CBN grade, is optimized for finishing hardened steels and ductile irons, providing exceptional cutting performance and durability with a focus on cost savings. Next Generation Tooling, as the appointed regional managers, is dedicated to providing comprehensive support and expertise for the Haydale Cutting Tools portfolio. With their established presence and commitment to customer satisfaction, Next Generation Tooling is poised to elevate the accessibility and utilization of Haydale's innovative cutting solutions in Southern California and Southern Nevada.

0 Comments

Next Generation Tooling has relocated the Northern California warehouse to a new expanded facility in Lodi, CA, "This new place has a bigger demonstration area than our old facility," said Chris Savolainen, "we can now bring in some CNC equipment to run cutting tools for training and testing. But, more importantly, it has the power requirements we needed to be able to do that." Chris continued. "The biggest feature of the new facility in Lodi is that it is so much easier for customers from the Bay Area and other parts of Northern California to get to us due to its more central location." Get in touch with us is you would like to scheduled for one of our TECHNICAL TRAINING classes!.

Hoffman Estates, IL – In order to help current and future customers with their inquiries, BIG KAISER Precision Tooling has introduced an easy and convenient way to directly access the company’s experts. LiveChat is available now on BIGKAISER.com.

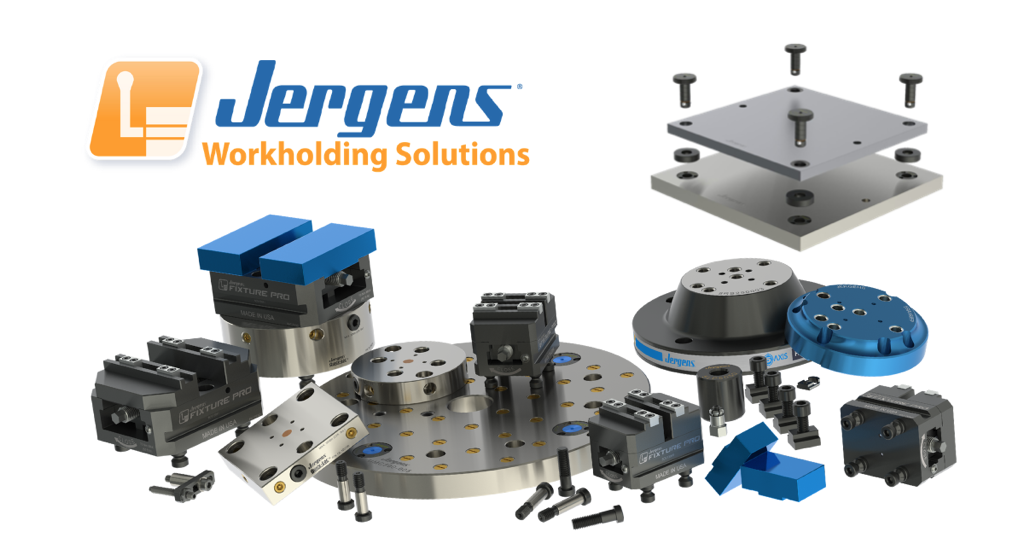

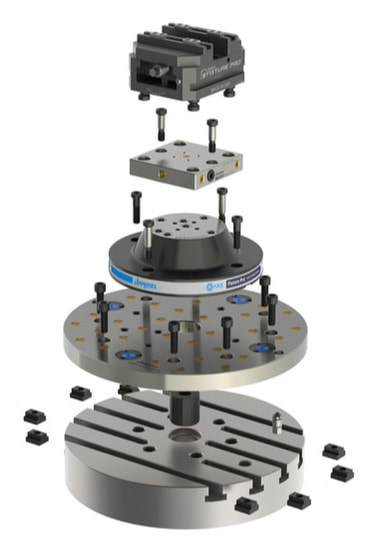

No matter which page a customer is on, you can connect directly and instantly with one of the company’s agents in just a few clicks. Agents will be available during normal business hours and customers can leave a message after hours for help with questions on topics such as: • Application support • Tool presetting • Pricing and availability • Order status • Equipment maintenance • And more Users can save a transcript of their chat for future reference. The chat feature appears on the lower right of any page on BIGKAISER.com. FOR IMMEDIATE RELEASE SACRAMENTO, CA. - Next Generation Tooling is excited to announce that effective November 1, 2020, we will be the exclusive agent for California and Nevada for Jergens, Inc. "We've been working with machine shops for a couple decades now to develop more efficient workholding and fixturing methods and we found ourselves in a position of not having a complete product line of workholding solutions that included manual and hydraulic clamping combined with 5 Axis solutions. Jergens checks off all of those boxes" said Chris Savolainen, President of Next Generation Tooling. Jergens Inc's Long History of Workholding on the West Coast.In 1942, Jack Schron, Sr. founded Glenn Tool and Manufacturing, with his father Christy in Cleveland, Ohio. In response to the needs of wartime production, they began to manufacture standard components in the building next door, with the goal of helping American Manufacturers operate quickly and more efficiently. In 1955 Jergens made their first foray in workholding when the received a patent on the Sine Fixture Key and it become the first of many patented workholding items in Jergens' product line. Jergens has a long history on the West Coast as well. In 1981 Jergens, Inc. acquires California distributor Liberty Industrial Company and developed the first 5 axis vises in the early 2000's in their west coast facility well before anyone else was even thinking about 5 axis machining. In the 90's Jergens developed the Ball Lock® Quick change system and in 2008 acquired Bock Workholding form Joe Cousins, who was part of the original team who created the Chick Workholding vise. In 2011, Jergens, Inc. introduced the Fixture-Pro® Line, which was the first comprehensive, modular system approach to 5-Axis Workholding available. NGT to Represent the Workholding Group of the Tooling Component Division (TCD)In 1987 Jergens created three divisions within the company: Assembly Systems Group (ASG), Jergens Industrial Supply (JIS) and the Tooling Component Division (TCD). The Tooling Component Division (TCD) I comprised of of three groups: The Workholding Solutions Group, the Specialty Fasteners Group and the Lifting Solutions Group.

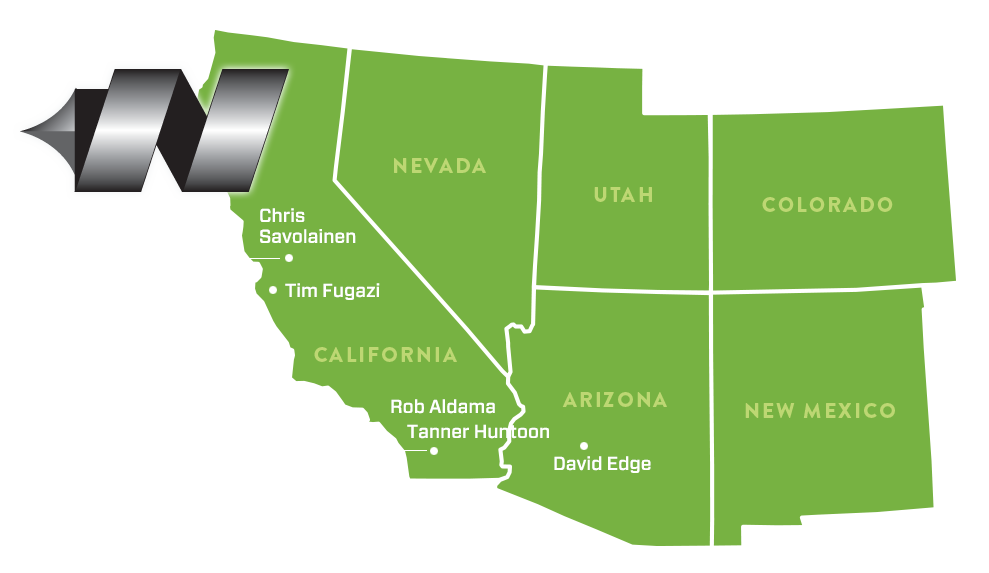

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations. As he grew older he has focused more on martial arts and then specifically on Brazilian Jiu Jitsu. Today tanner enjoys competing and triaining Jiu Jitsu.

At 18, Tanner started work in a machine shop, and since then he's also gotten some sales experience. According to Tanner "I’m excited to combine the two together and grow as a communicator." Tanner's hobbies include Jiu Jitsu, Surfing, hiking. Please welcome Tanner to our team. He's excited to be learning more about all of our principals products at the CNC Spindle. Tanner's new to being a manfacturer's agent, but he's very excited to learn and has an incredibly strong work ethic. He can also bridge the gap between the manufacturer and Industrial distributor as well as the the gap between the manufacturer and machinery dealer. Give him a call, say hello, and get him working on some projects for you! 6669 Mesada Street Rancho Cucamonga, CA 91737 cell: 909.767.2225 [email protected] |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed