|

OSG is pleased to announce the expansion of our PHOENIX® PDZ offering with the addition of the NEW PDZ-3D indexable flat drill.

The following list numbers are associated with the OSG PHOENIX® PDZ Series Expansion:

The PHOENIX® PDZ indexable flat drill offers the following features & benefits:

0 Comments

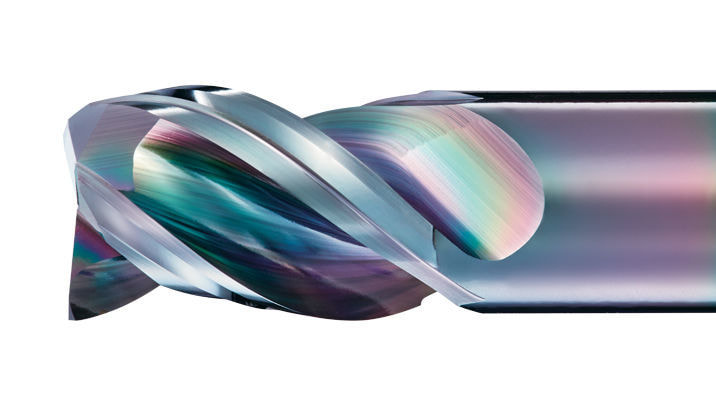

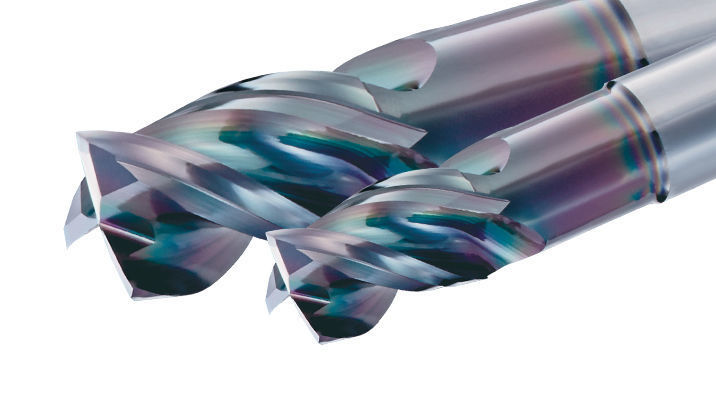

OSG is pleased to announce the expansion of our HY-PRO® CARB VGM end mill series with the addition of the NEW VGM3-AL!

The HY-PRO® CARB VGM3-AL is a is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials. The following list numbers are associated with the NEW VGM3-AL series:

The HY-PRO® CARB VGM3-AL end mill offers the following features & benefits:

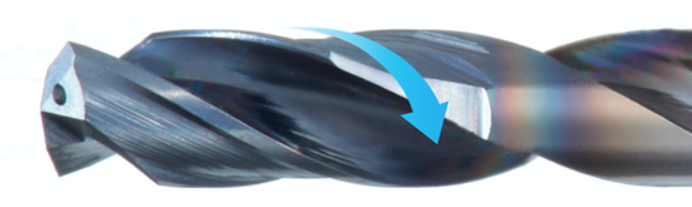

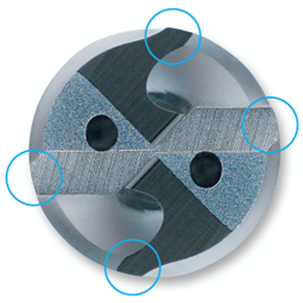

Stable and high efficiency in small diameter deep-hole applications. by Hiroyuki Amano, OSG Corporation Applications Engineer (Drill Development Division) OSG Corporation has recently released the ADO-MICRO – the company’s first small diameter carbide drill with oil holes designed for stable and high efficiency drilling in deep-hole applications. The sense of size upon hearing the phrase “small diameter” will be understood differently among users in the manufacturing industry. The ADO-MICRO has a lineup of drill diameters from 0.7 mm up to 2 mm for drill lengths of 2xD and 5xD, and diameter 1 mm to 2 mm for drill lengths of 12xD, 20xD and 30xD. The product name ADO-MICRO may seem to be associated with the unit prefix micro (µ), but it was named to simply imply smallness in size regardless of the unit. For small diameter drilling, options such as carbide drills and HSS drills using external coolant are available. However, today’s machining needs require greater stability, higher efficiency and longer life than ever before. There is no exception in small diameter deep-hole applications, with growing needs for coolant-through small diameter drills. Tool GeometryOne of the keys for successful small diameter drilling is trouble-free chip evacuation. As illustrated in figure 1, chips generated at the tip of the tool flow in the direction of the blue arrow. However, if there is insufficient space in the flute, cutting chips cannot evacuate smoothly, which causes the drilling accuracy to deteriorate and increases the probability of tool breakage. Therefore, by providing a wider flute specification at the area where the tip of the blue arrow locates, as depicted in figure 1, cutting chips are able to be discharged without difficulty, leading to stable machining.

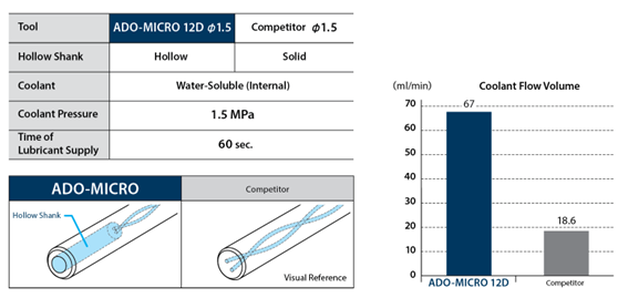

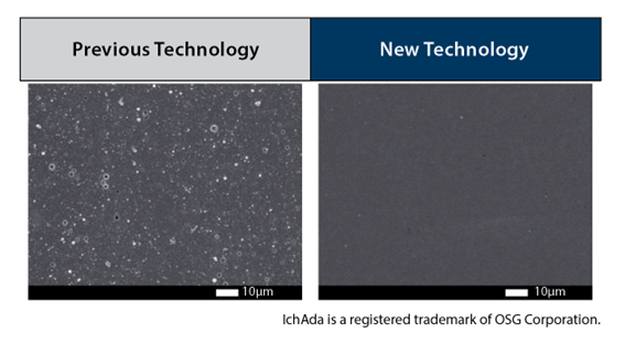

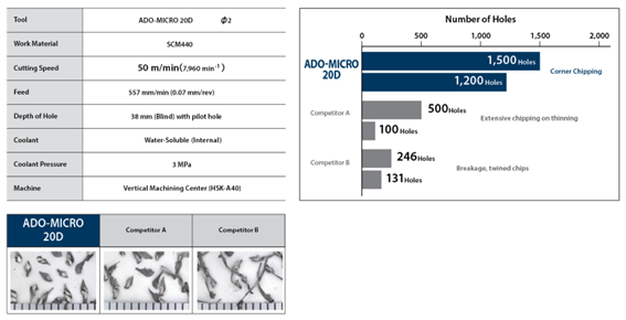

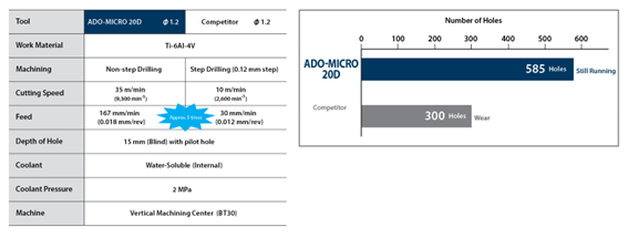

However, micro sludges can be easily accumulated around the outer periphery of the cutting tool, which is a key cause of abrupt tool breakage. To resolve this challenge and to achieve an overall balance, an extended flute configuration is incorporated to provide sufficient exit room as shown in figure 3. Oil HolesThe ADO-MICRO features a straight hollow shank design where coolant is injected in addition to the two spiral oil hole paths. This configuration increases coolant discharge from the tool tip. Without the hollow shank configuration, greater pressure is required in order for the coolant to pass through the thin oil hole paths. With the hollow shank feature, pressure loss is reduced, which increases the coolant flow volume. As illustrated in figure 4, with a higher coolant flow rate, cutting chips can be more effectively evacuated, thereby enabling stable machining. OSG’s Latest Coating Technology: IchAda CoatingAnother key element for achieving stable processing in small diameter deep-hole application is coating technology. The role of tool coating is to provide wear resistance and heat resistance to prolong tool life, which is particularly important to small diameter tooling. As illustrated in figure 5, the coating surface by conventional technology is not smooth, which may interfere with the performance of chip evacuation. OSG’s latest IchAda coating, on the other hand, provides excellent surface smoothness in conjunction with high wear resistance and heat resistance to enable small diameter tools to achieve long tool life by improving adhesion. Cutting DataFigure 6 demonstrates a comparison of tool life between the ADO-MICRO and two other tooling manufacturers’ products in the machining of SCM440. The competitor drills have chipped or have broken at the initial machining stage. The ADO-MICRO, on the other hand, was able to achieve long tool life stably due to its superior chip evacuation capability by breaking chips into small and manageable pieces. The ADO-MICRO demonstrates stable performance even in difficult-to-machine titanium alloy applications. As shown in figure 7, the competitor drill struggled with chip evacuation, thus requiring step processing. However, with the ADO-MICRO, step processing can be eliminated while achieving approximately five times the drilling efficiency. The ADO-MICRO was still in good shape after doubling the competitor drill’s tool life, allowing it to be used on other applications. The ADO-MICRO’s unique tool geometry and OSG’s original IchAda coating allow non-step drilling even for deep-hole applications, enabling high processing efficiency.

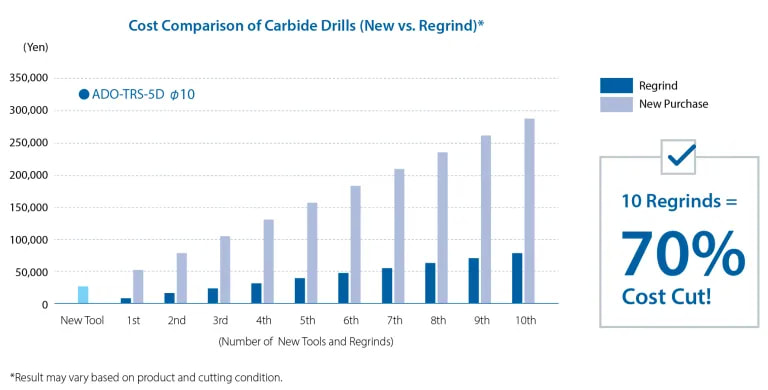

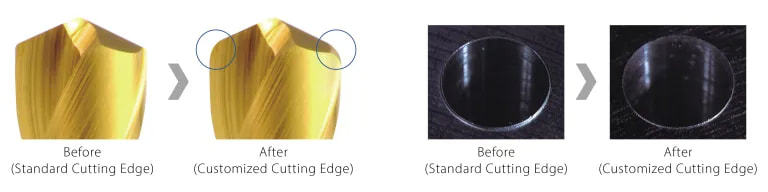

By eliminating common complication in small diameter deep-hole drilling, the ADO-MICRO is able to excel with stable performance in a wide range of work materials including stainless steel. In addition to standard stock items, OSG also offers customization services with tailored solutions for each and every manufacturer’s specific machining needs. Enhancing sustainability by tool reconditioning and recycling services by Masatoshi Kageyama | OSG Corporation As a global company manufacturing responsible products, OSG is committed to a healthy planet and society. In order to reduce environmental impact, OSG actively implements initiatives relating to resource and energy conservation, waste reduction, prevention of pollution, and material recycling in various processes throughout the OSG Group. OSG’s tool reconditioning program is a part of the company’s commitment to promote resource conservation and to improve energy efficiency in its business activities. The primary benefit of tool reconditioning is obvious: reduction in overall tooling costs. Although many shops regrind their own drills, few shops have given thought to regrinding high performance cutting tools, even though substantial cost savings can be obtained. These efforts not only save customers thousands of dollars each year but are also environmentally friendly and sustainable. As a comprehensive cutting tool manufacturer, OSG is capable of regrinding and recoating an array of products, such as solid carbide tools, HSS tools, PCD tools, rolling dies, specials, and more. Tool reconditioning services provided by OSG restore used tools to like-new condition. OSG’s tool reconditioning division uses original OSG manufacturing drawings for all regrinding processes. OSG Group companies also adhere to the OSG quality control manual and use the same inspection equipment used by the manufacturing division during the inspection procedures. With tool reconditioning facilities in 14 countries, OSG can respond to customer needs worldwide. In addition to tool reconditioning, OSG also offers customization services to help manufacturers optimize machining based on individual application needs. OSG USA's Regrind CapabilitiesOSG USA has comprehensive Regrind and Coating Capabilities for Drills, End Mills, Reamers, Taps and more! Get the best coating based on your application and tool. Additional Coatings available. Drills

End Mills

Reamers

How to Get the Ball RollingEvaluation Services Tailored for Your Needs

To begin, contact your nearest Next Generation Tool regional manager to set up an evaluation appointment. We will evaluate each and every one of your application before sending the tools off for reconditioning. OSG has expanded their A Brand AE-N series! The new additions to their advanced performance DLC Coated end mills, are designed for non-ferrous materials in a wide range of cutting applications delivering efficient and quality processing. The following list numbers are associated with the A Brand AE-N End Mill Series expansion: This series offers the following features & benefits:

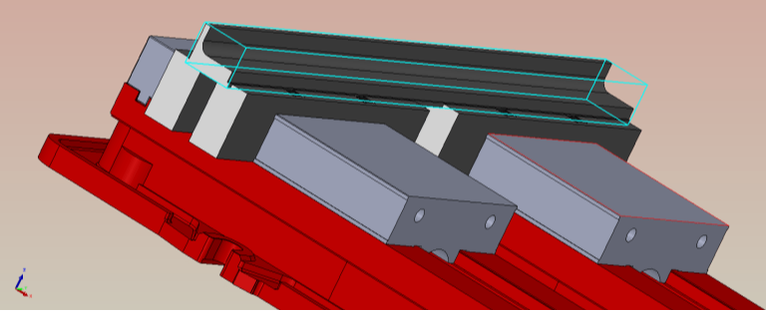

A Brand AE-VTS-N (8830)Advanced Performance DLC Coated End Mills for Non-Ferrous Materials. The AE-VTS-N high performance DLC coated carbide end mill for non-ferrous materials is suitable for a wide variety of applications with high efficiency and quality. Its DLC-IGUSS coating further improves tool life with excellent welding resistance and lubricity, which is effective in the machining of non-ferrous materials such as aluminum alloys. OSG is pleased to announce the release of their NEW OSG PHOENIX® PDZ Flat Drill Series!

The OSG PHOENIX® PDZ is an indexable drill series designed for stable flat-bottom hole making. It is an ideal solution for a wide variety of materials such as carbon and alloy steel, stainless steel and cast iron. The following list numbers are associated with the new OSG PHOENIX® PDZ Flat Drill series:

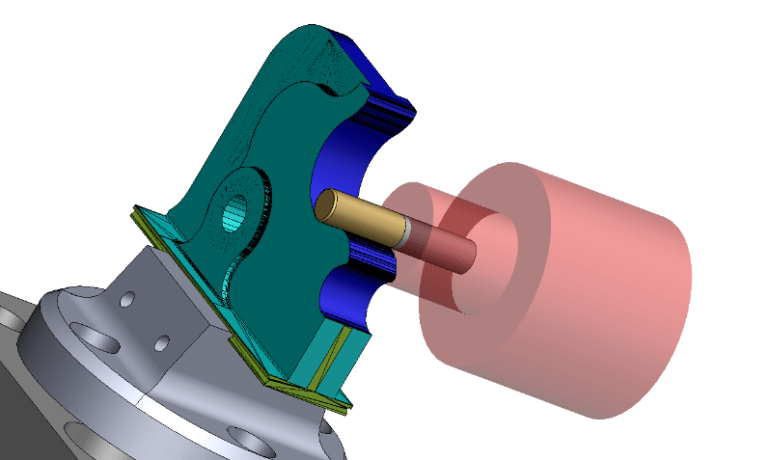

by Sean McIntosh, OSG District Sales Manager OSG’s HY-PRO® CARB VGM end mill boosts productivity and lowers cost per part in aerospace bracket application. Founded in 1951 in Phoenix, Arizona, United States, Allied Tool & Die Co. is a family-owned precision machine and fabrication company that specializes in the manufacturing of quality parts for aerospace, medical, communications and commercial industries throughout the world. Seventy years since its establishment, this privately owned shop has grown with multiple facilities and an estimated 32,000 square feet of manufacturing space in Phoenix, Arizona. One of the challenges Allied Tool & Die faced recently was the machining of aerospace brackets made of Inconel 718. As is with most shops, machining Inconel 718 is time consuming. Moreover, due to the material’s special high strength and heat resistance properties, short tool life is a common obstacle. In search for performance improvement, Allied Tool & Die CNC Process and Machining Manager Jamie Lerma reached out to his local OSG representative for new solutions. Lerma had worked with OSG previously on a 13-8 stainless steel application by utilizing OSG’s HY-PRO® CARB VGM series end mill to achieve high-efficiency milling. OSG’s HY-PRO® CARB VGM is a high performance variable geometry end mill series. Its variable index and unique flute geometry enable the reduction of vibration and chatter, promoting smooth and stable cutting with low cutting forces. With the addition of OSG proprietary multi-layer EXO coating, higher wear and heat resistance is achieved to prolong tool life. OSG’s VGM offering features 5-, 6- and 7-flute lineups, and is available with multiple lengths of cut, with both square end and corner radius variations. This series is suitable for carbon steels, alloy steels, die steels, stainless steels, cast iron, nickel alloy, titanium, and hardened steels up to 45 HRC. For the 13-8 stainless steel application, the VGM end mill dominated the machining result by extending tool life from seven parts to 21 parts per tool. The parts were also completed in half the time and the tool cost is also cheaper than the competitor tool. Lerma was so impressed by the VGM end mill that he decided to apply the tool to the Inconel 718 aerospace bracket application. Allied Tool & Die was previously using a high feed indexable milling cutter for the Inconel 718 aerospace bracket application. However, the amount of time and money spent on changing the inserts was less than desired.

The previous competitor tool was used at 150 SFM (45.7 m/min), 0.009 IPT (0.23 mm/t), 0.05 Aa (ap = 1.27 mm) and 0.75 Ar (ae = 19.05 mm). After reprogramming to utilize OSG’s 0.5-inch diameter 5-flute VGM carbide end mill with a 0.030-inch (0.762 mm) corner radius and 1.25-inch (31.75 mm) length of cut (EDP# VGM5-0143), the cutting parameters were changed to 250 SFT (76.2 mm/min, 2,548 min-1), 0.0022 IPT (0.056 mm/t, 713 mm/min), 0.75 Aa and 0.035 Ar. The application went from a 4-hour cycle time to just one hour and 45 minutes. Allied Tool & Die no longer had to keep stopping the machine to rotate or change inserts, which they were doing four times per part previously. By switching to the VGM end mill, the tool was loaded, and the job did not have to be tended to until the part was completed. In terms of efficiency improvement, Allied Tool & Die estimated that the tool change has generated a cost savings of $6,875 USD on the Inconel 718 aerospace bracket parts. Moreover, with a lower tooling price versus the previous milling cutter, the cost of tooling also decreased by almost $100 USD per part. With the VGM end mill, Allied Tool & Die was able to machine Inconel 718 at an astounding 250 surface feet per minute (76.2 m/min) – a speed that is only commonly seen in alloy or stainless steels, not HRSA materials. With the recent successes, Allied Tool & Die’s CNC Programmer John Hernandez decided to apply the VGM end mill into most jobs he programs. Being such a versatile tool, the VGM can be used to machine anything from common carbon steels up to the nickel alloys required by the aerospace industry. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed