|

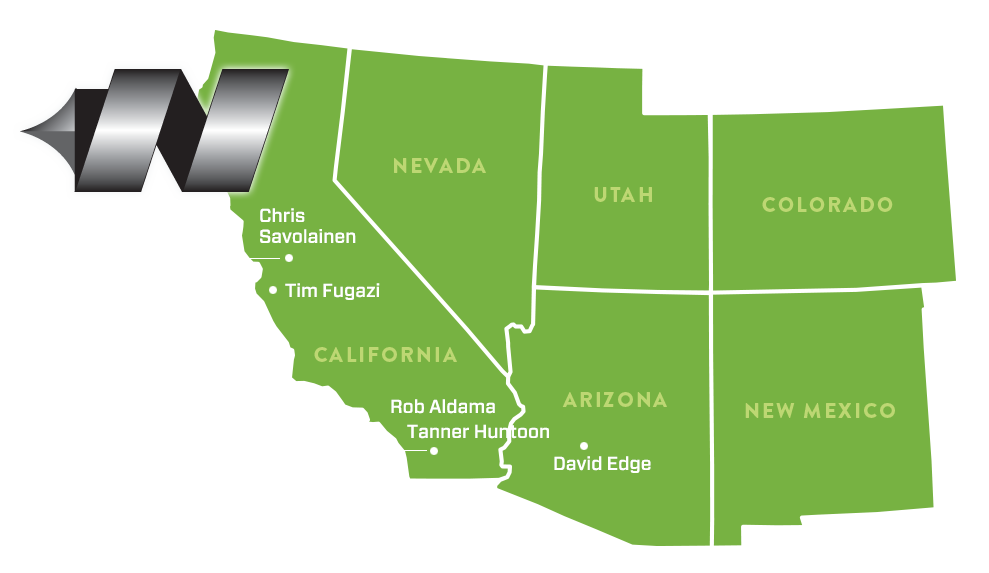

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

3 Comments

Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations.  David Edge David Edge We are very excited to announce that David Edge has joined the Next Generation Tooling team. David has a wealth of experience from his 45+ years in the metalcutting industry. He not only knows the technical aspects of cutting tool applications but also the procedural functions that are important to manufacturers, Industrial distributors and machinery dealers. David began his career in 1972 as a manufacturing engineer in turning applications, with Pneumatic Auto Turret lathes, Tracer lathes and manual Turret lathes. He cut his teeth in sales for 11 years as a cutting tool specialist for Valenite in the Bay area. He moved north to work for RTW and Iscar where he managed Washington, Oregon and Western Canada for the many aerospace applciations in that area. In 2012 he moved back to the Bay area to manage Northern California for Tungaloy. David also brings first hand experience as a distributor from his time at J&L Industrial Supply and Aronson-Campbell Industrial Supply as a carbide application engineer. He has a deep understanding of what the expectations are of a industrial distributor from a manufacturer. David also has an inside knowledge of the expectations of a machine tool dealer from his time back in the late 1980's working at Selway Machine Tools.

We where very excited to meet and greet many of our customers at the 2017 Western Tool & Supply Open House. It was held at their San Jose, CA. on September 21- 22, 2017. We featured quite a few featured products from our principals during the two day event. It was great discussing lots of technical applications that machinists brought to us!

We got to spend a few days in Chicago to get a great preview of some of the newest products and innovations for the kind of machining we do on the West Coast.

There's some really informative videos on quite number of the products so be sure and give yourself some time to watch them.

5th Axis - Duece Vise

Use as a single or double station fixed jaw vise. Two vises for the price of one.

The small footprint allows for multiple units to be ganged together on vertical or horizontal machines. BIG KAISER - EWD EVO Digital Head EWD EVO digital boring head EWD EVO digital boring head

BIG KAISER is continuing down the path of digital tooling innovation with the introduction of the EWD EVO, a digital boring head designed with a single goal in mind—making the life of an operator as easy as possible.

It will be synched with the new BIG KAISER smartphone and tablet app, which was developed to enhance user friendliness while assembling and running BIG KAISER boring tools. Not only will you be able to read the cutting diameter change, but the app will also help operators determine optimal cutting parameters from their tool assemblies. The app will also log historical adjustments for all tools ever synched with it, a critical piece for shops joining the smart manufacturing movement. Heimatec Offers Machine Brand-Specific Tooling

Heimatec Inc. spotlighted its complete line of live tools and showcased them at IMTS in a series of four new catalogs. Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database,

MA Ford - CDA Aluminum Coolant Drill

MASA - F20M10 Cartridge

Check out the video! Matt Saccomanno discusses the Microconic Workholding system at IMTS 2016.

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine.

The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter. mPower - Spin Select

Read this section or just watch the video! The SpinSelect Multi-Pocket Selectable Tool Holder was created to increase productivity and consistency by decreasing downtime associated with tool and insert setups and changovers.

Designed for use on most lathes having a turret or tool post, SpinSelect™ offers significantly better throughput on machining tasks such as heavy roughing, harder material removal, and short runs. Machining operators have seen up to an 85% savings on changeover/setup times as SpinSelect creates a nearly continuous runtime with offline insert changes/reloading.

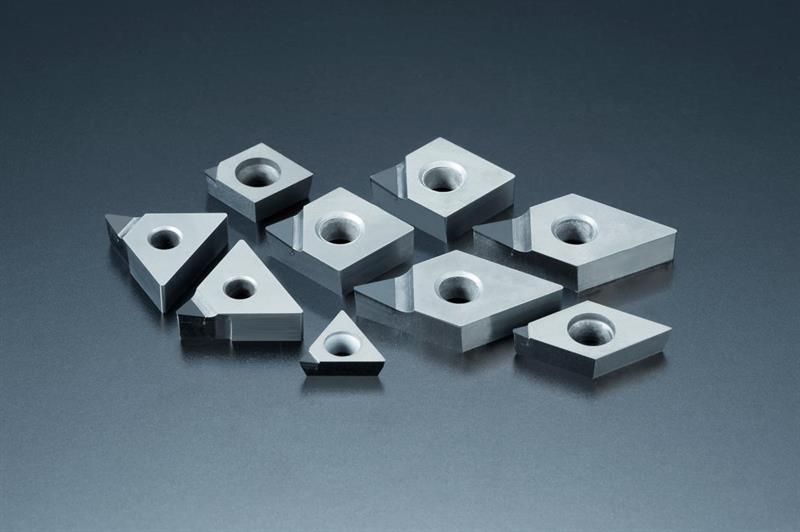

NTK - PD2 Super Micorgrain PCD Inserts

The high speed turning of aluminium alloys and non-ferrous materials has now been taken to a new level with the introduction of the NTK PD2 insert line. With exceptional edge sharpness and adhesion resistance, the new PD2 range of inserts are ideal for extending tool life and productivity on difficult to machine alloys.

Furthermore, the edge toughness and composition give the PD2 tool life and consistency that is unrivalled when conducting interrupted and continuous machining.  NTK PD2 PCD tipped Carbide Insert NTK PD2 PCD tipped Carbide Insert

The new PD2 is available as a positive insert with a CCMT, DCMT and TPMT geometry that provides a PCD cutting edge length of 2.3mm with the option of a 0.2 or 0.4mm corner radius. The various insert geometries and available with an insert thickness from 2.4 to 9.5mm.

Complementing the positive geometry inserts is a complete selection of negative type inserts for the PD2. The CNMX, DNMX and TNMX geometries have a cutting length of 3.4, 4.5 and 3mm respectively and all inserts have a 4.76mm thickness that promotes strength and rigidity. The three insert types are available with a corner radius of 0.4 or 0.8mm to prevent edge breakages and prolong tool life and consistency. Both the positive and negative type single cutting edge inserts are available with a range of toolholder designations to suit all types of turning centre from the smaller sliding head centres through to heavy duty turning machines. OSG - Exopro Aero Series for Composites

A variety of cutting tools exhibited included the new EXOPRO AERO end mill series for composites.

Ever dream of machining composites without delamination and tool life issues? Composites are constructed with layers of material that are prone to delamination. They are also known to be abrasive and could easily wear your tool down. If your tool loses its sharpness, the material gets pushed away instead of cut, producing uncut fibers. OSG’s EXOPRO® AERO-BNC routerovercomes these problems and even provides high feed roughing and a superior finish.

Longer Tool Life

The AERO-BNC also features OSG’s patented diamond coating which has a maximum diamond grain size diameter of 2μm. This ensures our coating is super smooth. Unlike our competition, we manufacture all diamond products in-house using our grinding technique on our special carbide substrate. This patented diamond coating coupled with the AERO-BNC router’s thick core diameter and multiple flutes extends tool life significantly. Improved part finish and sharper cutting edges are also the end results of the diamond coating. Versatility The AERO-BNC is extremely versatile and can be applied in both thick and thin laminates. It is versatile enough to handle trimming, slotting and shoulder milling applications! It also can engage parts by plunging, ramping or helical entry and is available in various end cuts to enable you to find the right tool for your job. Techniks - Hydraulic Holders

The International Manufacturing Technology Show is one of the largest industrial trade shows in the world, featuring 1,900 exhibitors and 100,000 visitors. The event is held every two years in September at McCormick Place, Chicago.

Don't miss out on the biggest show in Manufacturing - Register today! On-site registration is open Monday, Sept. 12 through Saturday, Sept. 17 in all four buildings of McCormick Place. Tooling & Workholding Systems Pavilion in the West Building is open 9:00 a.m. - 5:00 p.m. Several of our Principals will have products on display at IMTS 2016. Below is where you can find them at the show.

Pavilion: Tooling & Workholding Systems

Let us know if you're attending and let's make plans to meet each other in Chicago! At the September 2014 IMTS show, Emmett Quigley, the Manager of the Airborne Instrument Development Lab at NASA Ames Research Center, was looking for a modular workholding system that would help him to quickly change over the fixturing on his table to meet the lab's demands of rapid prototyping and development.

Demanding design requirements for future developmentQuigley had several initial requirements:

Emmett looked at a couple of systems but post IMTS only mPower had followed up with the information he needed to start the design. He found that the Modern Industries mPower modular tombstones and fixturing systems would meet his needs, but would need some customization to truly get the maximum use of his machines table space and travels. The mPower system was to be implemented on two machines to begin with. The first would be the labs workhorse, a Deckel MAHO DMU70V. The next machine would be a Deckel Maho MH600C Universal Milling Machine. The MAHO is unique in that it has both a horizontal and vertical spindle as well as a full fourth axis capability. After several email exchanges and design discussions with regional manager Chris Savolainen and Ron Bemis, the Application Engineer at Modern Industries the team spent from from October 15th through 17th reviewing the various part shapes and size requirements to define the subplate hole locations that would provide the very best versatility to meet the needs of the lab.

It was decided to go with 2" x 2", 1/2 -13 bolt hole pattern in 1.5 “ thick aluminum plates. However they needed to modify the DMU plate by adding the through hole so they can reach the table with their tool setter. Quigley then need to duplicate the plates in steel. The final requirement was that the lab needed to have the locating/clamping features below the surface as these plates will need to be surfaced from time to time. Due to budget constraints the system had to be developed with consideration for the longer term lab requirements so that it could eventually expand for upcoming new projects. Preparing for the unknown problem has always been part of the mission at NASA so long term contingency planning is the norm. In June of 2015, phase one of the project was implemented on the Deckel Maho DMU70V machine. Quigley's thoughts on the implementation thus far: According to Savolainen "NASA's Airborne Instrument Development Lab at Ames really considers both current needs and future needs when they look at workholding systems. The machines and equipment have to be versatile enough to handle current projects but also new research projects that might not even exist until 10 or 15 years from now. They really put a great deal of thought into products before they get them and it's actually a real pleasure to work with engineers who plan and think so far into the future!" |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed